Operating Instructions — UPM-1P | 2P

Ultra-Compact Wide and Narrow Coverage Loudspeakers

Meyer Sound’s UPM-1P ultra-compact wide coverage and UPM-2P ultra-compact narrow coverage loudspeakers are self-powered professional sound reinforcement loudspeakers made for applications that require a small, inconspicuous system capable of high sound pressure levels.

UPM-1P ultra-compact wide coverage loudspeaker and the UPM-2P ultra-compact narrow coverage loudspeaker

In standalone under-balcony, front or side-fill applications, UPM-1P and UPM-2P loudspeakers can provide vocal range reinforcement as a small PA system, while a full-range system can be created with the addition of a separate sub-woofer. Other features include:

Extremely low distortion

Uniform directional control on both the horizontal and vertical axes

Dual 5-inch low-mid transducers

1-inch metal dome high-frequency driver on constant-directivity symmetrical horns

Two-channel power amplifier

Proprietary phase-corrected active processing circuitry

Both the UPM-1P and UPM-2P use a 1-inch metal dome tweeter on a symmetrical constant-directivity high-frequency horn. With its 45-degree beamwidth, the UPM-2P loudspeaker produces a narrow, symmetrical pattern for precise coverage control, while the UPM-1P loudspeaker offers a wider 100-degree symmetrical coverage pattern for broad listening areas.

Optimized Control Electronics

Like all Meyer Sound self-powered loudspeakers, the UPM-1P and UPM-2P exhibit superior performance across virtually all parameters. Because the amplifiers and control electronics are precisely optimized for each driver, the overall system is able to produce more power with flatter response and lower distortion. Self-powering also means simplifying installation by eliminating amplifier racks and external drive processing — allowing configuration of extensive distributed systems free from the signal losses imposed by long loudspeaker cable runs or 70/100-volt wiring schemes. The UPM-1P and UPM-2P loudspeakers also include a laser-trimmed differential input stage for high common mode rejection and can be equipped with Meyer Sound’s RMS™ remote monitoring system.

Three-Way System

Unlike similar conventional systems, the UPM-1P and UPM- 2P loudspeakers are three-way systems. In the pass band below 320 Hz, where greater power handling and cone area are needed, the 5-inch drivers are driven together in parallel. However, above 320 Hz a high-pass filter rolls off the signal going to one of the drivers, so only one of the two drivers reproduces the critical mid frequencies close to the crossover frequency. Since power requirements are drastically lower in this region, there is no loss in response. and a remarkably uniform response at all frequencies along all axes — horizontal, vertical, and diagonal.

Note

In conventional two-way designs, both low-mid drivers reproduce the same information throughout their operating range. At low frequencies, this is not an issue, since the wavelengths (500 Hz, about two feet) are longer than the distance between the center points of the two cones. But at around 1 kHz, problems arise in the off-axis vertical response of the system. As the wavelengths of critical mid frequencies approach the distance between loudspeaker centers, significant comb filtering effects appear. These “holes” can be quite severe. In applications where such a loudspeaker is mounted vertically and the audience area is contained entirely within a 50-degree vertical arc, sharp off-axis attenuation may not be detrimental. However, if you flip the cabinet on its side to use it as an under-balcony loudspeaker, you will experience serious difficulties.

The UPM-1P and UPM-2P loudspeakers provide a more elegant solution, with an active crossover distributing the signal between the low- and high-frequency sections, and a simpler 2-way passive crossover that is employed to implement the single-point midrange solution. In addition, a sophisticated phase correction circuit in the active electronics compensates for phase shift in the passive network. The result is a significantly better system impulse response, and better imaging when UPM-1P and UPM-2P loudspeakers are used in stereo or multi-channel applications.

Applications

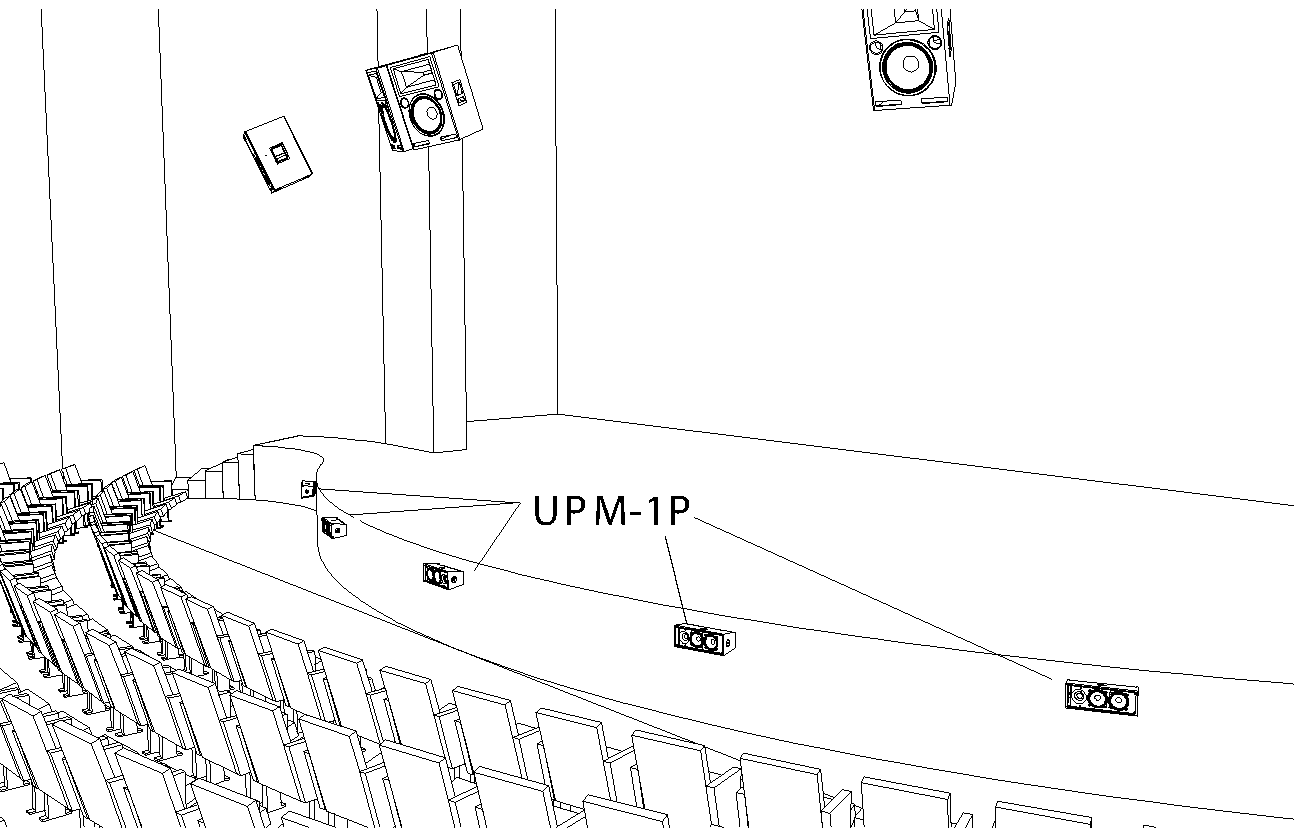

The UPM-1P and UPM-2P loudspeakers are designed to be used in a wide variety of applications in sound reinforcement, as well as music playback and monitoring. In theatre sound design, the UPM-1P and UPM-2P loudspeakers may be used as fill as well as a standalone effects loudspeaker system for surround, onstage effects, and anywhere a compact device is required. For example, equally spacing UPM-1P loudspeakers across the downstage edge or under a balcony, as shown in the figure below, offers very accurate audio reproduction for theatre design.

UPM-1Ps arranged across a downstage edge

The UPM-1P loudspeaker’s wide 100-degree pattern is designed to keep sound from being too localized, allowing for more even SPL distribution across seats near the stage or any other areas the loudspeaker is intended to cover. For more focused directional control, the UPM-2P’s 45-degree beamwidth produces a narrow, symmetrical pattern to accommodate ultra-precise design requirements.

The 123 dB peak SPL of the UPM-1P and UPM-2P loudspeakers makes them an excellent choice for use as fill-in sports facilities. They can be used in stadiums and arenas as upper-level delay loudspeakers or under upper-level overhangs, as well as in suites and box seats that fall out of the main system’s direct path.

The UPM-1P and UPM-2P loudspeakers also work as stand-alone PA systems for accurate spoken word reproduction and, with the addition of a companion subwoofer, a small music reinforcement system.

In addition, because of the flatter phase and frequency response of Meyer Sound UltraSeries loudspeakers, the UPM-1P and UPM-2P loudspeakers can be ideal for high-definition music monitoring when used with a subwoofer. The wide-coverage UPM-1P loudspeaker provides better imaging in stereo and 5.1 playback applications, while the narrower UPM-2P gives you the flexibility to localize coverage in the near field.

Available QuickFly® rigging accessories— including a mounting yoke (MYA-UPM), stand adapter (MSA-UPM), and U-bracket (MUB-UPM)— attach easily to the UPM-1P and UPM-2P allowing them to be mounted or flown, either as a single cabinet or in arrays. The optional RMS remote monitoring system module allows comprehensive monitoring of all key system parameters on a remote RMS host PC.

Power Requirements

Self-powered and compact, UPM-1P and UPM-2P loudspeakers combine advanced technology with equally advanced power capabilities. Understanding power distribution, voltage, and current requirements, as well as electrical safety issues, is critical to the safe operation of the loudspeakers.

AC Power

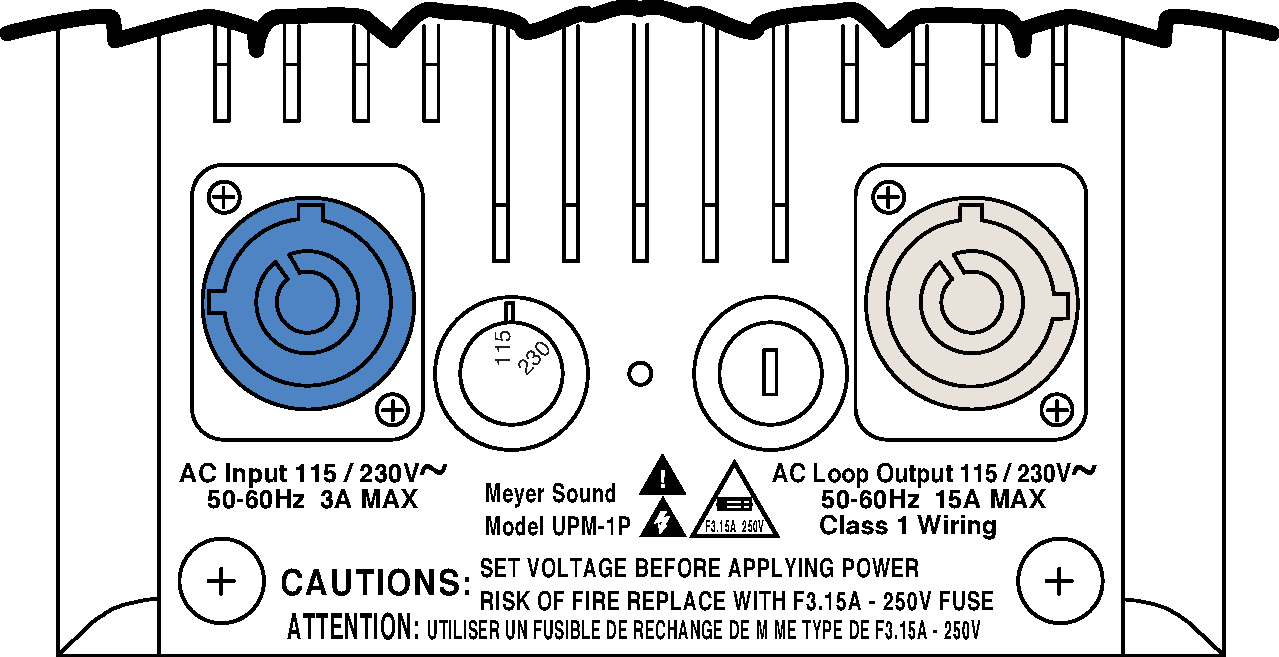

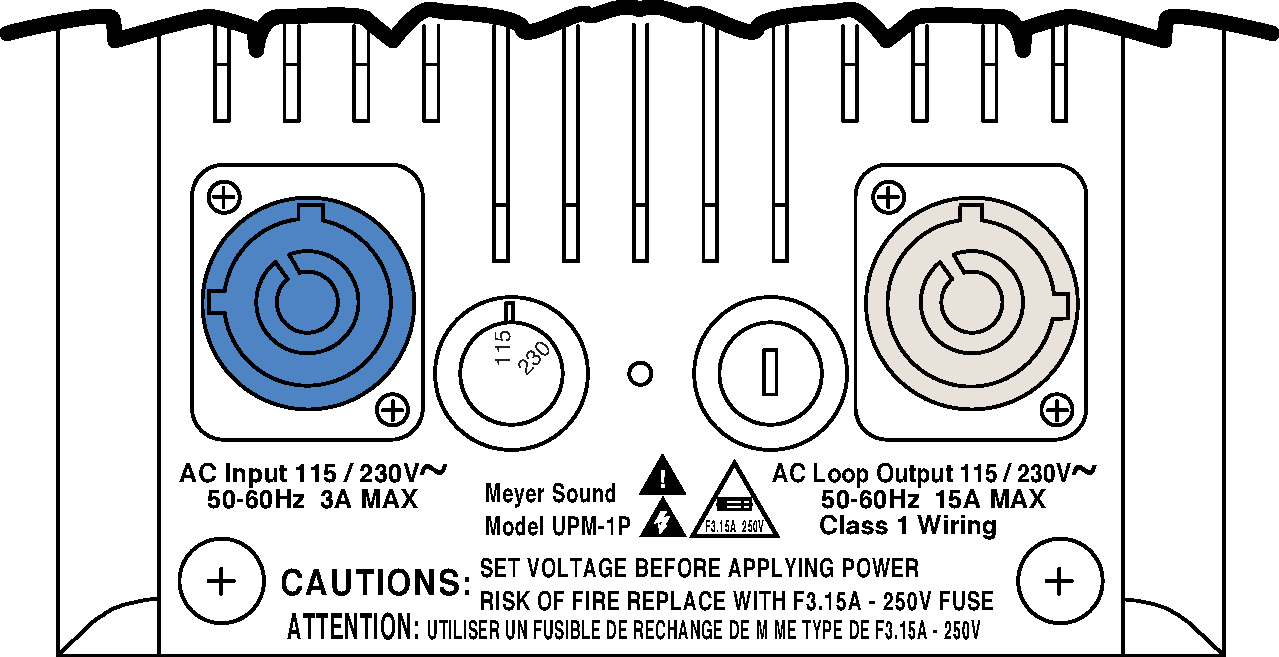

UPM-1P and UPM-2P loudspeakers use a PowerCon® three-pole AC mains system with locking connectors to prevent accidental disconnection. They may also be daisy-chained by using the grey connector (Figure 1.1) to loop units together. The blue connector serves as the power input; to loop additional units, simply attach a cable from the grey connector of the first loudspeaker system to the blue connector of the second, and so on. One cablemount loop-out grey connector is shipped with the unit.

|

You can daisy-chain UPM-1P and UPM-2P loudspeakers using the grey connector

Caution

Do not loop more than four UPM-1P or UPM-2P loudspeakers from the loop out connector when driven at 115 volts and not more than eight when driven at 230 volts.

Ensure that you select the correct power plug for the AC power in the area in which you use your loudspeaker.

The power supply suppresses high voltage transients up to several kilovolts and also filters EMI (radio frequencies and noise present) on the incoming AC voltage. The UPM- 1P can withstand continuous voltages up to 264 volts and allow any combination of voltage to GND (that is neutral-line-ground or line-line-ground).

Caution

Continuous voltages higher than 265 volts may damage your UPM-1P or UPM-2P loudspeaker.

Voltage Selection

Two versions of both the UPM-1P and UPM-2P loudspeakers are available: a switchable 115/230-volt and a non-switchable 100-volt version. The non-switchable 100-volt version will operate properly when receiving between 87 and 113 volts; the switchable version requires you to check the voltage switch and set it to either 115 or 230 volts. When set to 115 volts, the UPM-1P and UPM-2P will operate properly when the AC remains within the range of 105 to 130 volts. If set to 230 volts, the unit operates safely and without audio discontinuity within the range of 210 to 264 volts. Operating outside these ranges or with the voltage switch set improperly could damage the unit.

Caution

To avoid damage to the unit, check the AC voltage selector switch (shown in the figure below) on the user panel before plugging in the unit and applying power. Set the switch to local AC voltage. Always unplug the power cord before changing the voltage selector switch.

|

Rear panel AC inlet and voltage selector switch

After applying AC power, the system is muted while the circuitry charges up and stabilizes. After two seconds, the following occurs:

The main power supply slowly ramps on.

The green On/Temp LED on the user panel lights up, indicating that the system is enabled and ready to pass audio signals.

Caution

If the On/Temp LED does not illuminate or the system does not respond to audio input after 10 seconds, remove AC power immediately. Verify that the voltage is within the proper range. If the problem persists, please contact Meyer Sound or an authorized service center.

If voltage drops below the low boundary of its safe operating range (brownout), the UPM-1P or UPM-2P loudspeakers use stored energy to continue functioning briefly, and shut down only if voltage does not rise above the low boundary before storage circuits are depleted.

How long the loudspeaker will continue to function during brownout depends upon the amount of voltage drop and the audio source level during the drop.

If the voltage increases above the upper boundary of either range, the power supply may be damaged.

Note

It is recommended that the supply be operated in its rated voltage window at least a few volts away from the turn on/off points. This ensures that that AC voltage variations from the service entry – or peak voltage drops due to cable runs – do not cause the amplifier to cycle on and off or cause damage to the power supply.

Current Requirements

The UPM-1P and UPM-2P loudspeakers require approximately 3 amps rms max at 115 volts AC for proper operation. This allows up to five loudspeakers to be powered from one 15-amp breaker.

The UPM-1P and UPM-2P loudspeakers present a dynamic load to the AC mains, which causes the amount of current to fluctuate between quiet and loud operating levels. Since different cables and circuit breakers heat up at varying rates, it is essential to understand the types of current ratings and how they correspond to circuit breaker and cable specifications.

The maximum long-term continuous current is the maximum rms current during a period of at least ten seconds. It is used to calculate the temperature increase in cables, in order to select a cable size and gauge that conforms to electrical code standards. It is also used to select the rating for slow-reacting thermal breakers.

The burst current is the maximum rms current during a period of approximately one second, used to select the rating of most magnetic breakers and to calculate the peak voltage drop in long AC cables according to the formula:

V pk (drop)= I pk x R (cable total)

The ultimate short-term peak current is used to select the rating of magnetic breakers.

Use the Current Ratings for UPM-1P and UPM-2P table below as a guide when selecting cable gauge size and circuit breaker ratings for your operating voltage.

Current Draw | 115 V AC | 230 V AC | 100 V AC |

|---|---|---|---|

Max. long-term continuous | 1 A rms | 0.5 A rms | 1.2 A rms |

Burst current | 1.3 A rms | 0.65 A rms | 1.5 A rms |

Ultimate short-term peak | 2.9 A pk | 2 A pk | 3.3 A pk |

Idle current | 0.13 A rms | 0.065 A rms | 0.15 A rms |

Note

For best performance, the AC cable voltage drop should not exceed 10 volts, or 10 percent at 115 volts and 5 percent at 230 volts. Make sure that even with the AC voltage drop the AC voltage always stays in the operating window.

The minimum electrical service amperage required by UPM-1P and UPM-2P systems is the sum of each loudspeaker’s maximum continuous rms current. An additional 30 percent above the minimum amperage is recommended to prevent peak voltage drops at the service entry.

Caution

In the unlikely event that the fuse trips, always replace a fuse with the same rating and type of fuse. The UPM-1P and UPM-2P loudspeakers use a quick-acting 3.15-amp current, 250 volts low breaking capacity fuse.

Power Connector Wiring

The UPM-1P and UPM-2P loudspeakers require a grounded outlet. It is very important that the system be properly grounded in order to operate safely and properly. Use the AC cable wiring diagram shown below to create international or special-purpose power connectors.

AC cable color code

If the colors referred to in the figure above don’t correspond to the terminals in your plug, use the following guidelines:

Connect the blue wire to the terminal marked with an N or colored black.

Connect the brown wire to the terminal marked with an L or colored red.

Connect the green and yellow wire to the terminal marked with an E, G, or the protective earth ground symbol:

.

.

Electrical Safety Issues

Pay close attention to these important electrical and safety issues.

Caution

The UPM-1P and UPM-2P require a ground connection. Always use a grounded outlet and plug. Do not use a ground-lifting adapter or cut the AC cable ground pin.

Caution

Keep all liquids away from the UPM-1P and UPM-2P to avoid hazards from electrical shock.

Do not operate the unit with worn or frayed cables; replace them immediately.

Amplification and Audio

The UPM-1P and UPM-2P loudspeakers use sophisticated amplification and protection circuitry to produce consistent and predictable results in any system design. This chapter will help you understand and harness the power of the UPM-1P and UPM-2P amplifier and audio systems.

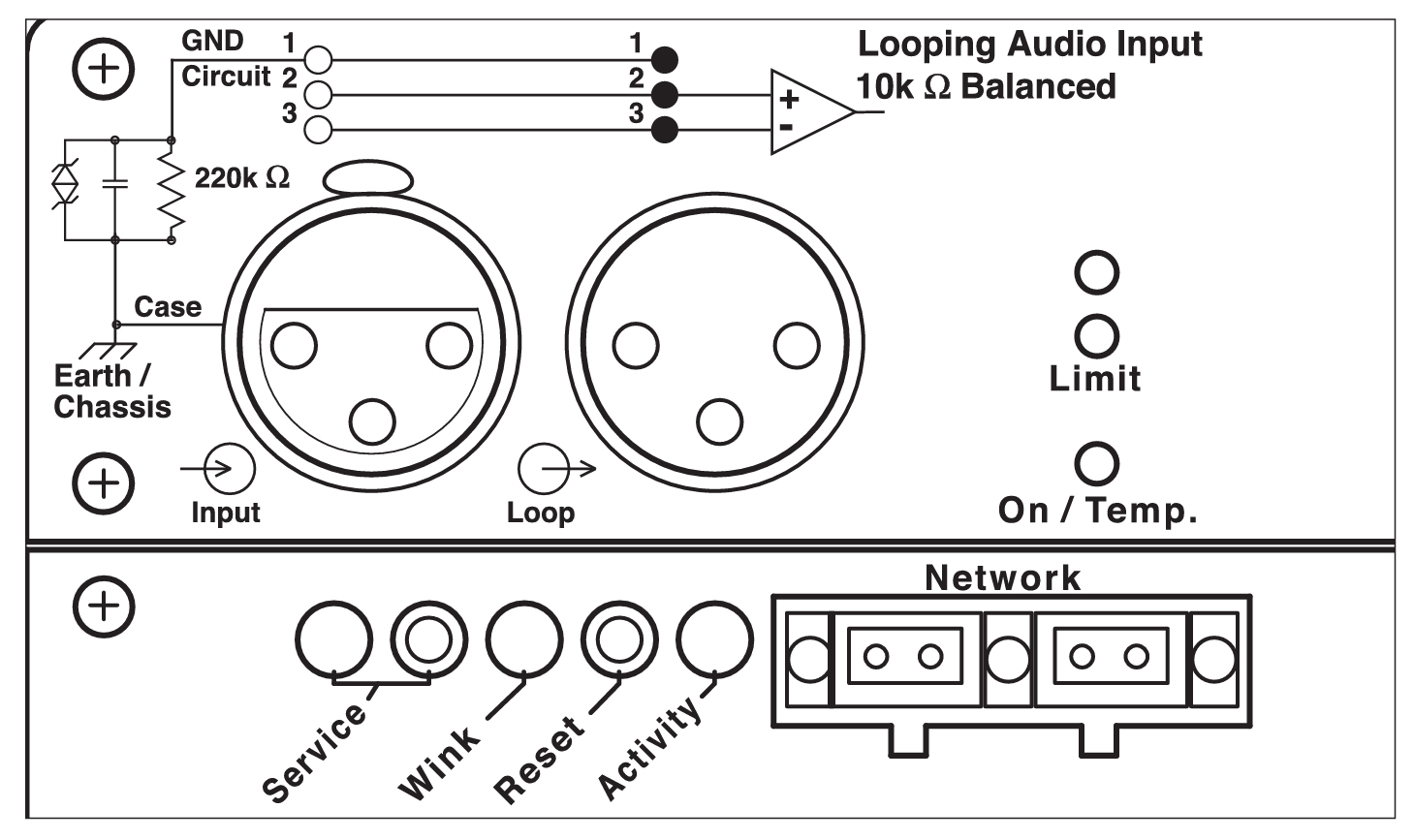

The user panel of the loudspeaker, as shown in the figure below, provides two slots for modules. The top slot contains the audio input module. The optional RMS communications module sits in the bottom slot if installed; a blank plate covers the bottom slot if RMS is not installed.

The user panel of the UPM-1P with standard looping audio input module and optional RMS

Note

See RMS Remote Monitoring System (optional), for more information on using RMS with the UPM-1P and UPM-2P loudspeakers.

Audio Input

UPM-1P and UPM-2P loudspeakers use a balanced, female XLR connector for the audio input module in the loudspeaker, and a male XLR loop connector to interconnect multiple cabinets. The loop connector, wired in parallel to the audio input, transmits the input signal if the loudspeaker is turned off for any reason.

The audio input presents a 10 kOhm balanced input impedance to a three-pin XLR connector with the following connectors:

Pin 1 — 220 kOhm to chassis and earth ground (ESD clamped)

Pin 2 — Signal ( + )

Pin 3 — Signal ( - )

Case — Earth (AC) ground and chassis

Note

Ensure that all cabling carrying signal to multiple loudspeakers is wired correctly (Pin 1 to Pin 1, Pin 2 to Pin 2, and so on), to prevent the polarity from being reversed. If one or more loudspeakers in a system has reversed polarity, this can cause severe degradation in frequency response and coverage.

Caution

Shorting an input connector pin to the case can form a ground loop and cause hum.

Input Module Options

There are two interchangeable audio input modules with and without controls for different applications.

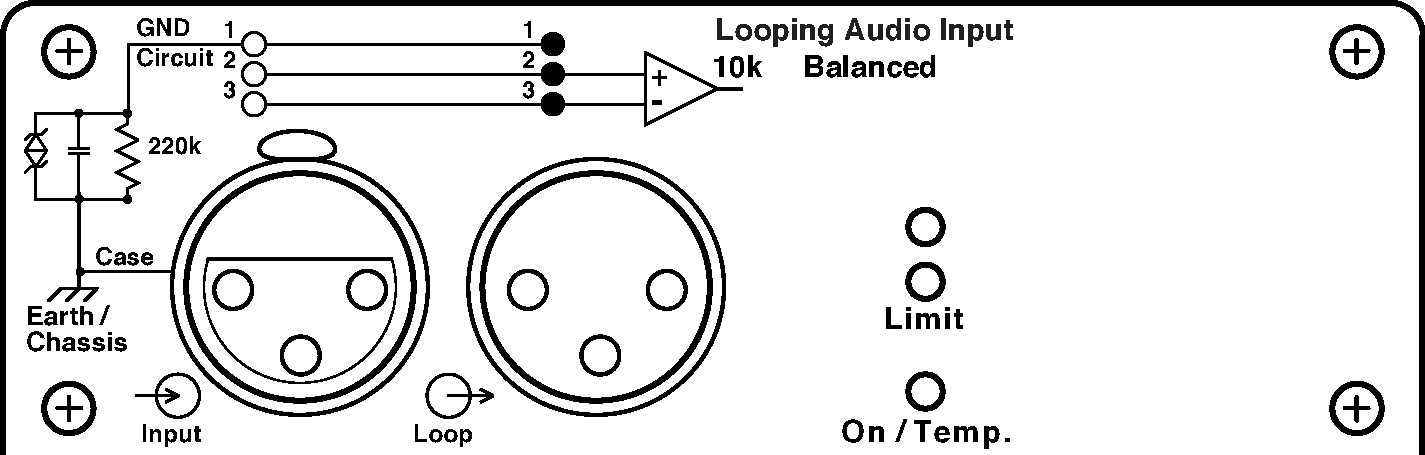

Looping Audio Input Module

All UPM-1P and UPM-2P loudspeakers are equipped standard with the looping audio input module, as shown in the figure below. Pins 2 and 3 carry the input as a differential signal; pin 2 is hot relative to pin 3, resulting in a positive pressure wave when a positive signal is applied to pin 2. This input module has a balanced, female XLR audio input connector and a male XLR loop out connector.

The looping audio input module

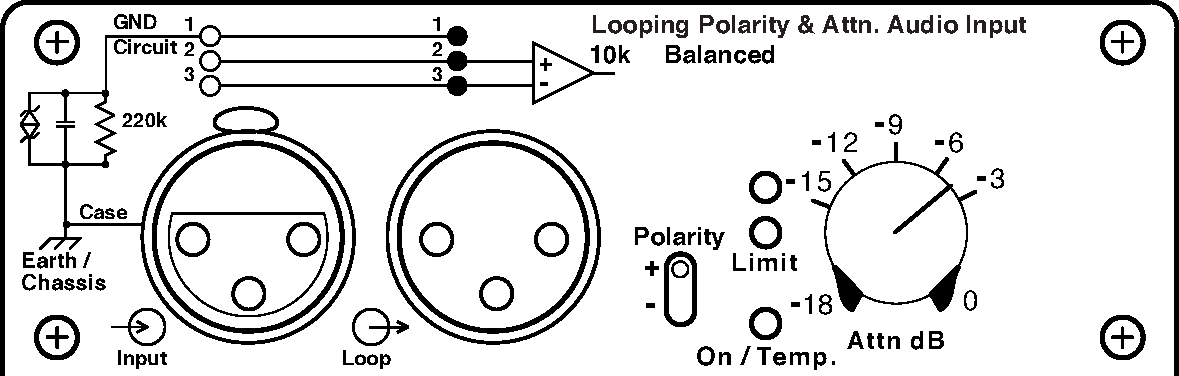

Looping, Polarity and Attenuating Audio Input Module

The looping, polarity and attenuating audio input module, shown in the figure below, has a balanced, female XLR audio input connector, a male XLR loop connector, an input polarity switch, and a level attenuator. The input polarity switch offers a convenient method of reversing the polarity of the loudspeaker. The loop out remains unchanged.

The looping, polarity and attenuating audio input module

When the input polarity switch is in the up ( + ) position, pin 2 is hot. When the switch is down ( - ), pin 3 is hot relative to pin 2, resulting in a positive pressure wave when a positive signal is applied to pin 3. The level attenuator operates between 0 dB (no level attenuation) when turned all the way to the right and –18 dB when turned all the way to the left.

Note

In both modules, Pin 1 is connected to earth through a 220 kOhm, 1000 pF, 15-volt clamp network. This ingenious circuit provides virtual ground lift at audio frequencies, while allowing unwanted signals to bleed to ground. Use standard audio cables with XLR connectors for balanced signal sources with all three pins connected on both ends. Telescopic grounding is not recommended.

Regardless of the input module type, audio signals can be daisy-chained using the loop output connector on the user panel. A single source can drive multiple loudspeakers with a paralleled input loop, creating an unbuffered hard-wired loop connection. If driving multiple loudspeakers in a system, make certain that the source device can drive the total load impedance presented by the paralleled input circuit of the system. The audio source must be capable of providing a minimum of 20 dB volts (10 volts rms into 600 ohms) to produce the maximum peak SPL over the operating bandwidth of the loudspeaker.

To avoid distortion from the source, make sure the source equipment provides an adequate drive circuit design for the total paralleled load impedance presented by the system. The input impedance for a single loudspeaker is 10 kOhms. If n represents the number of loudspeakers in a system, paralleling the inputs of n loudspeakers will produce a balanced input load of 10 kOhms divided by n.

Note

Most source equipment is safe for driving loads no smaller than 10 times the source’s output impedance.

For example, cascading an array of 10 loudspeakers produces an input impedance of 1000 ohms (10 kOhms divided by 10). The source equipment should have an output impedance of 100 ohms or less. This is also true when connecting UPM-1P or UPM-2P loudspeakers in parallel (loop out) with other self-powered Meyer Sound loudspeakers and subwoofers.

Tip

If the loudspeaker produces hissing and popping or similar noises, disconnect the audio cable from the loudspeaker. If the noise stops, then most likely the problem is not with the loudspeaker. Check the audio cable, source, and AC power.

Amplification and Limiting

The low and high-frequency drivers in the UPM-1P and UPM-2P loudspeakers are powered by a two-channel proprietary Meyer Sound amplifier utilizing complementary MOSFET output stages. The amplifier processes the audio through the use of electronic crossover, phase and frequency response correction filters as well as driver protection circuitry. Each channel has peak and rms limiters that prevent driver over-excursion and regulate the temperature of the voice coil. Limiter activity for the high and low channels is indicated by two yellow limit LEDs on the rear panel (the high-frequency limit LED is on top and the low-frequency limit LED is on bottom).

Caution

Although the UPM-1P and UPM-2P use the same amplifier/heatsink module, their internal control boards are different. In order to maintain factory acoustical specifications and driver protection (as well as keep from voiding the factory warranty), never interchange the amplifiers used in the UPM-1P and UPM-2P. If you need to replace a UPM-1P or UPM-2P amplifier and/or control board, please contact Meyer Sound.

The UPM-1P and UPM-2P loudspeakers perform within their acoustical specifications and operate at a normal temperature if the limit LEDs are on for no longer than two seconds, and off for at least one second. If either LED remains on for longer than three seconds, that channel incurs these consequences:

Increasing the input level will not increase the volume.

The system distorts due to clipping and nonlinear driver operation.

Unequal limiting between the low and high-frequency drivers alters the frequency response.

The lifespan of the drivers is reduced because they are subjected to excessive heat.

Limiters protect the system under overload conditions and exhibit smooth sonic characteristics, but it is recommended that you do not drive the loudspeaker into continuous limiting.

Caution

The limit LEDs indicate when the safe power level is exceeded. If the loudspeakers used in the system begin to limit before reaching the required SPL, consider adding more loudspeakers to satisfy the SPL requirements without exposing the drivers to excessive heat and/ or excursion.

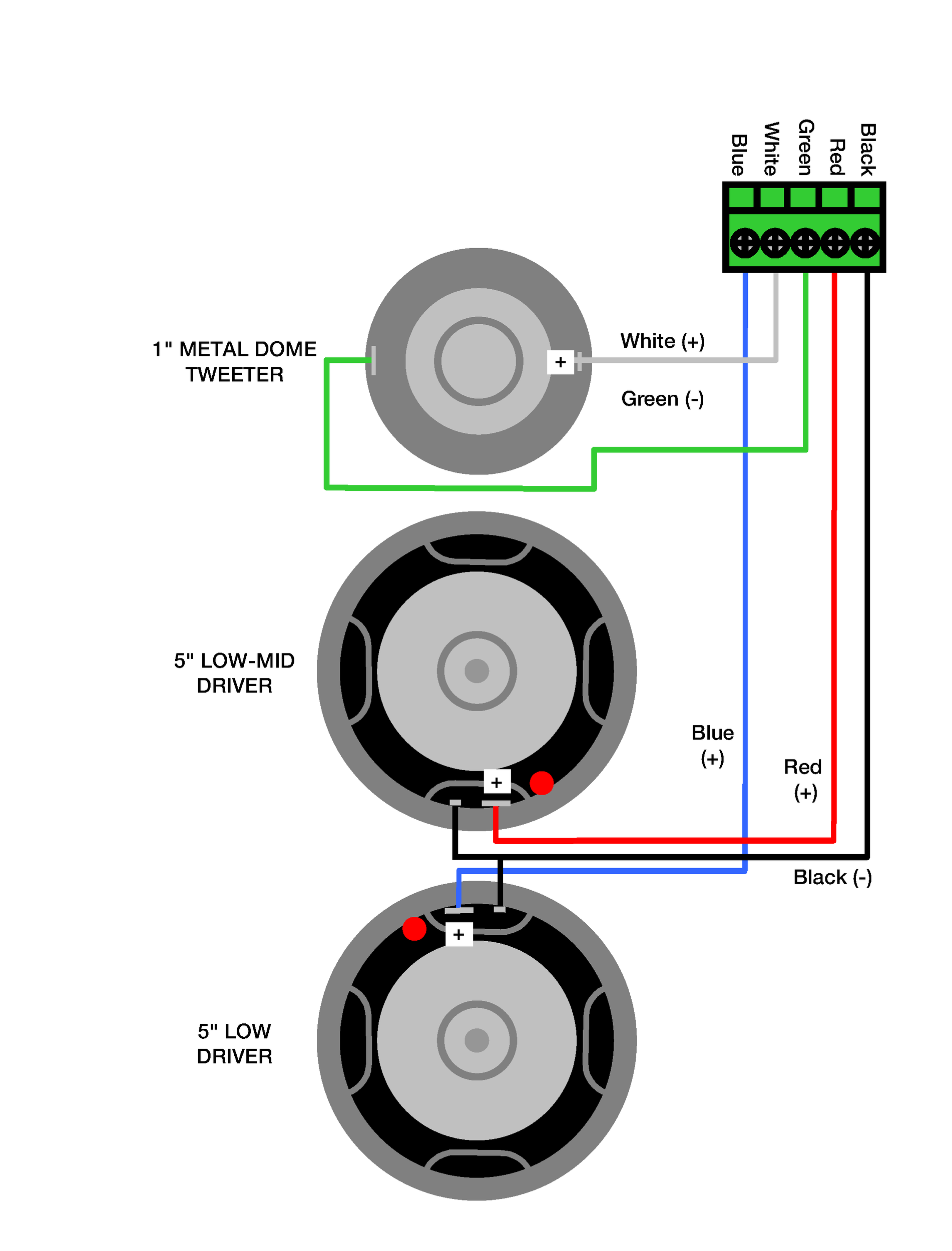

Driver Interconnections

The two 5-inch, low-frequency drivers are powered by one channel of the amplifier. The single 1-inch metal dome high-frequency driver is powered by the other channel. The figure below shows how the UPM-1P and UPM-2P drivers are connected to the amplifier.

UPM-1P and UPM-2P driver connections to the amplifier

Caution

All Meyer Sound loudspeakers are shipped with the drivers in correct alignment. However, if a driver needs to be replaced, make sure the replacement is reinstalled with the correct polarity. Incorrect driver polarity impairs the system performance and may damage the drivers.

RMS Remote Monitoring System (optional)

An optional RMS communication module can be installed in the UPM-1P and UPM-2P loudspeakers' lower module slot.

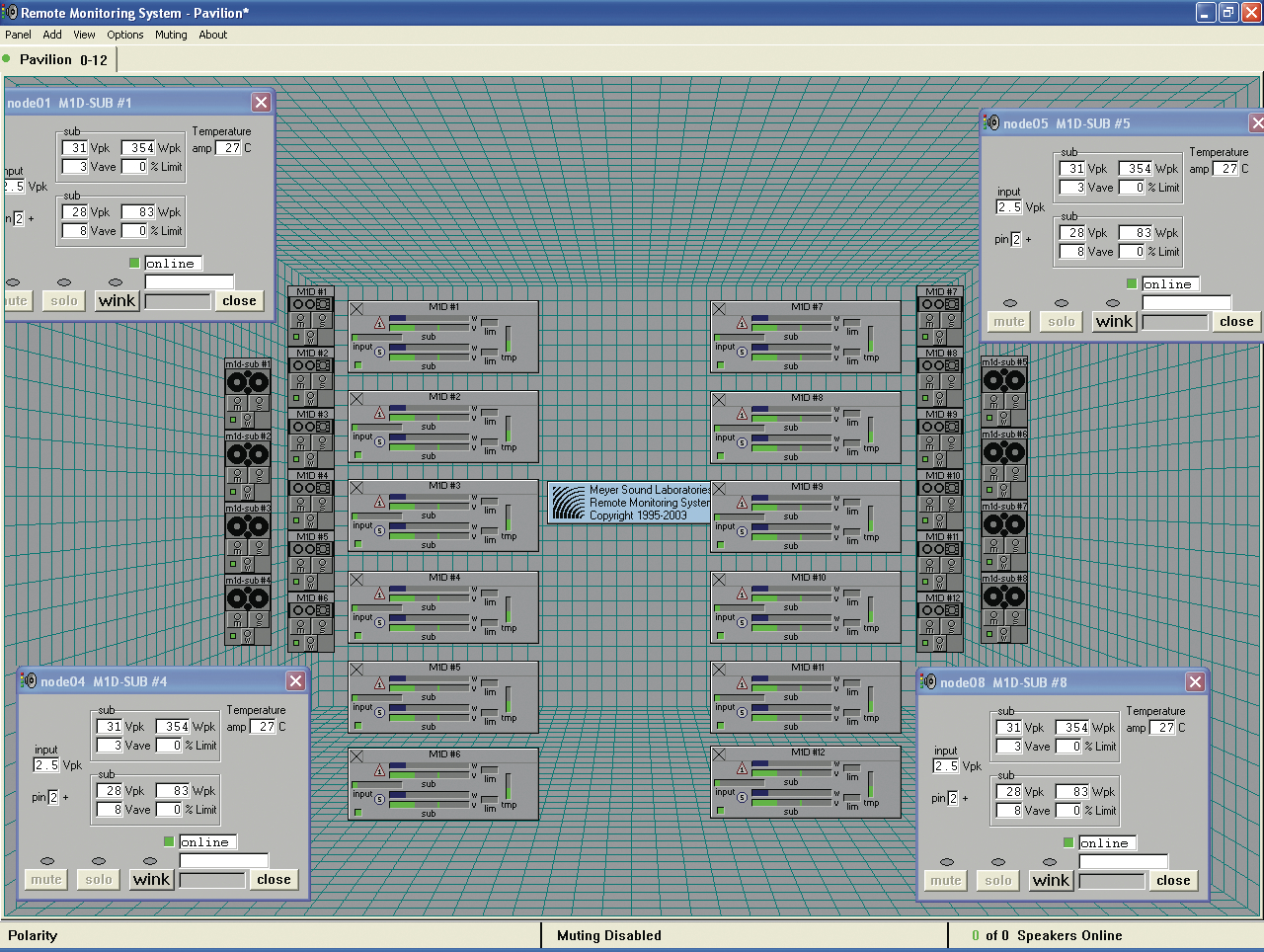

RMS is a real-time networked monitoring system that connects Meyer Sound self-powered loudspeakers with a Windows-based PC at the sound mix position or other desired remote location. Optional RMS software delivers extensive status and system performance data directly to you from every installed loudspeaker.

RMS allows you to monitor amplifier voltages, limiting activity, power output, temperature, fan and driver status, warning alerts, and other key data for up to 62 loudspeakers without a network repeater; data is updated two to five times per second.

Note

Optional Loudspeaker Mute and Solo functions, helpful for acoustic setup or troubleshooting, are also available. A jumper must be installed in the RMS communication module in order to enable Mute and/or Solo functionality; the software also needs to be enabled for these functions. When fitted with an RMS communication module, the loudspeaker is shipped with these functions disabled. Once the RMS jumper(s) are installed, muting can still be disabled to eliminate any chance of an operator error (a muting error, for example) during a performance. Both functions can be controlled by software commands. Also, note that RMS does not control AC power.

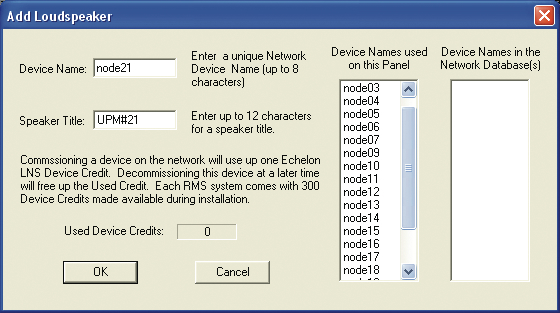

As shown in the figure below, loudspeakers are identified on the network by Node Names assigned during a one-time “commission” into the RMS database that resides on the host computer (as a part of the software).

Commissioning a loudspeaker using RMS

This information is permanently stored on each RMS communication module and in the RMS database unless you modify it. Speaker Titles can be modified at any time, allowing you to customize how you view the data.

In addition, any loudspeaker can be physically identified from RMS software by activating the Wink function – a Wink LED will turn on the RMS communication board that corresponds to its Node Name.

A loudspeaker is identified using the RMS software by activating the “service” function; an icon will show up on the RMS screen corresponding to its Node Name, as shown in the figure below. This makes verifying Speaker Titles and speaker field labels easy, using the Wink or Service Button commands.

RMS loudspeaker icons

Note

If the loudspeaker’s amplifier heatsink temperature exceeds 75° C (167° F), the loudspeaker's user panel On/Temp LED will turn red, while the loudspeaker icon in the RMS host software will respond by displaying yellow — indicating that the loudspeaker is running hot, but still within safe operating limits. If the LED in the RMS host software changes to red, then the UPM- 1P/UPM-2P is operating above its 100º C (212° F) maximum safe operating temperature. Check to ensure that the cabinet is properly ventilated and/ or decrease the loudspeaker’s audio output signal immediately.

Understanding the RMS User Panel

The RMS section of the user panel has three LEDs and two buttons, as shown in the figure below.

RMS section of the user panel

The following sections describe their functions.

Service LED (Red)

When blinking once every two seconds, the Service LED indicates that the network hardware is operational, but the loudspeaker is not installed (commissioned) on the network. When a loudspeaker has been installed on the network the Service LED will be unlit and the Activity LED will flash continuously.

Note

When continuously lit, the Service LED indicates that the loudspeaker has had a local RMS hardware failure. In this case, the RMS communication module may be damaged and you should contact Meyer Sound Technical Support.

Service Button

Pressing the Service button will display an indicator on the corresponding loudspeaker display icon on the RMS screen. Press and hold both the Service and the Reset buttons to decommission the communications module will from the network. The red Service LED will blink.

Wink LED (green)

When lit, the Wink LED indicates that an ID signal has been sent from the host station computer to the loudspeaker. This is accomplished using the Wink button on the loudspeaker Icon, Meter or Text views in the RMS monitoring program.

Reset Button

Pressing the Reset button will cause the firmware code within the RMS card to reboot. However, the commissioning state of the communications module will not change (this is stored in flash memory). When used in combination with the Service button, the communications module will be decommissioned from the network and the red Service LED will blink.

Activity LED (Green)

When the loudspeaker has been commissioned the Activity LED will flash continuously. When the Activity LED is unlit (and the red LED is blinking) the loudspeaker has not been installed on the network.

Note

The LEDs and buttons on the RMS section of the user panel are used exclusively by RMS, and have no effect on the acoustical and/or electrical activity of the loudspeaker itself – unless Mute or Solo is enabled at the module and from the RMS software.

User Interface

The optional RMS software features an intuitive, graphical user interface. As mentioned earlier, each loudspeaker appears on your computer monitor as a “view” in the form of a status icon, bar graph meter, or text meter (numerical values), depending on your preferences.

Each view contains loudspeaker identification information and data from the amplifier, controller, drivers and power supply of that particular unit. System status conditions cause changes in icon and bar graph indicators, alerting the operator to faults or excessive levels. The views are moveable and are typically arranged on the screen to reflect the physical layout of the loudspeakers. You can design a screen “panel” of icons or meters, as shown in the figure below, and save it on your hard disk, with the panel conveniently named for a unique arrangement or performance.

Sample RMS display panel

If the loudspeaker installation pattern changes completely, a new screen panel can be built. If a different subset of already installed loudspeakers will be used for a subsequent show, only selected loudspeakers need to appear on the monitoring screen for that performance.

Using Subwoofers with the UPM-1P and UPM-2P

UPM-1P and UPM-2P loudspeakers can be deployed in combination with Meyer Sound self-powered USW-1P compact and UMS-1P ultra-compact subwoofers. These subwoofers are capable of producing very low frequencies and extending overall system response appreciably and increasing the acoustic power of a system in the lowest frequencies. The UMS-1P and USW-1P extend system frequency response down to 29 Hz and 30 Hz, respectively.

In addition, the use of high-pass filters to drive a UPM-1P or UPM-2P system with subwoofers flattens overall frequency response and slightly increases UPM-1P or UPM-2P headroom in the lowest end of their usable spectrum.

The ideal ratio of UPM-1P or UPM-2P loudspeakers to subwoofers depends on the configuration of the system, the application, and the frequency content of the signal being reproduced. For most applications, a ratio of two UPM-1P or UPM-2P loudspeakers for each UMS-1P subwoofer and four UPM-1P or UPM-2P loudspeakers for each USW-1P subwoofer yields good results in frequency response and headroom.

Note

The limit LEDs indicate when the safe power level is exceeded. If the subwoofers used in the system begin to limit before reaching the required SPL at low frequencies, consider adding more subwoofers to satisfy the SPL requirements without exposing the drivers to excessive heat and/or excursion.

Daisy-chained

When UPM-1P or UPM-2P loudspeakers and subwoofers are daisy-chained using the loop feature on the user panel, the result will be a fairly flat frequency response. However, the response will show a rise in the 60 to 200 Hz range where the loudspeakers’ response overlaps at a ratio of two UPM-1P or UPM-2P loudspeakers to each subwoofer.

Make sure the polarity of the UPM-1P or UPM-2P loudspeakers and the subwoofers are identical. If the UPM-1P/UPM-2P and the USW-1P or UMS-1P are both fitted with the standard looping module, there is no polarity switch; all loudspeakers in the system are set to pin 2+. However, if they are fitted with looping, polarity and attenuation audio input modules, make sure both are set to the same polarity.

If the UPM-1P/UPM-2P loudspeakers and USW-1P or UMS-1P subwoofers are separated by a greater distance — or delay must be used between them — a measurement system such as the SIM audio analyzer should be used to determine the correct delay and polarity.

Caution

Make sure that the source equipment can drive the total load of the paralleled system. See Audio Input for more information.

Note

When a UPM-1P or UPM-2P loudspeaker and a subwoofer are used in their full-range configuration (e.g., looped audio or the same audio feed), their polarities should be kept the same if they are co-planar or near to each other. If they are separated by a greater distance — or delay must be used between them — a measurement system such as Meyer Sound’s SIM® audio analyzer should be used to determine the correct delay and polarity.

Adding a Line Driver

Driving a UPM-1P or UPM-2P loudspeaker system and subwoofers with the same signal from different outputs using a line driver allows adjustments to the gain and polarity of each sub-system. This could be used effectively to compensate for the ratio of loudspeakers or acoustical conditions. If gains are adjusted to the same level, the combined response is identical to a daisy-chain configuration with a rise in level in the overlapping range.

Note

When driving UPM-1P and/or UPM-2P loudspeakers from the Mid-Hi output of the LD-1A, LD-2 or LD-3 line driver, with USW-1P or UMS-1P subwoofers driven from the subwoofer output in their full-range configuration, their polarities should be kept the same if they are co-planar or near each other.

If the UPM-1P/UPM-2P loudspeakers and USW-1P or UMS-1P subwoofers are separated by a greater distance — or delay must be used between them — a measurement system such as the SIM audio analyzer should be used to determine the correct delay and polarity.

Engaging the Lo-Cut Filter

Using the LD-1A, LD-2 or LD-3 Lo-Cut filter (160 Hz position on the LD-3) with a system comprising UPM-1P or UPM-2P loudspeakers and subwoofers in close proximity and co-planar will produce a very flat frequency response with a minimal area of overlap. The UPM-1P or UPM-2P loudspeakers in the system receive their signal following a high-pass filter, while the subwoofers apply their normal internal crossover frequencies to a full range signal. To achieve this flat response, the subwoofers need to have their polarity reversed.

Tip

The flatness of the response is dependent on proximity to boundary surfaces.

While the change of polarity with respect to a daisy-chained configuration is needed due to the phase shift caused by the high-pass filter at overlapping frequencies, placing subwoofers more than 4 feet apart from UPM-1P or UPM- 2P loudspeakers may require reversing the polarities once again to compensate for the delay propagation.

Note

When driving UPM-1P or UPM-2P loudspeakers from the Mid-Hi output of the LD-1A, LD-2 or LD-3 line driver — with the Lo-Cut filter engaged (160 Hz position), and USW-1P or UMS-1P subwoofers in their full-range configuration — their polarities should be reversed if they are co-planar or near each other. The simplest way to achieve this is by engaging the “reverse polarity” switch on the sub output of the line driver.

If your UPM-1P or UPM-2P loudspeakers and UMS-1P/ USW-1P subwoofers are separated by a greater distance — or delay must be used between them — a measurement system such as the SIM audio analyzer should be used to determine the correct delay and polarity.

Digital Signal Processors

Full-range signals may be applied to Meyer Sound’s self-powered loudspeakers because they have built-in active crossover circuits; external crossovers and digital signal processors (DSP) are optional and should be used very carefully as phase shifts can cause destructive cancellations.

If a DSP is used, the UPM-1P or UPM-2P loudspeakers and subwoofers should be fed from the DSP in order to keep their delay time the same and avoid any phase shift differences between the UPM-1P or UPM-2P loudspeakers and the subwoofers. In addition, it is good practice to verify that the delay time between channels is correct: Some DSPs may develop channel-to-channel delay errors when the DSP is near maximum throughput.

In no case should a filter higher than 2nd order be used. The additional phase shift introduced deteriorates the impulse response and higher roll-off does not improve crossover interaction. In fact, it is highly recommended that the crossover/filter is set to emulate the low-cut LD-1A, LD-2, and LD-3 (160 Hz position) characteristics themselves, as shown in the table below.

Type | Order | Pole Frequency | Q |

|---|---|---|---|

High Pass | 2nd (-12dB/oct) | 162 Hz | 0.82* |

*If the DSP does not have variable Q for high-pass filters, the filter should be set to “Butterworth” (Q ≈ .7).

If the loudspeakers are going to be driven directly from DSP, verify that the outputs of the processor have the driving capabilities to drive the total load presented by the loudspeakers connected to it.

Note

When precise system design, subwoofer integration, DSP and delay systems, and compensation for acoustical conditions all come into play, measurement and correction tools are a must. Meyer Sound’s SIM audio analyzer; LD-1A, LD-2, and LD-3 line drivers; and the CP-10 parametric equalizer are highly recommended.

System Design and Integration Tools

MAPP System Design Tool

The MAPP System Design Tool is a powerful, cross-platform application for accurately predicting the coverage pattern, frequency response, phase response, impulse response, and SPL capability of individual or arrayed Meyer Sound loudspeakers.

MAPP System Design Tool

Whether planning for fixed installations or for tours with multiple venues, use MAPP to accurately predict the appropriate loudspeaker deployment for each job, complete with coverage data, system delay and equalization settings, rigging information, and detailed design illustrations. MAPP’s accurate, high-resolution predictions ensure that systems will perform as intended, thereby eliminating unexpected coverage problems and minimizing onsite adjustments.

The key to the accuracy of MAPP’s predictions is MeyerSound’s exhaustive database of loudspeaker measurements. Performance predictions for each loudspeaker are based on 3-dimensional, 65,000+ 1/48th-octave-band measurements taken in the MeyerSound anechoic chamber. The extraordinary consistency between Meyer Sound loudspeakers guarantees that predictions from MAPP will closely match their actual performance.

MAPP software allows for configuration of MeyerSound loudspeaker systems and definition of the environment in which they operate, including air temperature, pressure, humidity, and the location of prediction surfaces. Importing both CAD (.DXF) and Sketchup (.SKP) files containing detailed venue information to act as an anchor model to the prediction surfaces and a visual aid to facilitate prediction data interpretation is also possible.

Tip

See meyersound.com for support and more information about MAPP.

MAPP Capabilities

With MAPP, you can:

Simulate different loudspeaker configurations to refine system designs and determine the best coverage for intended audience areas

Model loudspeaker interactions to locate constructive and destructive interferences so that loudspeakers can be re-aimed and repositioned as necessary

Place microphones anywhere in the Model View space and predict loudspeaker frequency response, phase response, and sound pressure levels at each microphone position

Determine delay settings for fill loudspeakers using the Inverse Fast Fourier Transform and phase response feature

Preview the results of signal processing to determine optimum settings for the best system response

Automatically calculate load information for arrays to determine necessary minimum rigging capacity, front-to-back weight distribution, and center of gravity location

Generate and export system images and system PDF reports for client presentations

Synchronize GALAXY processor output channel settings in real-time with virtual or real GALAXY units, allowing in-the-field changes to be predicted during system alignments

Galileo GALAXY Network Platform

The Galileo GALAXY Network Platform is a sophisticated loudspeaker management tool for controlling all MeyerSound speaker types. The GALAXY loudspeaker processor extends a high level of audio control in driving and aligning loudspeaker systems with multiple zones. It provides a powerful tool set for corrective equalization (EQ) and creative fine-tuning for a full range of applications from touring to cinema.

Users can readily program the GALAXY processor using Compass software running on a host computer or via the Compass Go application for the iPad. Connecting MAPP to the GALAXY processor will also allow the user to push output channel settings created in MAPP as a starting point. Compass Control Software includes custom-designed settings for each family of speakers, as well as to integrate families together. For example, the Product Integration feature matches the phase characteristics between Meyer speaker families to ensure the most coherent summation.

Processing tools for inputs and outputs include delay, parametric EQ and U-Shaping EQ. Output processing also includes polarity reversal, Low-Mid Beam Control (LMBC), atmospheric correction, and All Pass filters.

The built-in summing and delay matrices allow a user to easily assign gain and delay values, respectively, at each cross point. This capability greatly facilitates using one loudspeaker to satisfy multiple purposes.

Front panel controls let a user intuitively and quickly operate a GALAXY processor without a computer during live use.

The GALAXY 408, GALAXY 816 and GALAXY 816-AES3 processor versions have the same audio processing capability with different I/O. See www.meyersound.com to locate their datasheets for more information.

QuickFly Rigging

The UPM-1P and UPM-2P can utilize components from Meyer Sound’s QuickFly system — a range of rugged, reliable, and deceptively simple rigging and mounting components. QuickFly facilitates placing loudspeakers in single units, hanging or attached to a surface, for a variety of applications.

Caution

All Meyer Sound products must be used in accordance with local, state, federal, and industry regulations. It is the owner’s and/or user’s responsibility to evaluate the reliability of any rigging method for their application. Rigging should be carried out only by experienced professionals.

Always use properly rated rigging hardware.

It is important to inspect rigging hardware regularly and replace worn or damaged components immediately.

Each loudspeaker includes three rigging plates, situated on the top, bottom, and on one side of the cabinet. There are two types of interchangeable rigging hardware, each fastened by three Phillips screws:

3/8"-16 nut plates

M10 x 1.5 metric nut plates

Caution

Units are rated for the weight of one cabinet only.

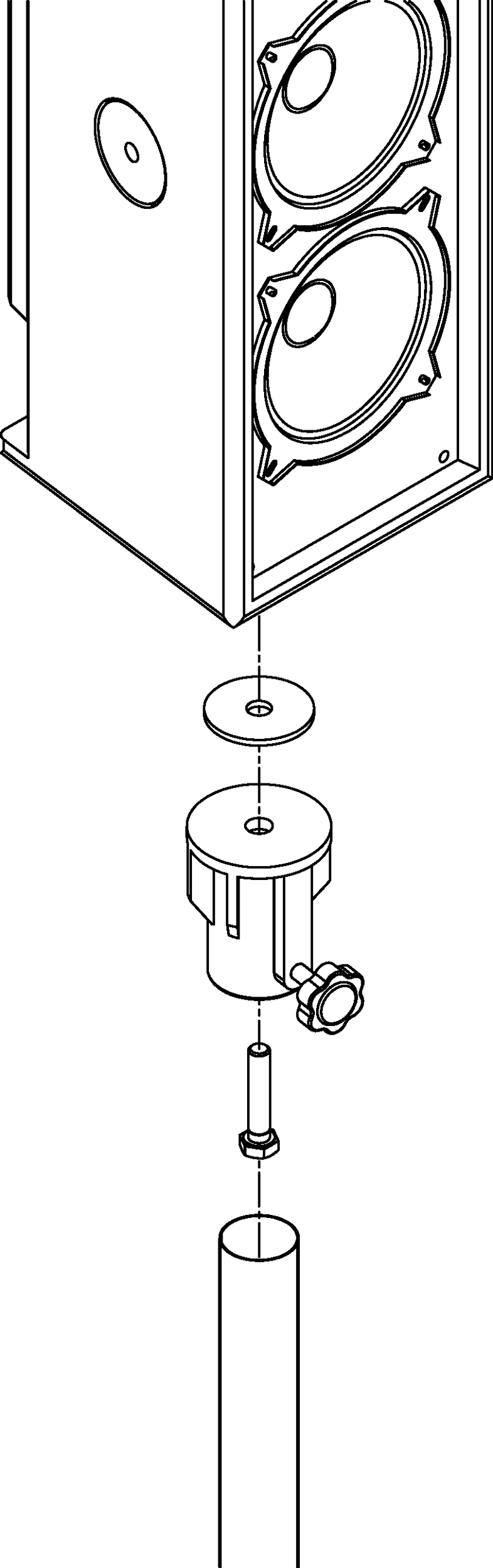

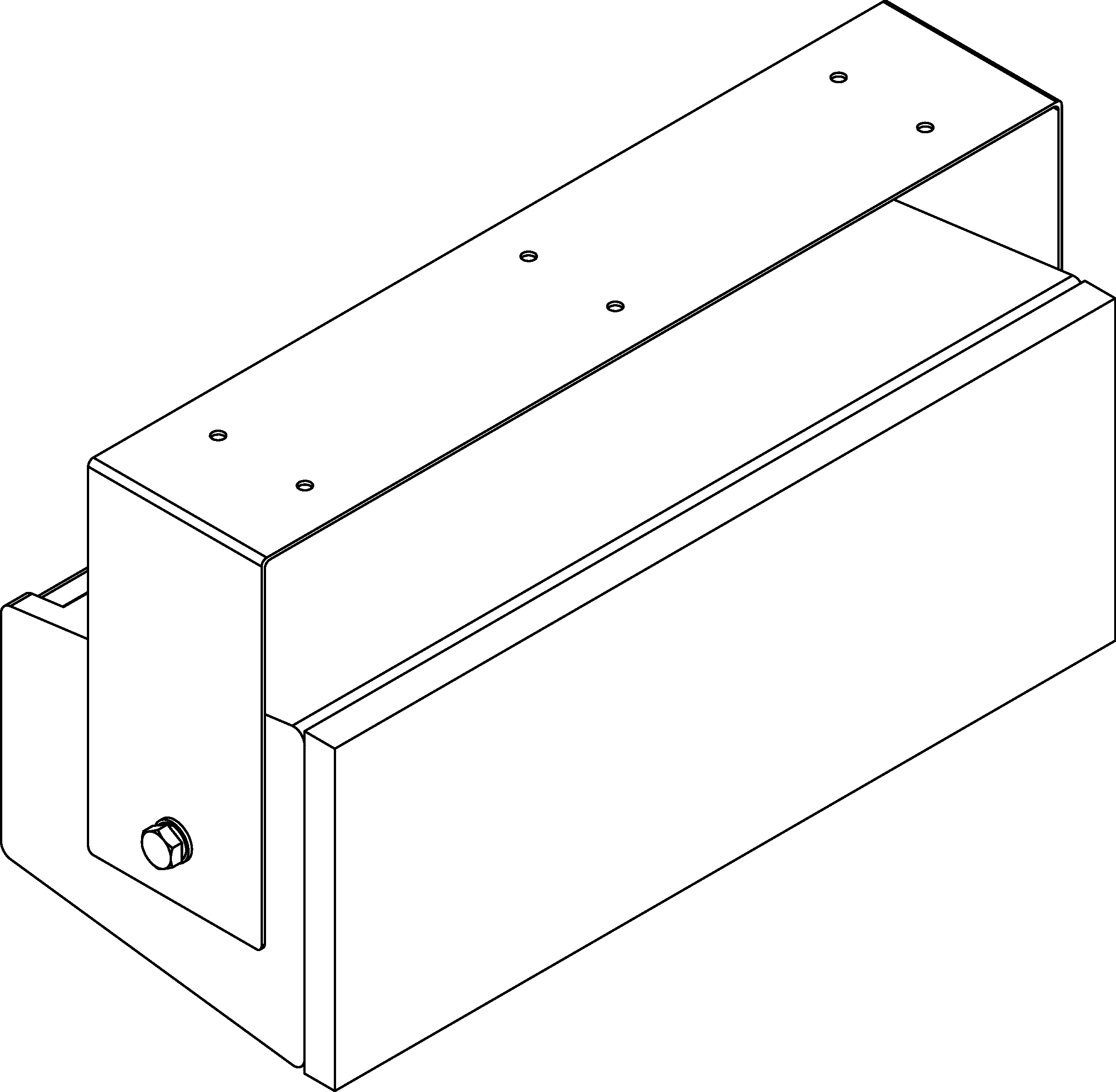

Stand mounting the UPM-1P and UPM-2P Loudspeakers

You can mount the UPM-1P or UPM-2P loudspeaker on a stand using the MSA-UPM stand adapter, as shown in the figure below, along with a third-party loudspeaker stand such as those made by Ultimate Support Systems (www.ultimatesupport.com).

The MSA-UPM kit includes 3/8"-16 and M10 hardware. To secure the adapter, attach the adhesive-backed cork washer to the stand and secure the stand to the loudspeaker using the bolt and washer, as shown in the figure below.

MSA-UPM Stand Adapter

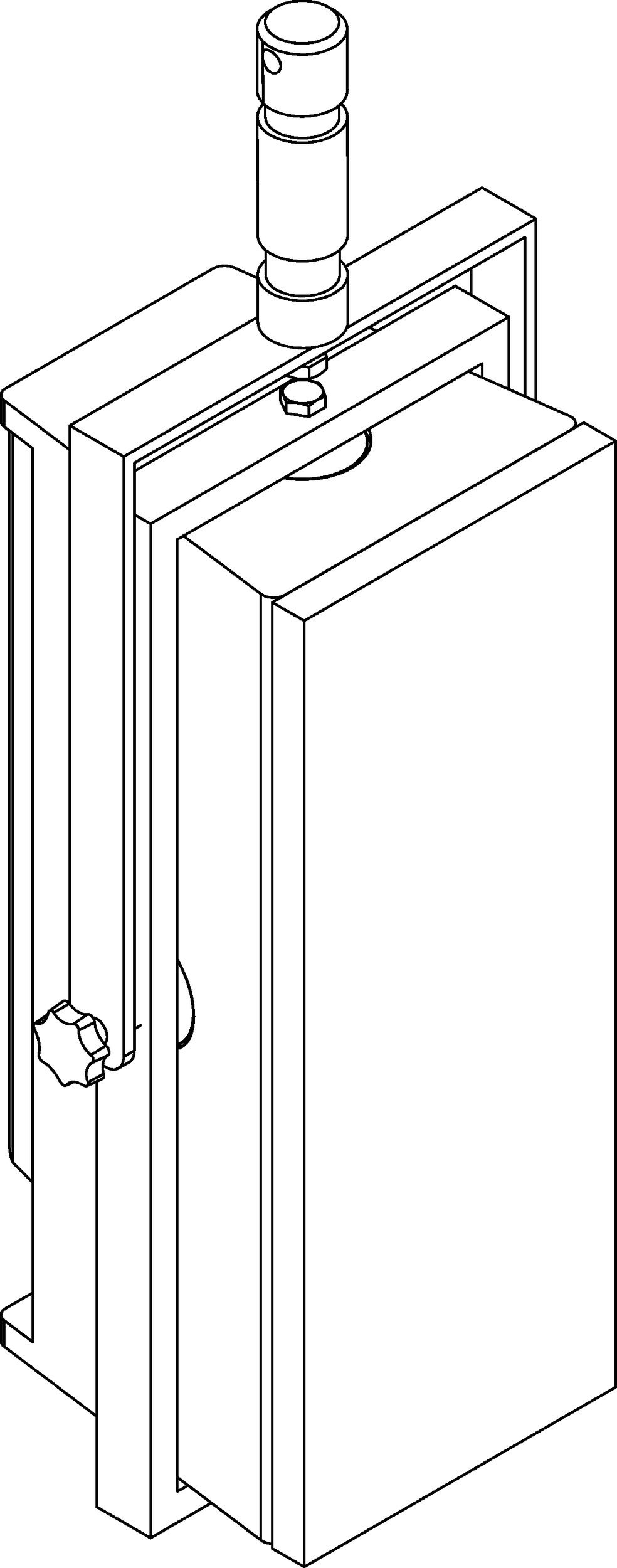

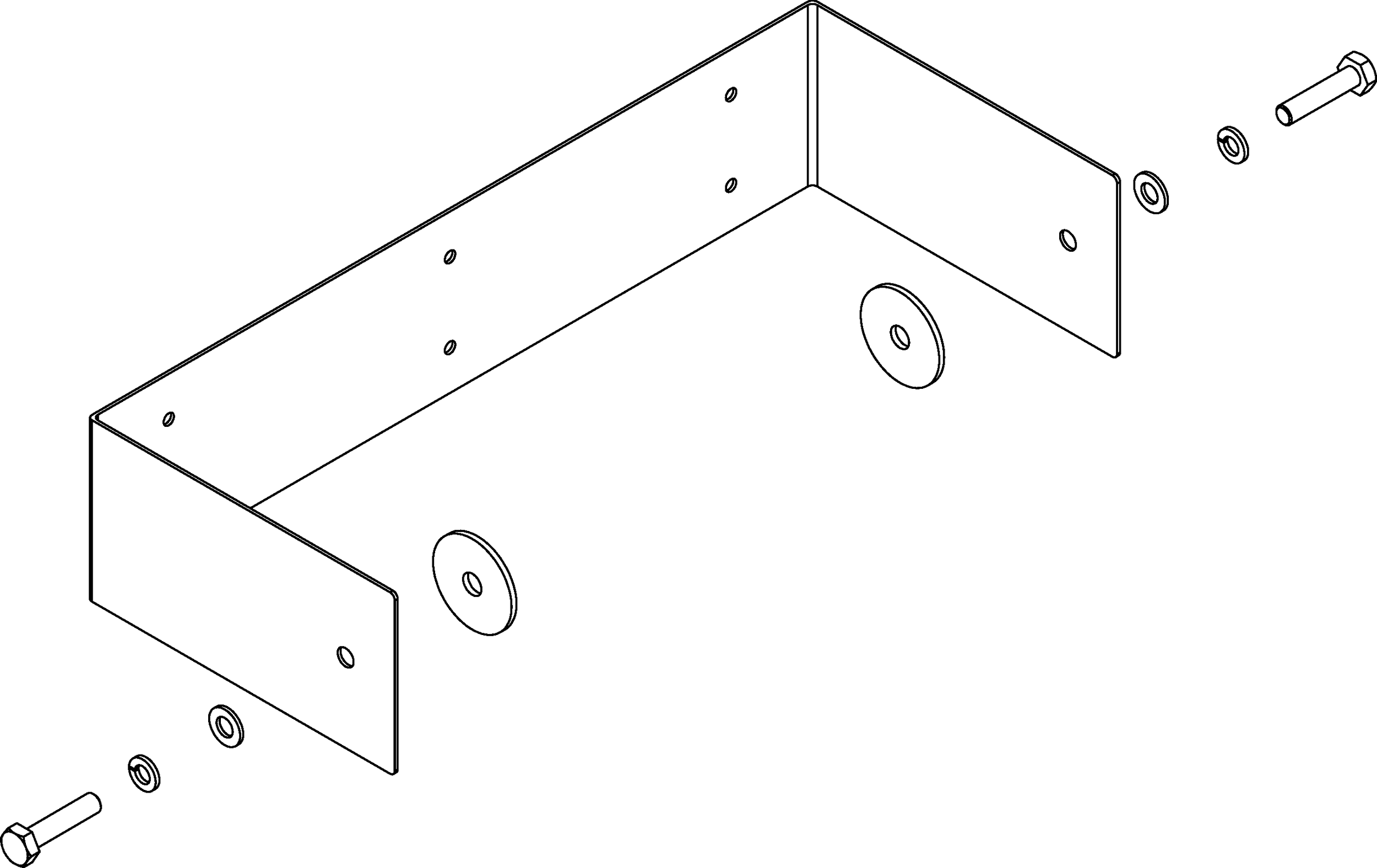

MYA-UPM Mounting Yoke Assembly

This cradle-style mounting yoke, shown in the figure below, suspends a single UPM-1P or UPM-2P loudspeaker and allows a wide range of horizontal and vertical adjustment. The yoke attaches to the top and bottom nut plates. The mounting yoke kit includes 3/8"-16 and M10 hardware.

The MYA-UPM is used to suspend a single UPM-1P or UPM-2P cabinet

Caution

To secure the loudspeaker to the yoke, tighten the bottom bolt first and then the top. Do not over-torque the top and bottom bolts, as this may damage the cabinet.

A hanging clamp (“C” or “G” type) and a steel safety cable are required to enable the yoke to be used (not supplied as a part of the yoke assembly kit).

Using the MUB-UPM U-bracket

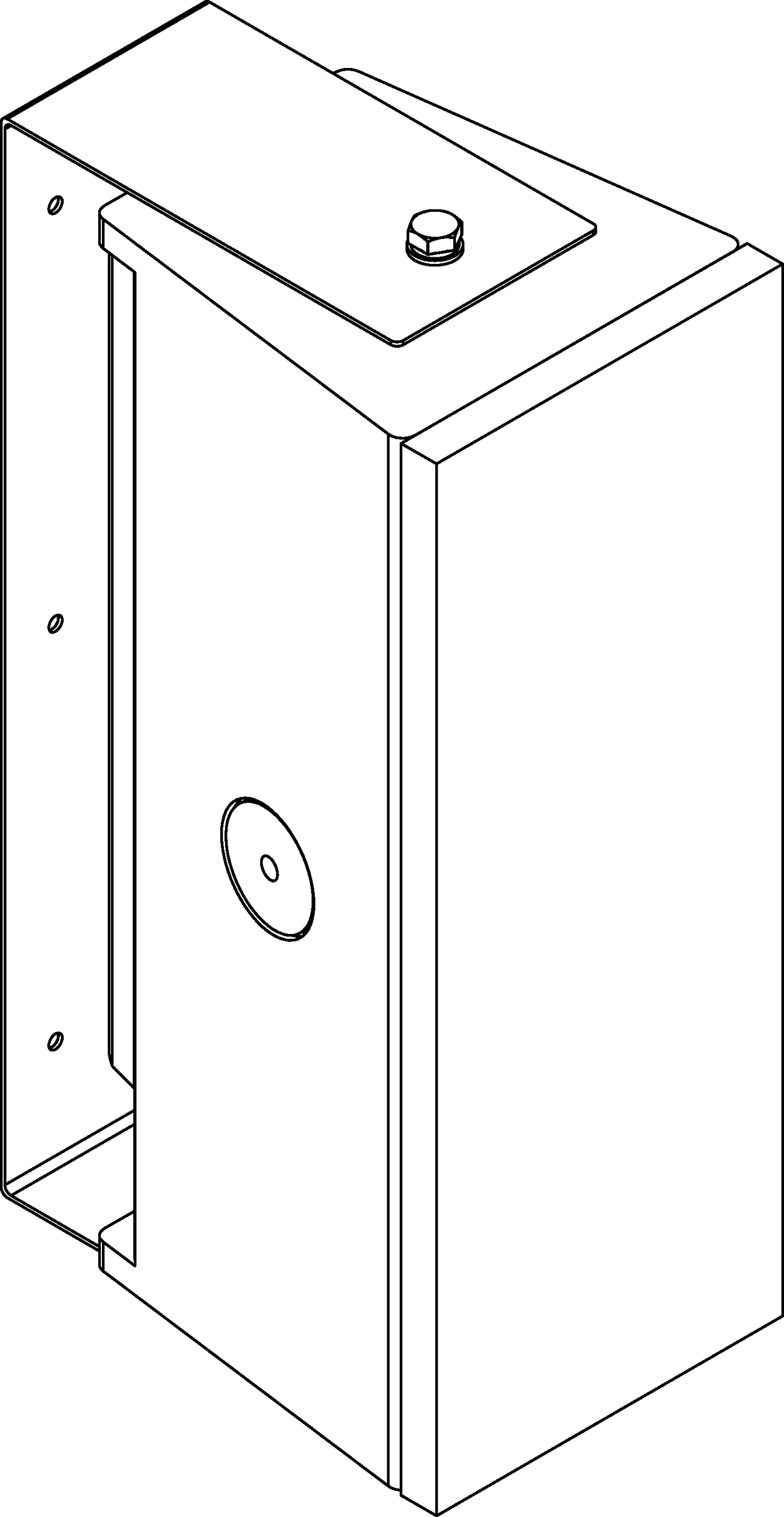

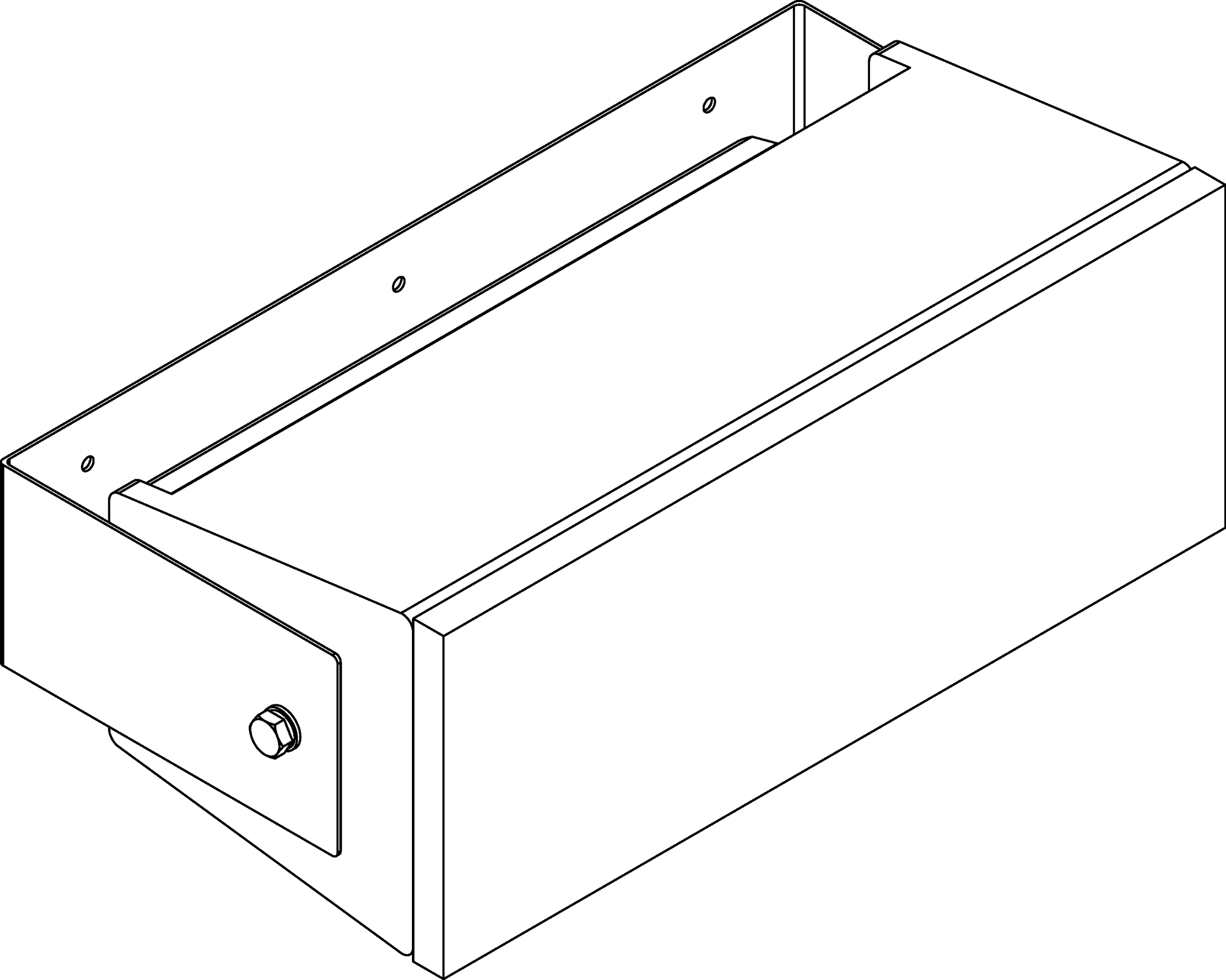

The MUB-UPM U-bracket, shown in the figure below, allows a UPM-1P or UPM-2P loudspeaker to be mounted to a wall, ceiling or floor.

MUB-UPM U-bracket

A single MUB-UPM U-bracket provides maximum flexibility for positioning and securing the U-bracket according to the needs of the design and/or the venue.

To secure the bracket, attach the adhesive-backed cork washer to the inside walls of the bracket and bolt the loudspeaker to the MUB-UPM bracket using the bolts and washers as shown above. Make sure the bolts are well-tightened.

Wall Mount

The MUB-UPM allows you to mount the UPM-1P or UPM-2P in both a vertical and horizontal orientation for wall mounting, as shown in the following figures.

Vertically wall-mounting the UPM-1P

Horizontally wall-mounting the UPM-1P

Ceiling Mount

For mounting the UPM-1P or UPM-2P loudspeaker on a ceiling, under-balcony or canopy area, the MUB-UPM U-bracket is effective and stable, as shown in the figure below.

Ceiling-mounting the UPM-1P

Floor Mount

The MUB-UPM can also be used to mount the UPM-1P or UPM-2P on the floor or stage lip, which is useful for monitoring or front-fill applications, as shown in the figure below.

Floor-mounting the UPM-1P

Caution

Always use mounting hardware appropriate for the construction of the surface where the MUB-UPM will be installed.

Always use mounting and rigging hardware that has been rated to meet or exceed the weight being hung.

Basic Troubleshooting

This section contains possible solutions to common problems encountered by UPM-1P and UPM-2P loudspeaker users and is not intended to be a comprehensive troubleshooting guide.

Make sure the AC power cable is the correct type for the regional voltage and that it is securely connected to the AC inlet, then unplug and reconnect the AC cable.

Use an AC voltmeter to verify that the AC voltage is within the ranges 105 - 130 V AC and 210 - 260 V AC (for 100 volt version, 90 - 100 V AC is recommended).

Check the voltage switch.

Check fuse.

Call Meyer Sound Technical Support.

Verify that the audio source (mixer, EQ, delay) is sending a valid signal.

Make sure the XLR cable is securely fastened to the XLR audio input connector.

Verify that the XLR cable is functioning by substituting another cable or by using the cable in question in a working system.

Send the audio signal to another loudspeaker to ensure signal presence and that the level is within the proper range. Turn the source level down before reconnecting the audio input and increase the level slowly to avoid a sudden blast of sound.

If possible, monitor the audio source with headphones.

Disconnect the audio input. If the noise persists, the problem is within the loudspeaker. In this case, return the unit to the factory or nearest authorized service center. If the hum ceases, the noise originates somewhere earlier in the signal path.

Make sure the XLR cable is securely fastened to the XLR audio input connector.

Send the audio signal to another loudspeaker to ensure signal presence and that the level is within the proper range. Turn the source level down before reconnecting the audio input and increase the level slowly to avoid a sudden blast of sound.

Hum or noise can be produced by a ground loop. Since the UPM-1P and UPM-2P are effectively ground-lifted, the loop must be broken elsewhere in the system.

Make sure the XLR cable is securely fastened to the XLR audio input connector.

Send the audio signal to another loudspeaker to ensure that the level is within the proper range. Turn the source level down before reconnecting the audio input and increase the level slowly to avoid a sudden blast of sound.

Monitor the audio source with headphones.

Turn down the level of the input signal to the speaker system.

This occurs in conditions where the heatsink temperature reaches 75° C (167° F), indicating that the amplifier is thermally overloaded.

Turn down the level of the input signal to the loudspeaker system.

Make sure there is sufficient airflow around the unit.

Avoid exposing the heatsink to direct sunlight if the ambient temperature is high.

See Amplification and Limiting, for a complete discussion about the cooling system.

Make sure the audio signal is full-range and has not been filtered in a previous stage of the signal chain. If possible, monitor the audio source with high-quality headphones.

Send the audio signal to another loudspeaker to ensure that the signal is full-range. Turn the source level down before reconnecting the audio input and increase the level slowly to avoid a sudden blast of sound.

Use a sine wave and/or pink noise generator to send a variety of frequencies to the loudspeaker.

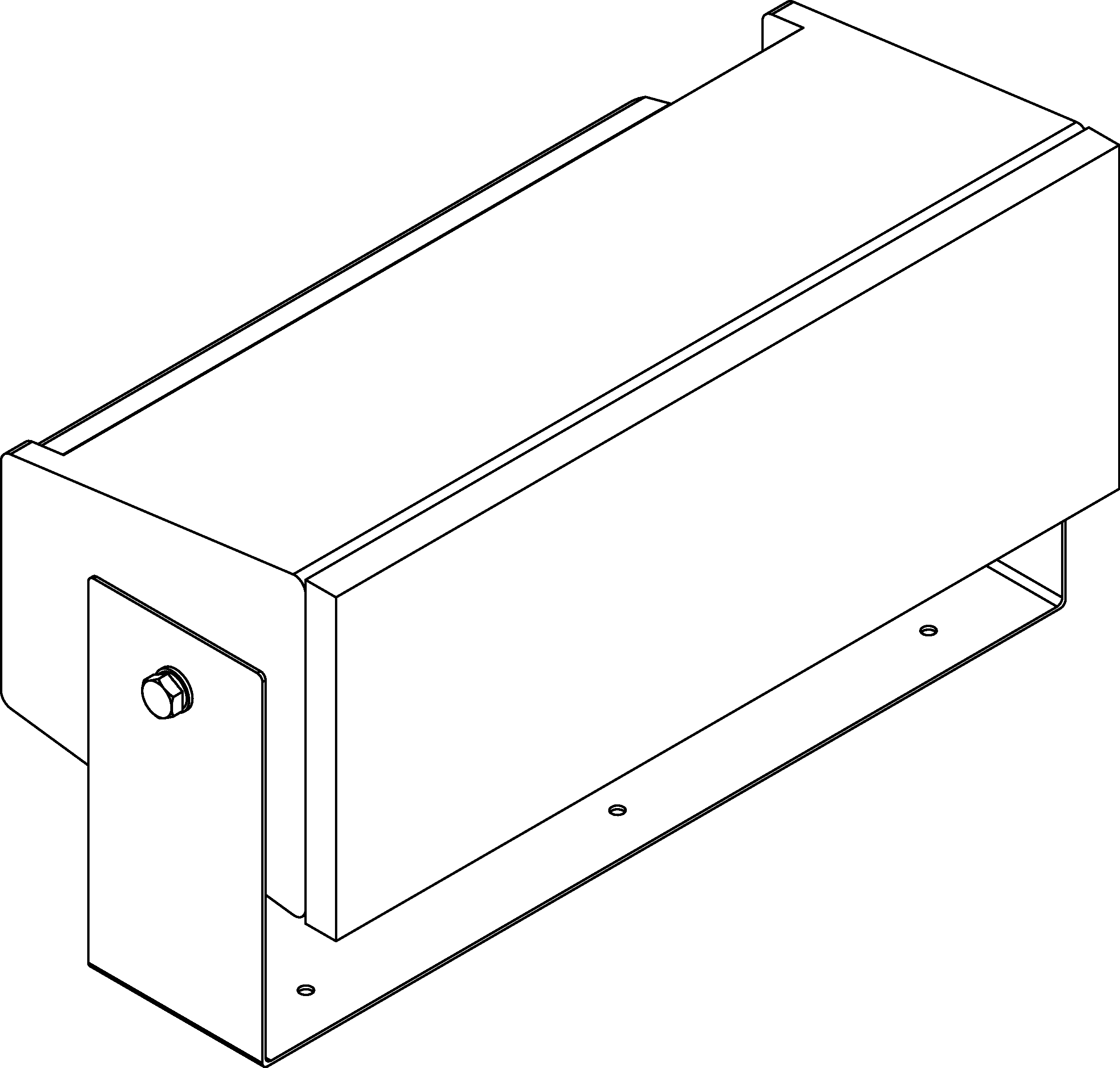

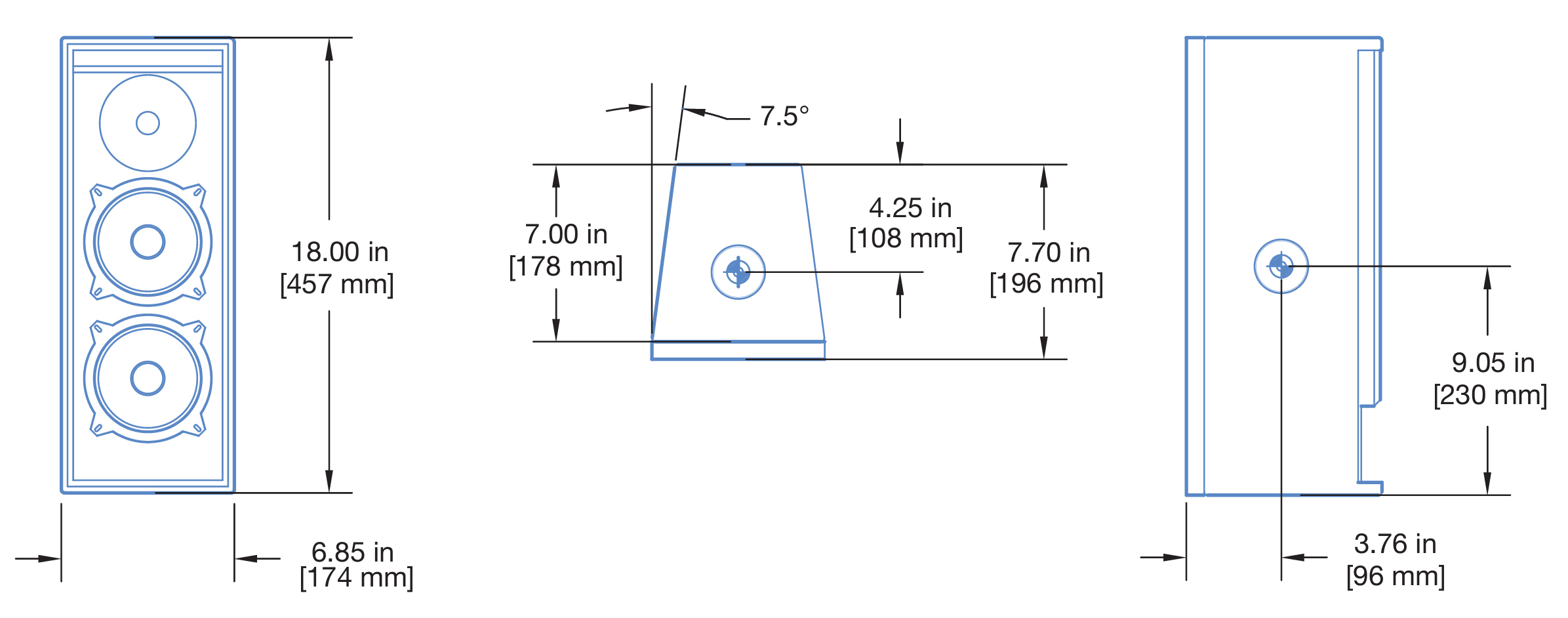

UPM-1P Dimensions

UPM-1P Dimensions

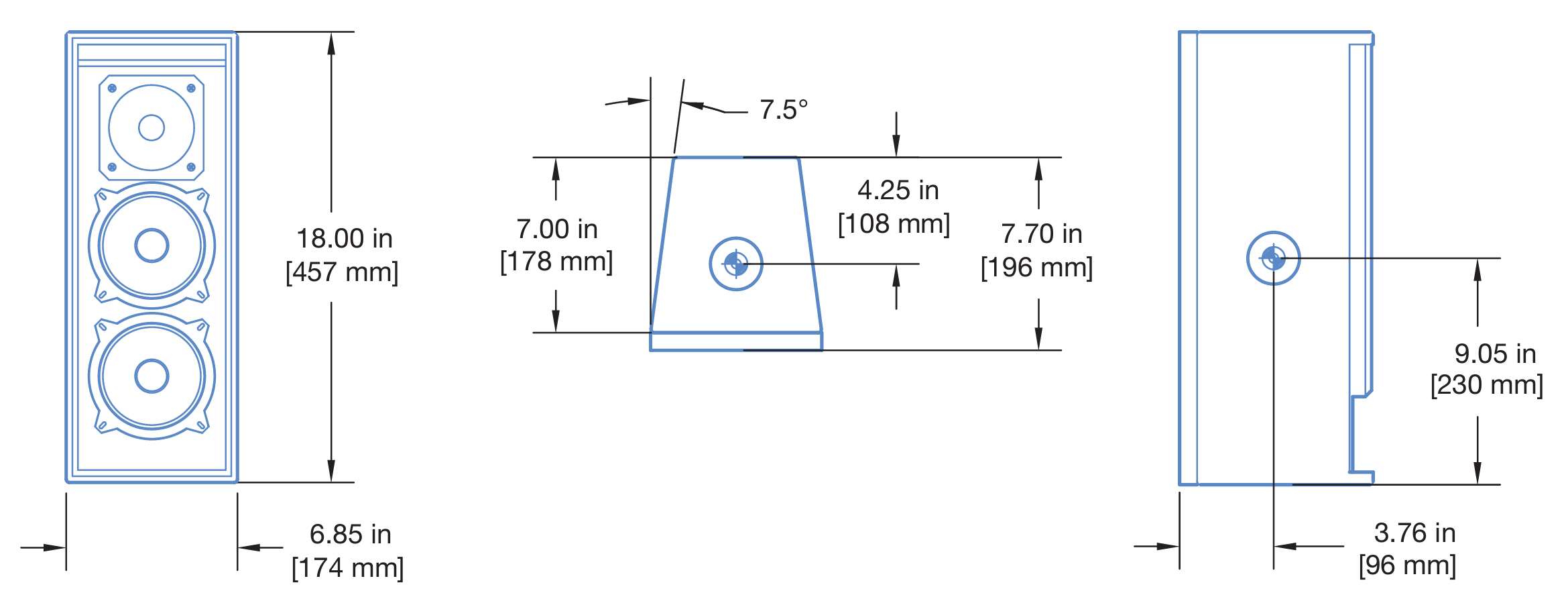

UPM-2P Dimensions

UPM-2P Dimensions