Meyer Sound Weather Protection

The Weather Protection option from Meyer Sound is intended to increase the useful life of Meyer Sound loudspeakers when they are installed outdoors and exposed to different and often harsh weather conditions. Our Weather Protection includes a penetrating treatment to raw wood, use of special primers, and plating on all steel parts used (or alternatively, the use of stainless steel hardware). Weather Protection is designed to prevent malfunctions caused by harsh operating environments and slows the accelerated wear and tear that occurs in outdoor environments.

When Is Weather Protection Advisable?

Weather Protection is strongly recommended for all permanent outdoor installations where loudspeakers are directly exposed to the elements. This includes desert and semi-arid climates, where protection against dust and sand is important, and where infrequent rainstorms can contribute to deterioration of loudspeaker components.

Weather Protection is also recommended when the loudspeakers are sheltered from direct exposure to precipitation but are nevertheless exposed to prolonged high humidity, fog or mist. Examples would be installations on covered outdoor terraces or pavilions

Weather Protection is further advisable for portable or touring systems when any significant outdoor use is anticipated. Even though standard procedures may call for using external protective measures, these are often not implemented in time to prevent moisture intrusions that could lead to premature performance degradation of the loudspeaker.

Climate Variation and Owner Maintenance

The wear and tear on a loudspeaker will vary significantly with different climatic conditions. For example, a weather protected loudspeaker installed in a sunlight-exposed location on an ocean pier will experience much harsher conditions than a loudspeaker in a similar installation that is shaded by trees and exposed only to rainfall. The constant exposure to direct UV radiation and salt air environment will cause a loudspeaker to wear more quickly than one with partial UV shielding and exposed only to freshwater moisture.

Wear can eventually affect the performance of the loudspeaker. It also affects aesthetics. For example, in salt air environments, the exterior grille can quickly show signs of oxidation, causing unsightly discoloration.

Apart from selecting suitable weather protection, the progress of wear and tear on the loudspeaker can be slowed by a regular schedule of inspection and cleaning. This maintenance is particularly necessary in harsh environments. Inspection and cleaning should include routine removal of any visible oxidation or environmental particulates, as these can accelerate metal corrosion or decay of the cabinet. If installed loudspeakers are not in use for an extended period, exterior protection or temporary removal and storage of the loudspeakers should be considered.

Benefits of Weather Protection

There are several benefits to selecting the Meyer Sound Weather Protection option:

Functionality - Weather Protection prolongs the service life of the loudspeaker by preventing premature degradation of internal components.

Safety - Weather Protection lessens the chance of electrical malfunctions or structural failures.

Warning

IT IS THE RESPONSIBILITY OF PURCHASERS/USERS/OPERATORS TO SELECT WEATHER PROTECTION WHEN APPROPRIATE FOR THEIR USE AND TO PERIODICALLY INSPECT THEIR LOUDSPEAKER INSTALLATIONS FOR ANY DETERIORATION THAT MAY LEAD TO SAFETY CONCERNS.

Aesthetics - Weather Protection slows wear and tear on the exterior of the loudspeaker in harsh conditions. Early signs of wear and tear on the exterior of the loudspeaker indicate over-exposure to the elements.

Standards Compliance - Weather Protection helps in meeting IP ratings for loudspeakers. IP ratings are an internationally recognized standard often used in installations involving our products. A further explanation of IP ratings is given in the IP Ratings.

Weather Protection Components

Standard Weather Protection

Meyer Sound designs toward an IP rating of IPX4 (see IP Ratings) for Standard Weather Protection, which includes the following components:

Wood treatment — Prior to cabinet manufacturing, the raw wood receives a special treatment that penetrates and stabilizes the wood fibers to withstand a wide range of temperatures and exposure to extreme humidity.

Cabinet finishing — The assembled cabinets receive a highly impervious finish that includes a sealing primer and a finishing topcoat. The coatings are applied on both surfaces, with one coat on the interior and two on the exterior. The final step is a two-part modified acrylic urethane similar to that used in military applications.

Driver treatment — All cone drivers are coated with a water-resistant sealant.

Exterior protection — Grille frames are coated to resist corrosion, and all components that mount to the cabinet use custom gaskets and stainless steel fasteners.

Removable rain hood — The rain hood is designed to shield connectors even in wind-driven rain.

Ultra Weather Protection

For installations in extremely harsh environments, Meyer Sound offers an Ultra Weather Protection option on a limited number of loudspeaker models. (For a list of products offered with this option, please contact Meyer Sound.) Meyer Sound designs toward an IP rating of IPX5 for Ultra Weather Protection, which includes all of the components of standard Weather Protection, plus the following:

Extended cabinet finishing with extra thick proprietary coatings

Special printed circuit board treatments

Use of corrosion-resistant hardware

Ultra Weather Protection is recommended for applications where loudspeakers will experience exposure to a salt air environment or chemicals, that have no sheltering from corrosive spray or UV exposure, and that cannot be covered or removed during their service life. Examples would include cruise ship exterior areas, ocean-side visitor attractions, swimming pool areas, and themed attractions with wind-carried water spray.

Ultra Weather Protection Version

Ultra Weather (UW) Protection is recommended for applications where loudspeakers will experience exposure to a salt air environment or chemicals, that have no sheltering from corrosive spray or UV exposure, and that cannot be covered or removed during their service life. Examples would include cruise ship exterior areas, ocean-side visitor attractions, swimming pool areas, and themed attractions with wind-carried water spray.

For installations in extremely harsh environments, Meyer Sound offers an IPX5-rated, Ultra Weather Protection version of the 900-LFC loudspeaker, which includes all of the components of standard Weather Protection, plus the following:

Extended cabinet finishing with extra thick proprietary coatings

Extra grille frame treatment with tighter weave mesh and acoustically transparent foam

Special printed circuit board treatments

Improved corrosion-resistant coatings and materials on select metallic components

Rigging changes for improved corrosion resistance

Rain hood splash guard for improved water resistance

Table 6 provides a list of the optional accessories and user-accessible hardware component differences for 900-LFC loudspeakers that ship from the factory as Ultra Weather Protection versions.

900-LFC Part/Accessory | UW 900-LFC Accessory/Part | Comment |

|---|---|---|

MG-LEOPARD/900-LFC Grid (PN 40.243.080.01) | MG-LEOPARD/900-LFC UW Grid, white (PN 40.243.180.05) or MG-LEOPARD/900-LFC UW Grid, black (PN 40.243.180.06) | See entries on “Grid to Loudspeaker Fasteners” and “Blanking Screws” in UW 900-LFC Accessory/Part column. |

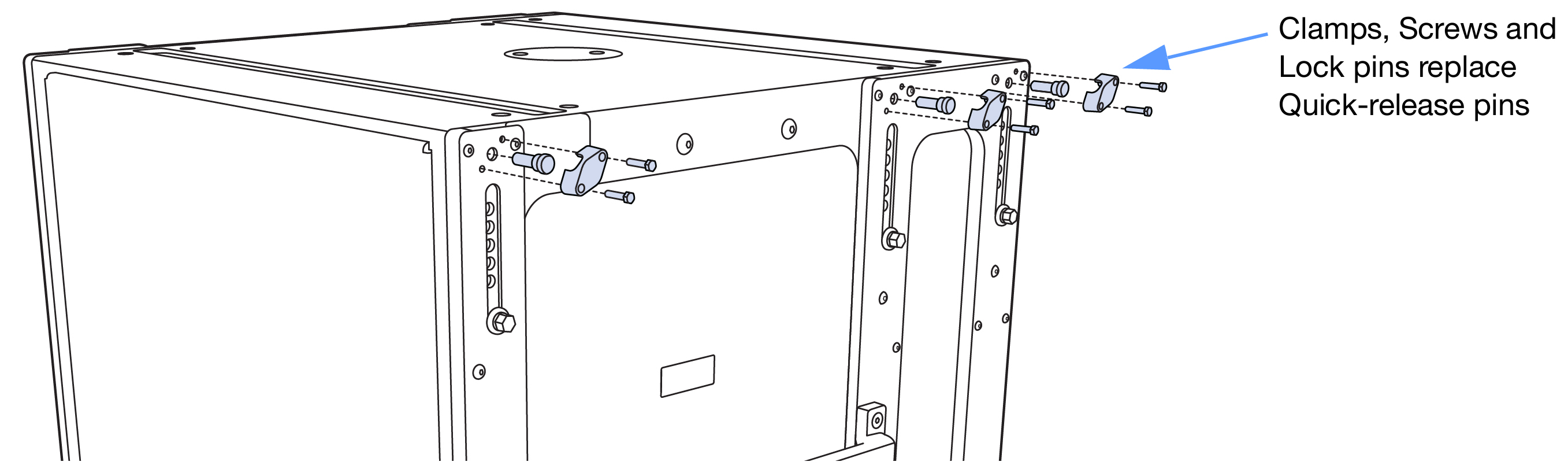

MG-LEOPARD/900-LFC Grid to Loudspeaker Quick-release pins (with lanyard) Red Button 5/16 in x 0.875 in with 6-inch lanyard (PN 134.025), qty 10 | MG-LEOPARD/900-LFC Grid to Loudspeaker Fasteners UW lock pin clamp, 5/16-inch with gasket, qty 4 (PN 45.010.506.05), white OR (PN 45.010.506.06), black Hex head screw with washer 8-32 x 3/4-inch, qty 12 (PN 45.010.934.05), white OR (PN 45.010.934.06), black CautionThese screws have a ! pre-applied thread-locking patch and cannot be reused. UW lock pin 5/16-in x 0.63-inch (PN 61.010.504.01), qty 4 | The clamps, screws, and lock pin replace the quick-release pins (with lanyard). Torque screws to 12 in-lb (1.36 N·m). |

Not applicable | MG-LEOPARD/900-LFC Blanking Screws 8-32 x 0.5-inch pan head Phillips stainless steel screw (PN 101.167), qty 12 | Two of these “blanking screws” are inserted around each grid pin hole location to prevent corrosion at unused pin locations (Figure 30). Those at locations where the speaker links will be attached must be removed before attaching a speaker to the grid. |

Rear cable ring and studs, qty 2 | Rigging Plate, stainless steel, qty 2 | The rear cable ring and studs (see Figure 15) are replaced with a stainless steel plate (see Figure 36). |

900-LFC Loudspeaker to Loudspeaker Quick-release pins Black Button 5/16 in x 0.63 in (PN 134.024), qty 8 | 900-LFC Loudspeaker to Loudspeaker Fasteners UW lock pin clamp, 5/16-inch with gasket, qty 8 (PN 45.010.506.05), white OR (PN 45.010.506.06), black Hex head screw with washer 8-32 x 3/4-inch, qty 20 (PN 45.010.934.05), white OR (PN 45.010.934.06), black UW lock pin 5/16-in x 0.63-inch (PN 61.010.504.01), qty 8 | The clamps, screws, and lock pin replace the quick-release pins (with lanyard). Torque screws to 12 in-lb (1.36 N·m) (See Figure 31). |

GROUNDSTACK DOWNTILT KIT: MG-LEOPARD/900-LFC (PN 40.243.0163.01) (Kit does not include quick-release pins because the angle feet are secured with the quick-release pins included with the grid.) | GROUNDSTACK DOWNTILT KIT: MG- LEOPARD/900-LFC UW, white (PN 40.243.163.05) or MG-LEOPARD/900-LFC UW, black (PN 40.243.163.06) | These UW kits include: LEOPARD/900-LFC Grid Tilt Assembly (PN 45.243.163.05 or 45.243.165.06), qty 2 LEOPARD UW/900-LFC UW Grid Links, (PN 61.243.191.05 OR PN 61.243.191.06), qty 4. Shoulder bolts 5/16x1-inch with 1/4-20 thread (PN 101.529), qty 10. Hex Nut, 1/4-20 thread, self-locking (PN 109.107), qty 10. The shoulder bolts and hex nuts replace the grid quick-release pins. |

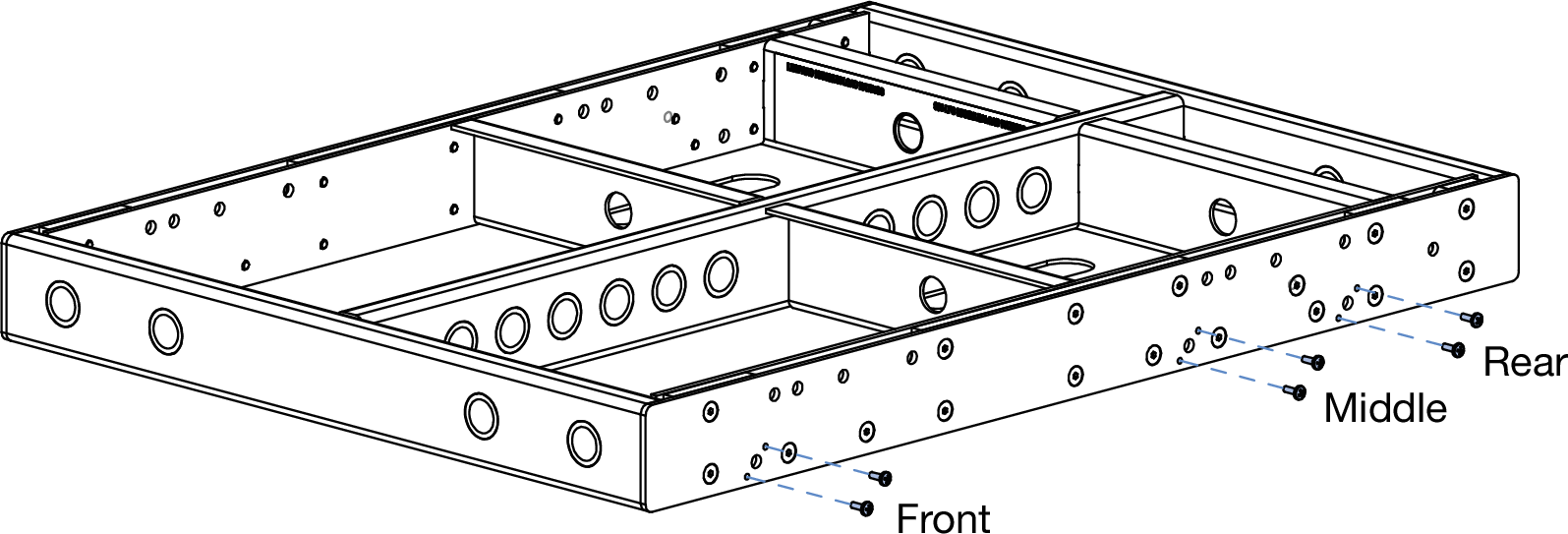

Blanking Screws (6 per side) to Prevent Corrosion at Unused Pin Locations for Ultra Weather Protection Grid

Ultra Weather Protection 900-LFC Loudspeaker Version has Clamps, Screws, and Lock pins that replace standard version quick-release pins

Note

For the 900-LFC UW loudspeaker version, the splay angles 0° and 1.25° are not available. Instead, an angle of 0.65° is provided.

Caution

For the 900-LFC UW loudspeaker version, the splay angles 0° and 1.25° are not available. Instead, an angle of 0.65° is provided.

Installation Practices

Meyer Sound assumes normal and accepted installation practices are used when installing Meyer Sound Loudspeakers outdoors. Deviation from such practices may cause weather protection to be ineffective and void the warranty for the loudspeaker.

Examples of unacceptable and acceptable installation practices include:

Loudspeakers installed outdoors should not face upward.

Loudspeakers with a rain hood should be installed in such a way that the rain hood opening is not facing any direction but down.

Meyer Sound-supplied rigging components should not be modified (for example, by drilling additional holes in a MUB for mounting to a wall). When an installer/integrator modifies a Meyer Sound-supplied rigging component to support their installation method, it is considered compromised and out of warranty.

All loudspeaker cabling must be installed with a "drip-loop" or equivalent method to ensure that rain/ water is NOT wicked toward the loudspeaker.

If in doubt about an installation method, contact Meyer Sound Technical Support for assistance.

Always discuss the environmental conditions of your Meyer Sound installation with your Sales Manager, and verify the availability of Weather Protection for your selected loudspeaker models. The Sales Manager, together with Technical Support, will verify the appropriate level of weather protection for the loudspeakers and related rigging hardware.

IP Ratings

IP stands for "Ingress Protection." The current format for expressing an IP rating is a 2-digit code. The first digit of an IP rating represents protection from solid objects. The second digit of an IP rating represents protection from water or moisture. The table below provides a chart of IP ratings and the corresponding definitions of the rating.

Note

IP ratings only apply to the "ENCLOSURE." A loudspeaker is considered an enclosure and as such we can apply an IP rating to it. Rigging hardware is not an enclosure and therefore IP ratings do not apply. Also, cable and cable-mount connectors used to connect to the loudspeaker are NOT part of the enclosure and therefore not part of the IP rating. Only the chassis-mounted part of the connector is considered part of the enclosure.

First Digit (Protection against solid objects) | Definition | Second Digit (Protection against liquids) | Definition |

|---|---|---|---|

X | Characteristic numeral is not required to be specified. | X | Characteristic numeral is not required to be specified. |

0 | No protection | 0 | No protection |

1 | Protected against solid objects over 50mm. | 1 | Protected against vertically falling drops of water. |

2 | Protected against solid objects over 12 mm. | 2 | Protected against direct sprays up to 15° from the vertical. |

3 | Protected against solid objects over 2.5mm. | 3 | Protected against direct sprays up to 60° from the vertical |

4 | Protected against solid objects over 1 mm. | 4 | Protected against direct sprays from all directions. Limited ingress permitted |

5 | Protected against dust. Limited ingress permitted. | 5 | Protected against low-pressure jets of water from all directions. Limited ingress permitted. |

6 | Totally protected against dust. | 6 | Protected against strong jets of water from all directions. Limited ingress permitted. |

7 | Protected against the effect of temporary immersion between 15cm and 1m. | ||

8 | Protected against the effect of long-term submersion of 1m or more. |