Operating Instructions — LEOPARD

Compact Linear Line Array Loudspeaker

The LEOPARD™ compact linear line array loudspeakers reproduce audio faithfully with tremendous power, superior intelligibility, and extremely low distortion. Rounding out Meyer Sound’s award-winning LEO® family of loudspeakers, LEOPARD loudspeakers deliver the same advantages of self-powered design, linear response, and precise directional control as their bigger siblings, LEO-M™ and LYON™.

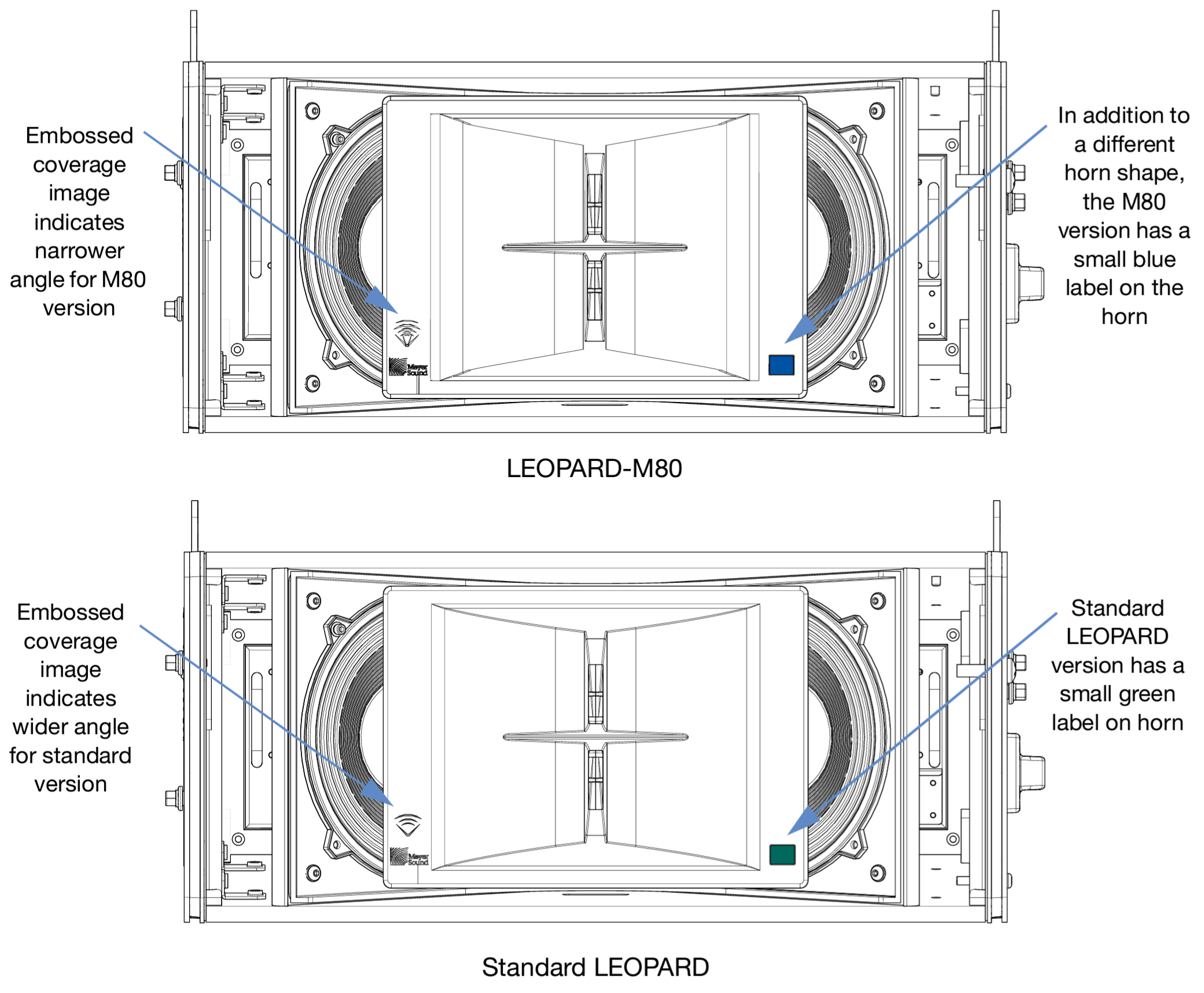

LEOPARD, with its 110° coverage, breaks new ground in loudspeaker array performance, providing exceptional phase coherence and consistent coverage in a light, compact cabinet, making it extremely versatile. Its innovative amplifier, driver, and horn designs ensure that LEOPARD systems reproduce any sound source with linearity over a wide dynamic range, from speech and classical music to rock and EDM.

The LEOPARD-M80 model provides exceptional phase coherence and extremely accurate and consistent 80° coverage, adding greater flexibility and accuracy to LEOPARD systems. LEOPARD-M80 can be used wherever narrow, more controlled coverage is needed in LEOPARD arrays, such as at the top, or even as the full array in some outfill applications. Because LEOPARD-M80 matches the acoustical characteristics and vertical coverage of LEOPARD, transition is seamless.

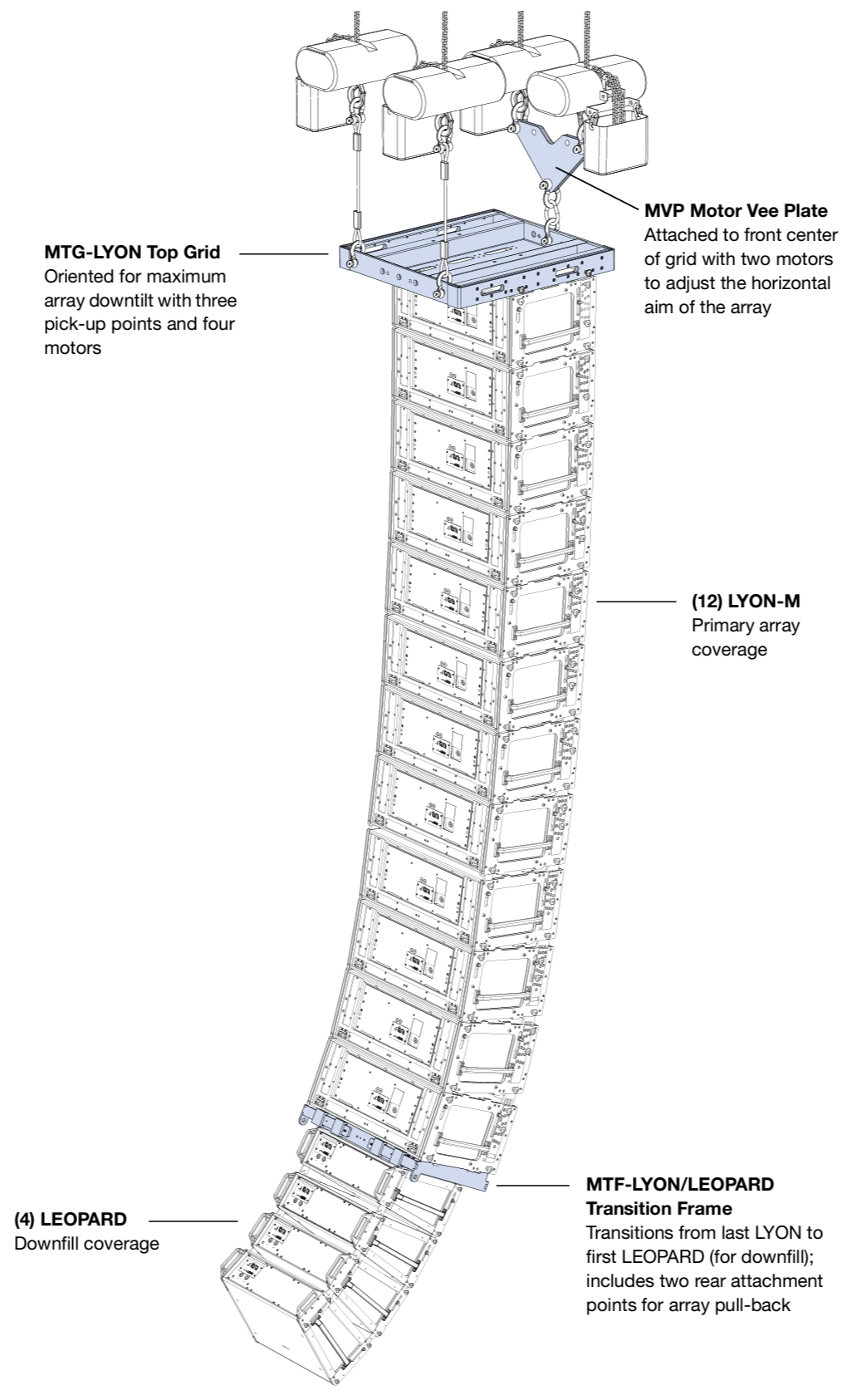

Both LEOPARD models are acoustically compatible to LYON and can be used for downfill at the bottom of LYON arrays, and as supplemental sidefill and outfill arrays in bigger LYON systems using the Galileo GALAXY Network Platform’s Product Integration settings.

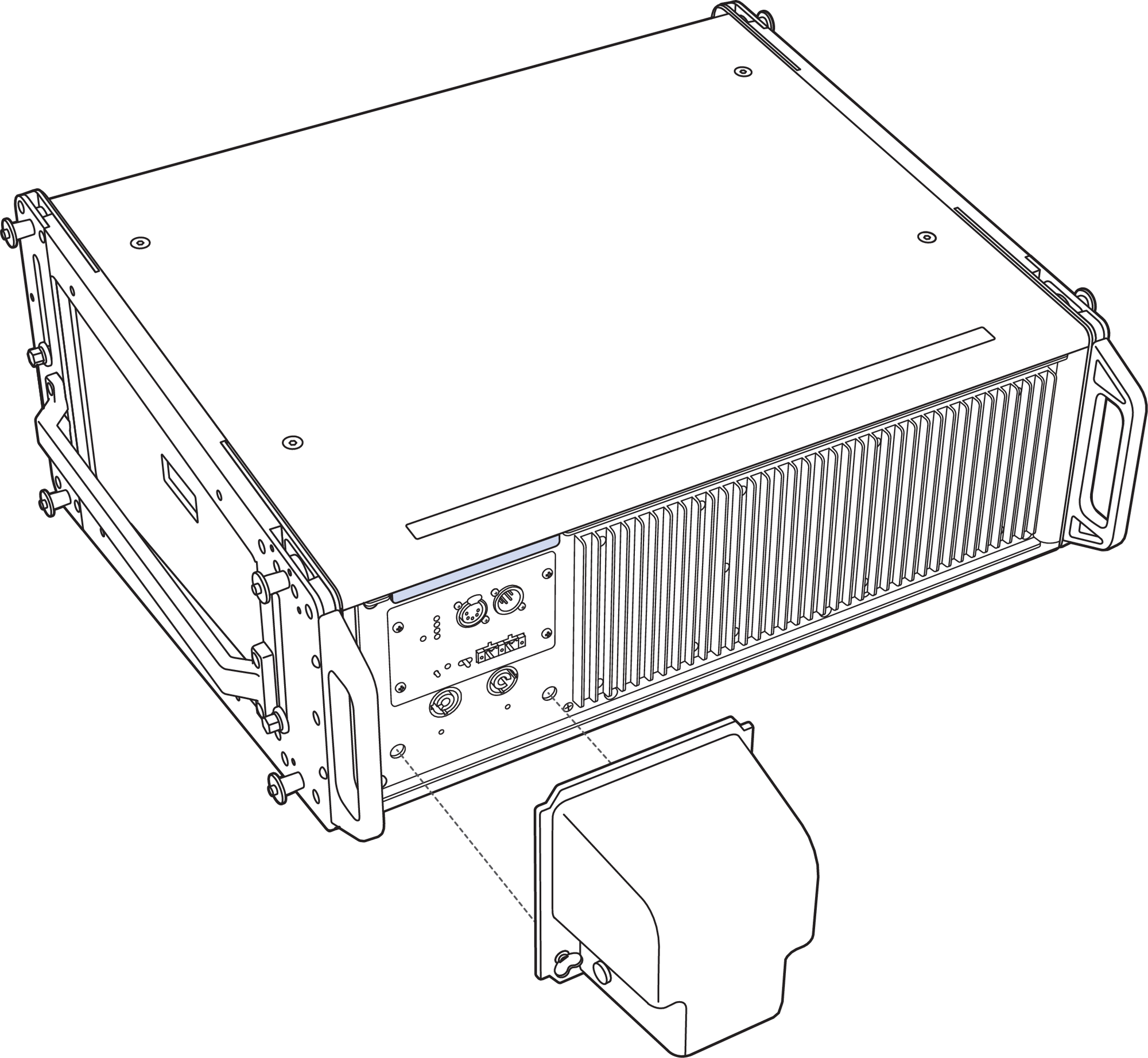

LEOPARD loudspeakers offer Native Mode (see Native Mode), a configuration optimized to yield excellent system performance right out of the box with minimal external processing. A class D amplifier affords unprecedented efficiency to LEOPARD, significantly lowering distortion while reducing power consumption and operating temperature. A single, field-replaceable module contains the on-board amplifier and control circuitry.

LEOPARD loudspeakers are portable and easy to configure. Their low weight and narrow profile make them well-suited for small- to medium-sized touring acts and fixed installations, where scalability and ease of rigging are essential.

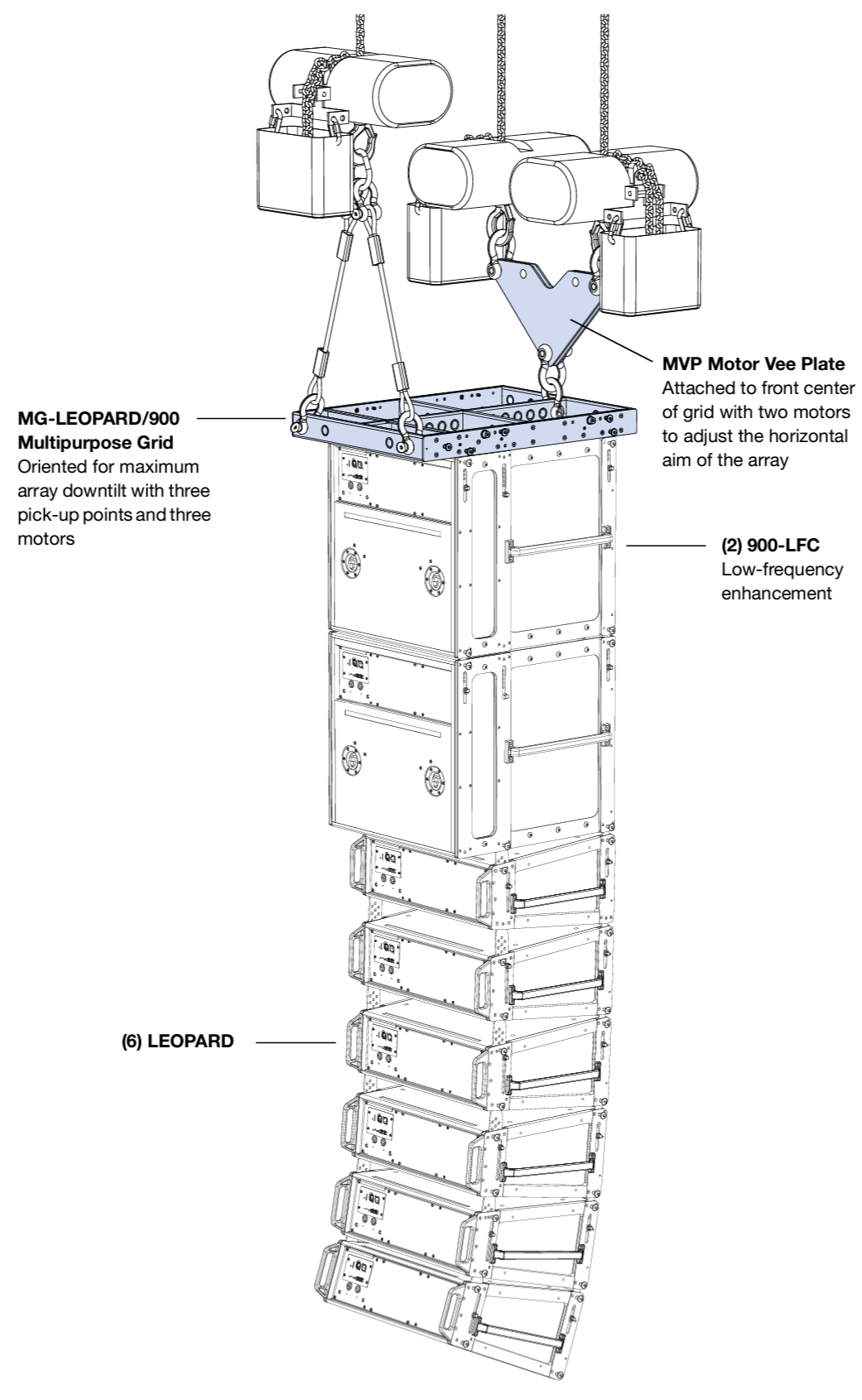

For low-frequency enhancement, LEOPARD loudspeakers pair with Meyer Sound’s 900-LFC low-frequency control element, which can be flown as part of LEOPARD arrays without transition hardware. The 900-LFC shares with LEOPARD the advantages of excellent power-to-size ratio, improved efficiency, and versatility.

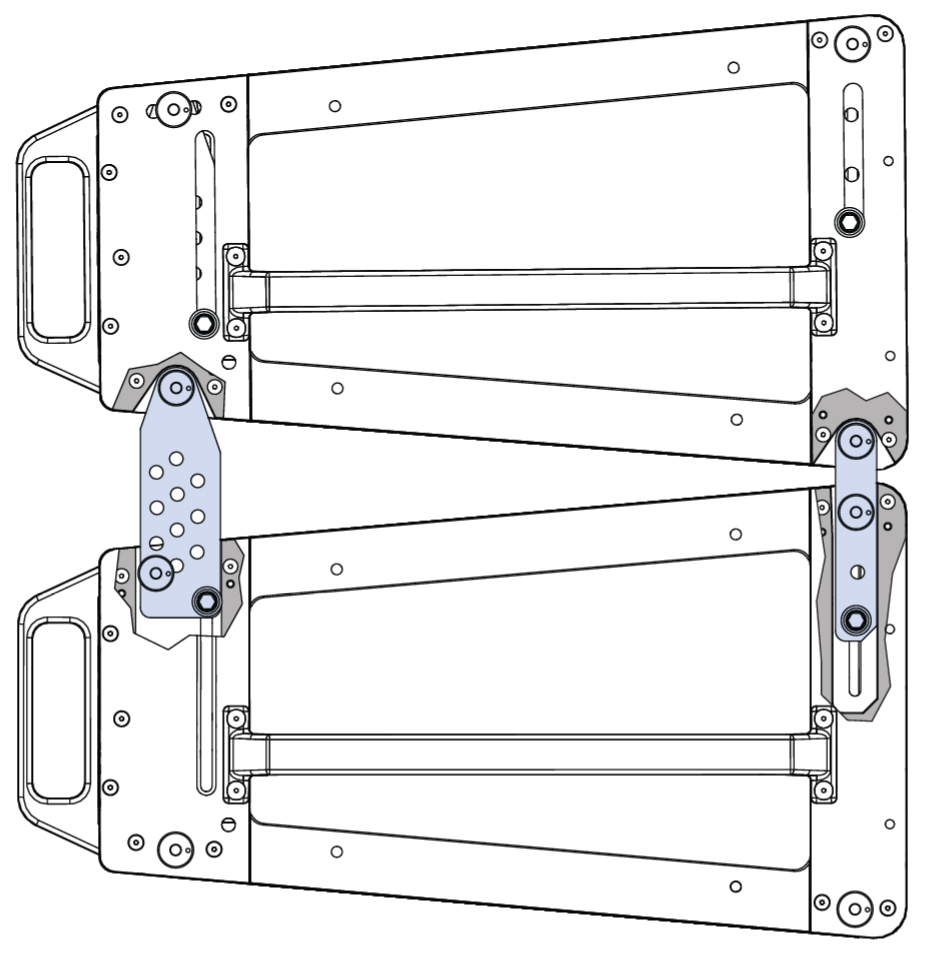

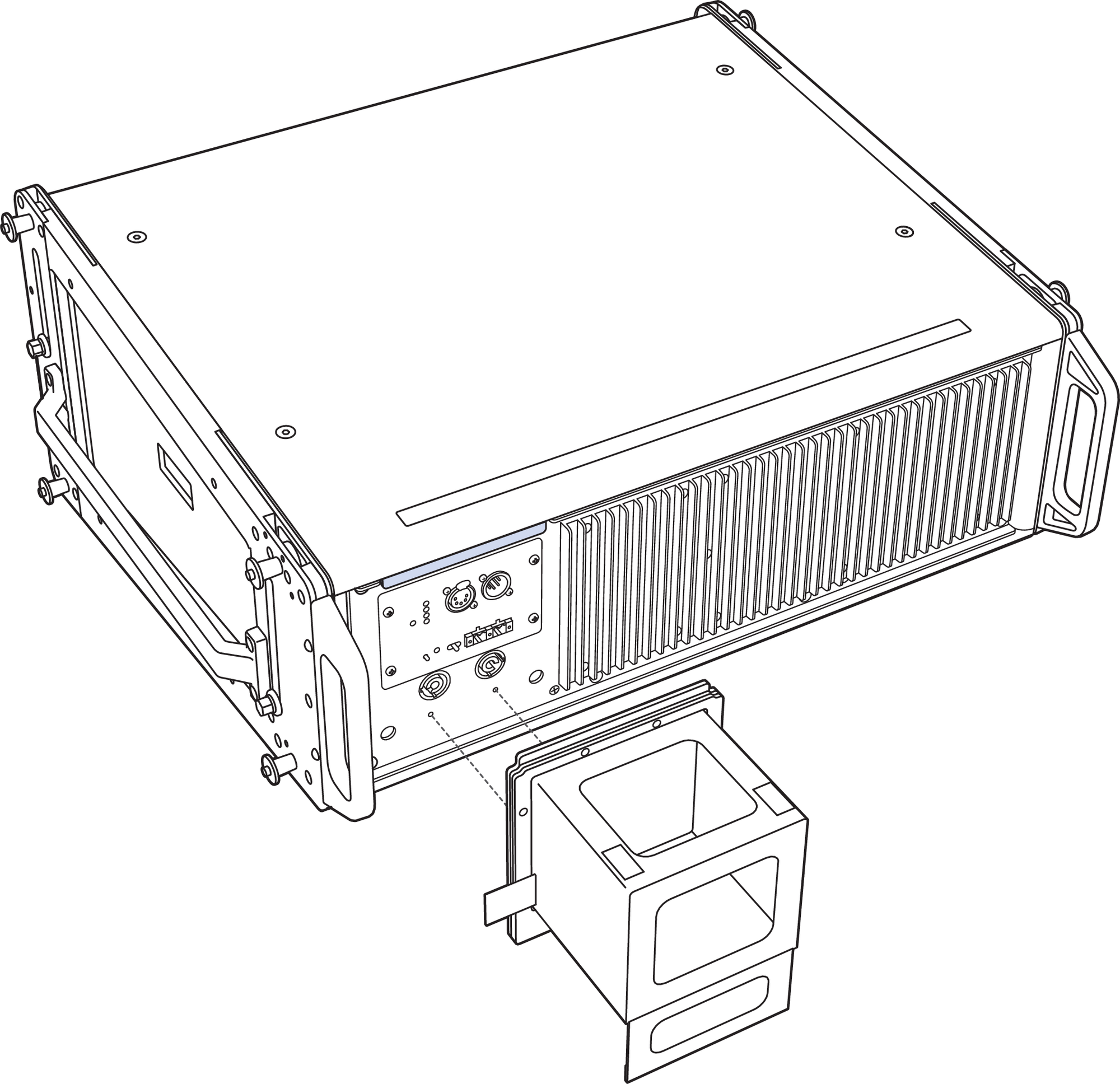

MG-LEOPARD/900 Multipurpose Grid with Mixed Array

In addition to working as a standalone system, LEOPARD can also be used as a supplemental fill loudspeaker in LEO-M and LYON systems. Applications that require more low-frequency headroom can use Meyer Sound’s 1100-LFC, which also integrates with LEOPARD systems.

Meyer Sound recommends driving LEOPARD systems with the Galileo® GALAXY Network Platform, which provides 24 bit, 96 kHz audio, matrix routing, alignment, and processing for array components. To guarantee optimum performance, use Meyer Sound’s MAPP™ System Design Tool to design LEOPARD systems, as this tool effectively anticipates system SPL and coverage requirements, and also helps verify rigging load ratings.

LEOPARD and 900-LFC loudspeakers work with Meyer Sound’s RMS™ remote monitoring system, which provides comprehensive monitoring of system parameters from a Mac® or Windows®-based computer.

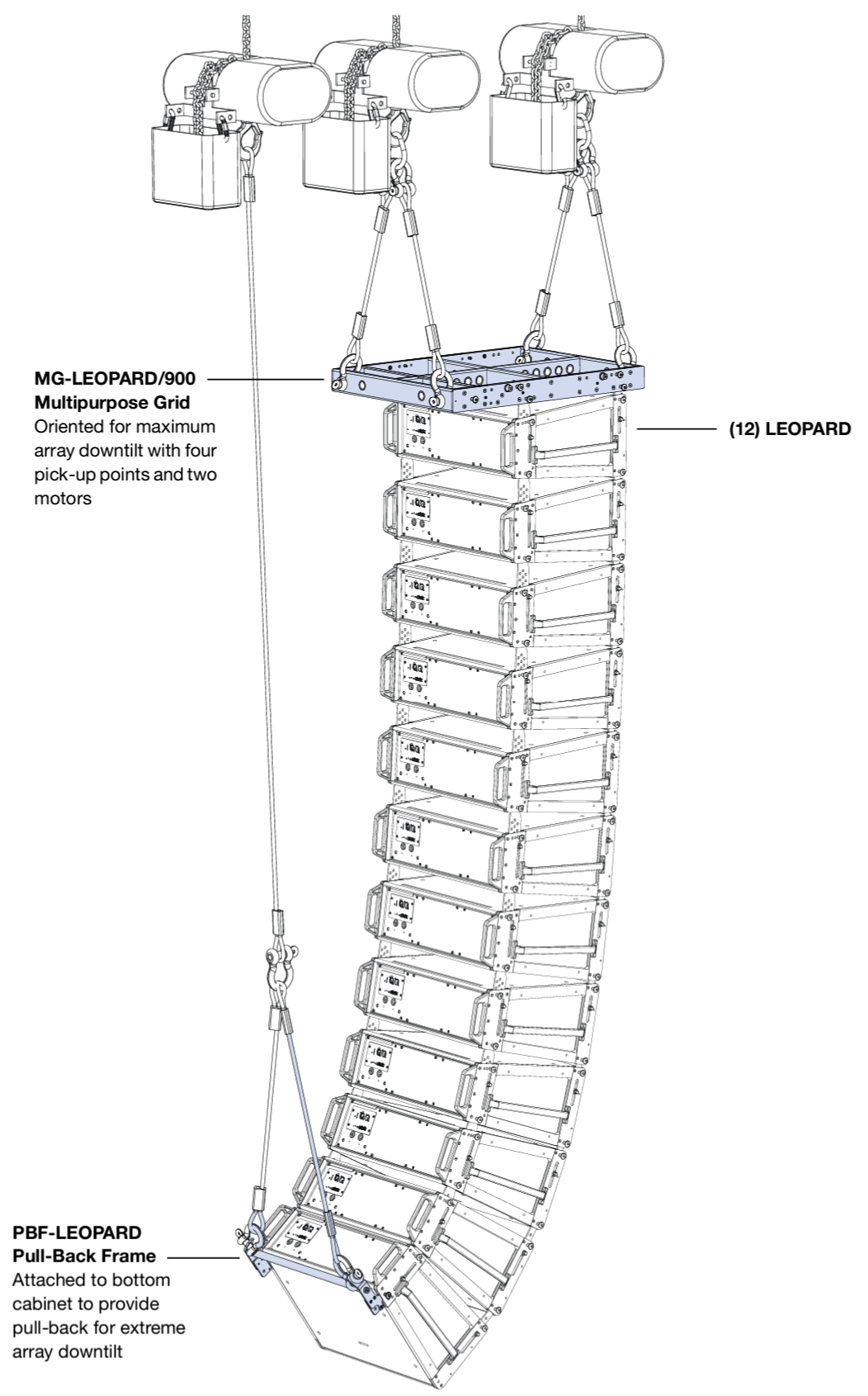

LEOPARD loudspeakers include Meyer Sound’s QuickFly® rigging with captive GuideALinks™ that facilitate easy setting of splay angles from 0.5° to 15°. Rigging options include the MG-LEOPARD/900 multipurpose grid shown in the figure above, MCF-LEOPARD caster frame (shown in the figure below), PBF-LEOPARD pull-back frame, and MTF-LYON/LEOPARD transition frame.

MCF-LEOPARD Caster Frame with LEOPARD Stack

Native Mode

LEOPARD and 900-LFC loudspeakers are optimized for use in certain flown and groundstacked configurations without any array compensation or other signal processing. This capability, called Native mode, allows LEOPARD/900-LFC systems to be deployed quickly with excellent results, without equalization, tuning, or use of presets.

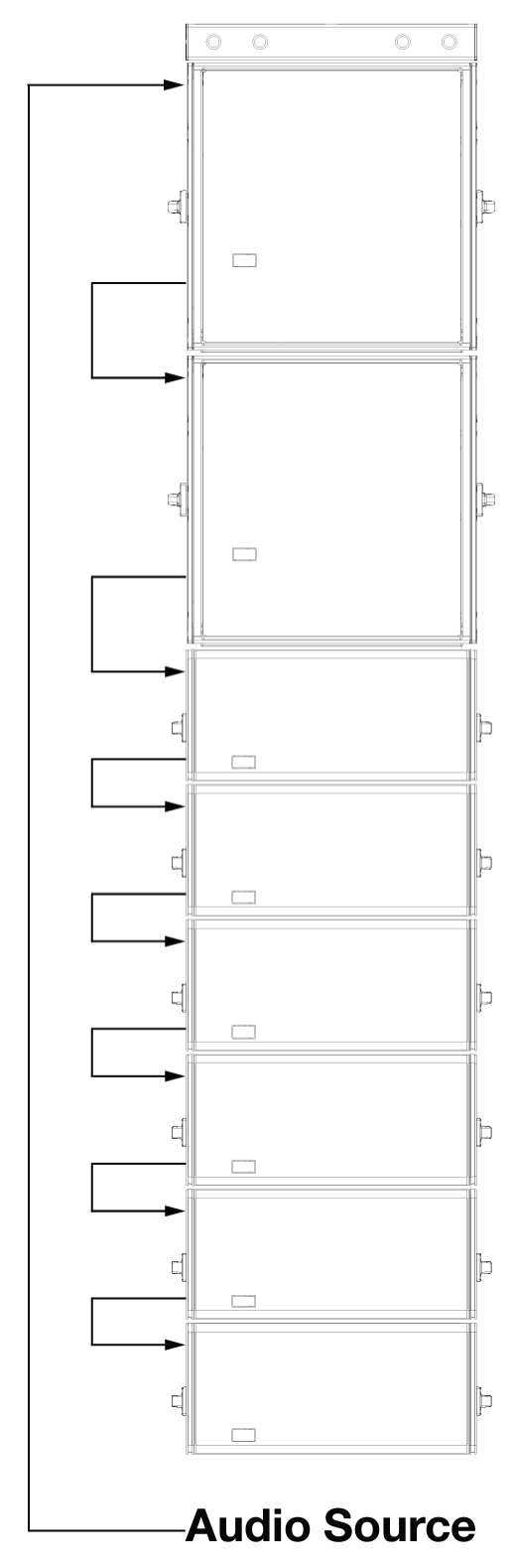

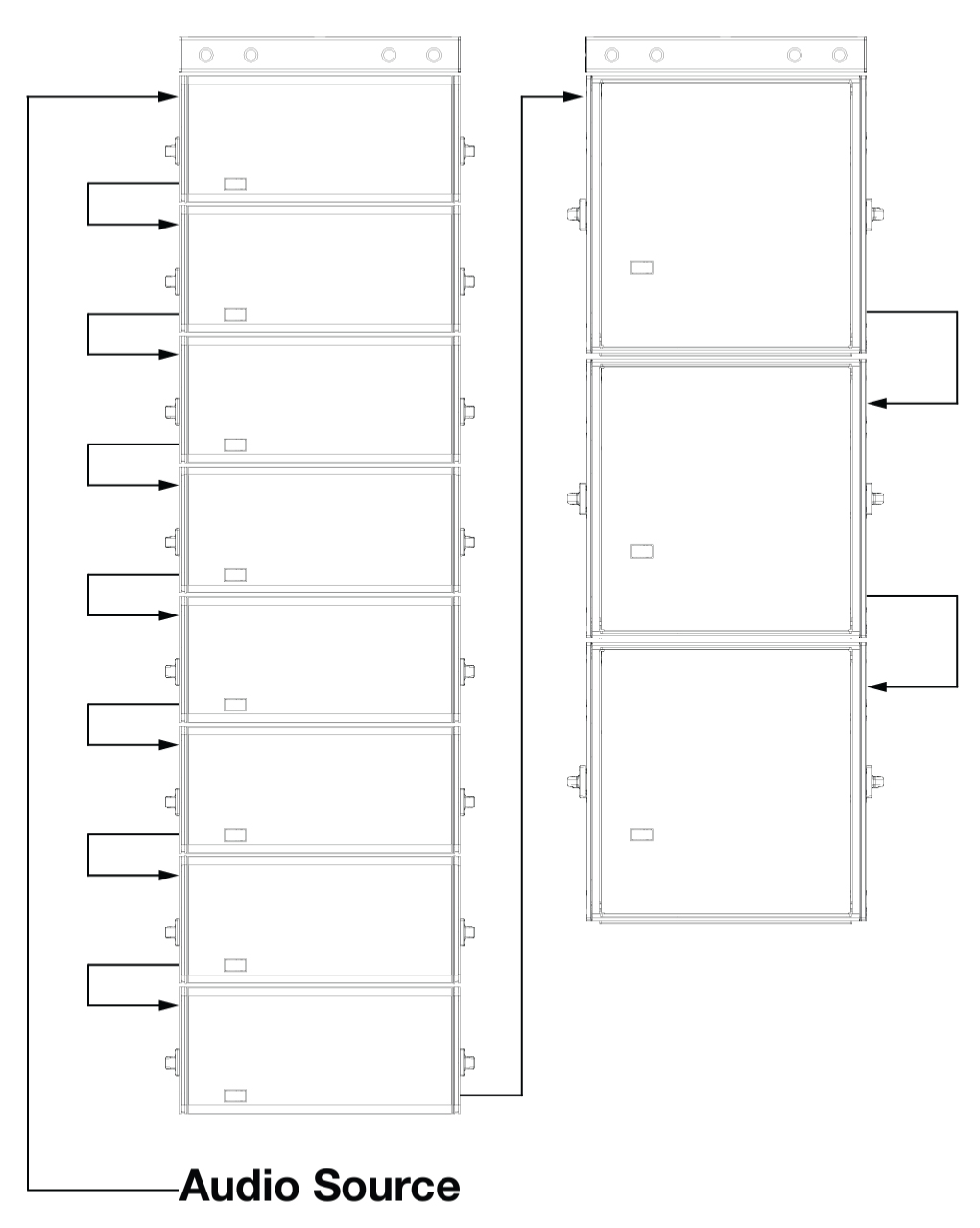

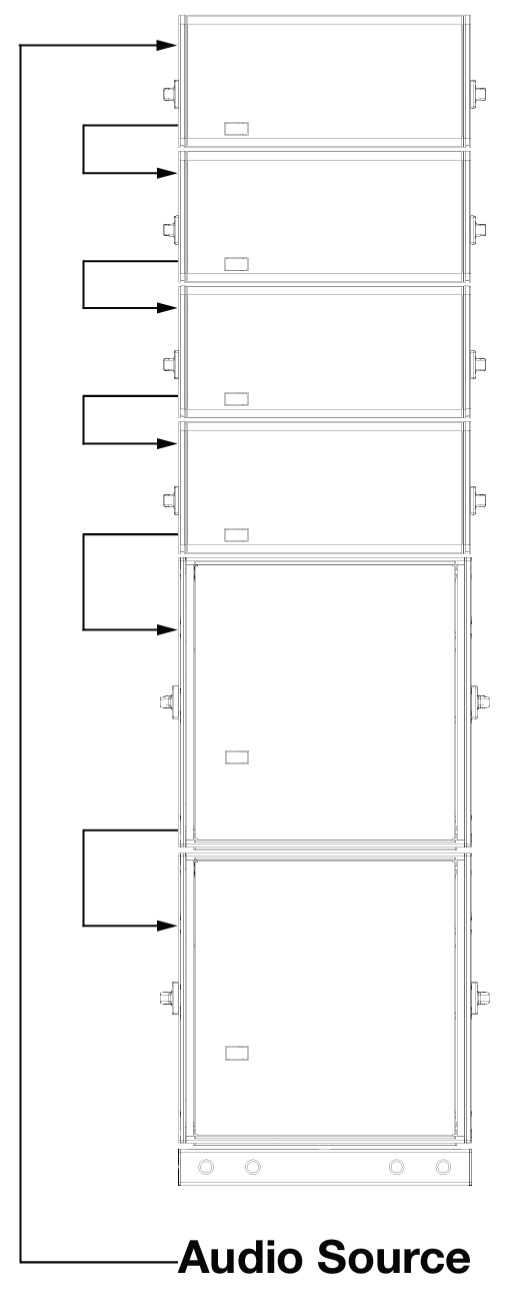

To use LEOPARD and 900-LFC loudspeakers in Native mode, send an identical, unmodified signal to each element in the array. The simplest way to accomplish this task is by looping the same, unprocessed source signal through all array elements.

The following coplanar configurations can be used in Native mode (without any signal processing):

Flown mixed arrays of LEOPARDs and 900-LFCs

Flown Mixed Array

Flown separate arrays of LEOPARDs and 900-LFCs

Flown Separate Arrays

Mixed groundstacks of LEOPARDs and 900-LFCs

Mixed Groundstack

Note

Native mode should not be used with more advanced configurations, such as those where 900-LFCs and LEOPARDs are not coplanar, or those requiring delay offsets to align subsystems or to create directional low-frequency control. These systems require additional processing.

For Native mode to work properly, the source signal must be correctly configured with the appropriate gain structure.

Caution

Make sure that all cabling for looped loudspeakers is wired correctly (Pin 1 to Pin 1, Pin 2 to Pin 2, and so forth) to prevent the polarity from being reversed. If one or more loudspeakers in a system have reversed polarity, frequency response and coverage will be significantly degraded.

Power Requirements

LEOPARD combines advanced loudspeaker technology with equally advanced power capabilities. Understanding power distribution, voltage and current requirements, and electrical safety guidelines is critical to the safe operation of LEOPARD.

AC Power Distribution

All components in an audio system (self-powered loudspeakers, mixing consoles, and processors) must be properly connected to an AC power distribution system, ensuring that AC line polarity is preserved and that all grounding points are connected to a single node or common point using the same cable gauge (or larger) as the neutral and line cables.

Caution

Make sure the voltage received by LEOPARD remains within its 90–264 V AC operating range. In addition, the ground line must always be used for safety reasons and the line-to-ground voltage should never exceed 250 V AC (typically 120 V AC from line to ground).

Before applying AC power to any Meyer Sound self-powered loudspeaker, make sure that the voltage potential difference between the neutral and earth-ground lines is less than 5 V AC when using single-phase AC wiring.

Note

Improper grounding of connections between loudspeakers and the rest of the audio system may produce noise or hum, or cause serious damage to the input and output stages of the system’s electronic components.

120V AC, 3-Phase Wye System (Single Line) — Line-Neutral-Earth/Ground

The figure below illustrates a basic 120V AC, 3-phase Wye distribution system with the loudspeaker load distributed across all three phases, with each loudspeaker connected to a single line and common neutral and earth/ground lines. This system delivers 120V AC to each loudspeaker.

120V AC, 3-Phase Wye System (Single Line to Loudspeakers)

Line-Line-Earth/Ground

The figure below illustrates a 120V AC, 3-phase Wye distribution system with each loudspeaker connected to two lines and a common earth/ground line. This configuration is possible because LEOPARD tolerates elevated voltages from the ground line and does not require a neutral line. This system delivers 208V AC to each loudspeaker.

120V AC, 3-Phase Wye System (Two Lines to Loudspeakers)

Tip

The 120 V AC, 3-phase Wye system with two lines is recommended because it allows loudspeakers to draw less current than with single-line systems, thereby reducing voltage drop due to cable resistance. It also excludes the potential of varying ground to neutral voltages producing an audible hum.

230V AC, 3-Phase Wye System (Single Line)

Line-Neutral-Earth/Ground

The figure below illustrates a basic 230V AC, 3-phase Wye distribution system with the loudspeaker load distributed across all three phases, with each loudspeaker connected to a single line and common neutral and earth/ground lines. This system delivers 230V AC to each loudspeaker.

230V AC, 3-Phase Wye System (Single Line to Loudspeakers)

Caution

For 230V AC, 3-phase Wye systems, never connect two lines to the AC input of LEOPARD, as the resulting voltage would exceed the upper voltage limit (275V AC) and will damage the loudspeaker.

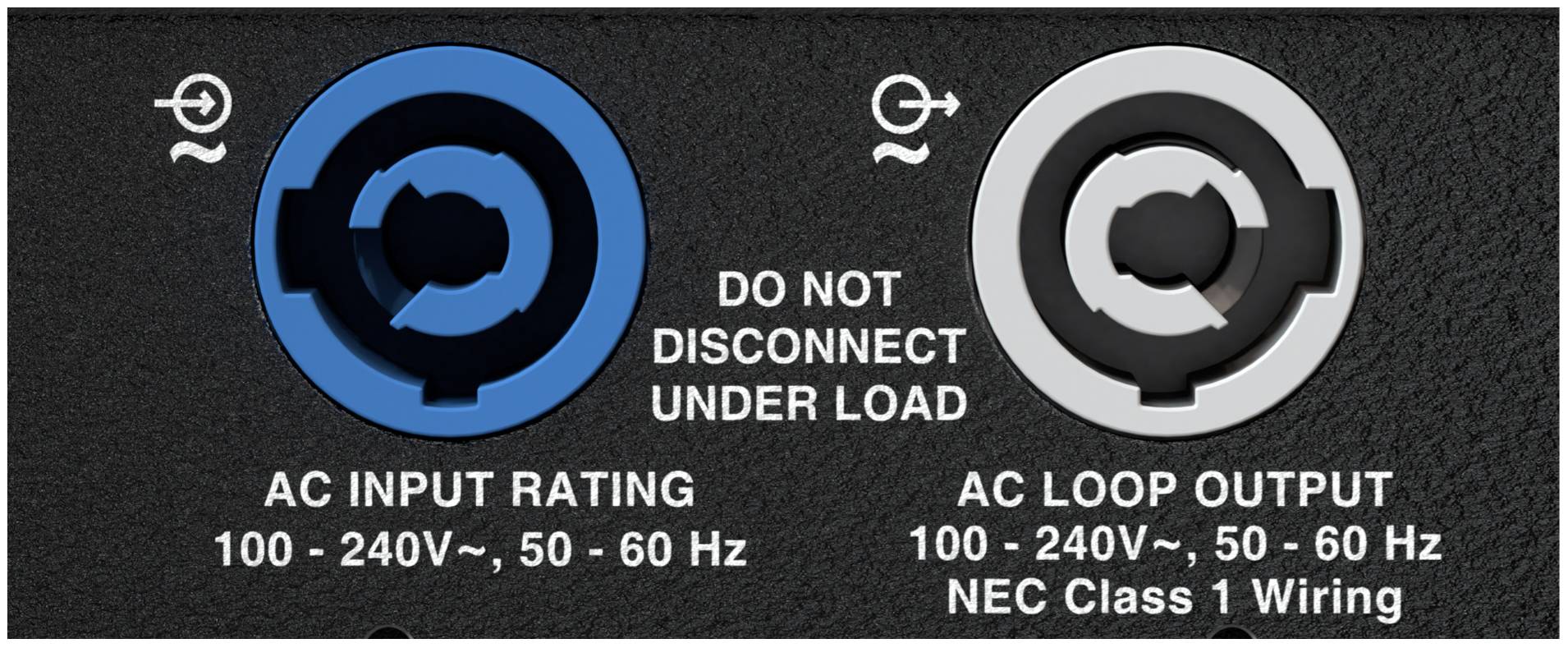

AC Connectors

The LEOPARD user panel includes two powerCON 20 connectors, as shown in the figure below, one for AC Input (blue) and one for AC Loop Output (gray).

AC Input (Left) and AC Loop Output (Right) Connectors

AC Input (Blue)

The blue AC Input connector supplies power to LEOPARD. The 3-conductor powerCON 20 is rated at 20 A and uses a locking connector that prevents accidental disconnections. A 10-foot AC power cable, rated at 15 A, is included with each loudspeaker. If you replace the included AC power cable, make sure to use a cable with the appropriate power plug (on the other end) for the area in which you will operate the loudspeaker. LEOPARD requires a grounded outlet. To operate safely and effectively, it is extremely important that the entire system be properly grounded.

The AC Input connector also supplies power to any additional loudspeakers connected to the loudspeaker’s gray Loop Output connector.

Caution

When looping AC power for loudspeakers, do not exceed the current capability of the AC Input connector (20 A) or the included AC power cable (15 A). Consider the total current draw for all loudspeakers on the circuit, including the first loudspeaker. See AC Loop Output (Gray) for more information.

AC Loop Output (Gray)

The gray AC Loop Output connector allows multiple LEOPARDs to be looped and powered from a single power source. The 3-conductor powerCON 20 is rated at 20 A and uses a locking connector that prevents accidental disconnections. For applications that require multiple LEOPARDs, connect the AC Loop Output of the first loudspeaker to the AC Input of the second loudspeaker, and so forth.

The maximum number of loudspeakers that can be looped from the AC Loop Output connector is determined by the voltage of the power source, the current draw of the looped loudspeakers, the circuit breaker rating, and the rating of the AC power cable connected to the first LEOPARD loudspeaker, as shown in the table below.

Circuit Breaker/ Connector Rating | 115 V AC | 230 V AC | 100 V AC |

|---|---|---|---|

15 A / 16 A | 4 looped (5 total) | 9 looped (10 total) | 3 looped (4 total) |

20 A | 5 looped (6 total) | 12 looped (13 total) | 4 looped (5 total) |

Note

Current draw for LEOPARD is dynamic and fluctuates as operating levels change. The indicated number of loudspeakers that can be looped assumes that operating levels are normal and not such that loudspeakers are constantly limiting.

LEOPARD ships with a gray powerCON 20 cable mount connector, rated at 20 A, for assembling AC looping cables. Assembled AC looping cables are also available from Meyer Sound.

Caution

When looping AC power for loudspeakers, do not exceed the current capability of the AC Input connector (20 A) or the included AC power cable (15 A). Consider the total current draw for all loudspeakers on the circuit, including the first loudspeaker, as shown in the table above.

Wiring AC Power Cables

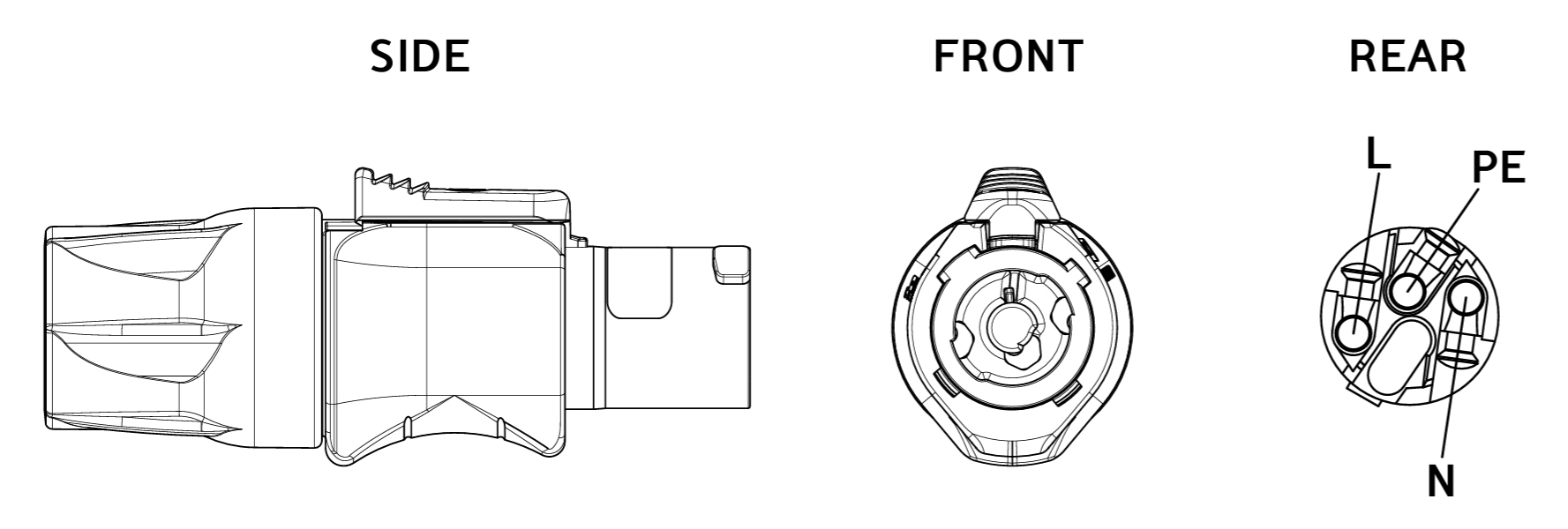

LEOPARD ships with a gray powerCON20 cable mount connector rated at 20A, for assembling AC looping cables, as shown in the figure below. The pins on the powerCON20 cable mount connector are labeled as follows:

L (Line)

N (Neutral)

PE (Protective Earth or Ground)

powerCON 20 Cable Mount Connector

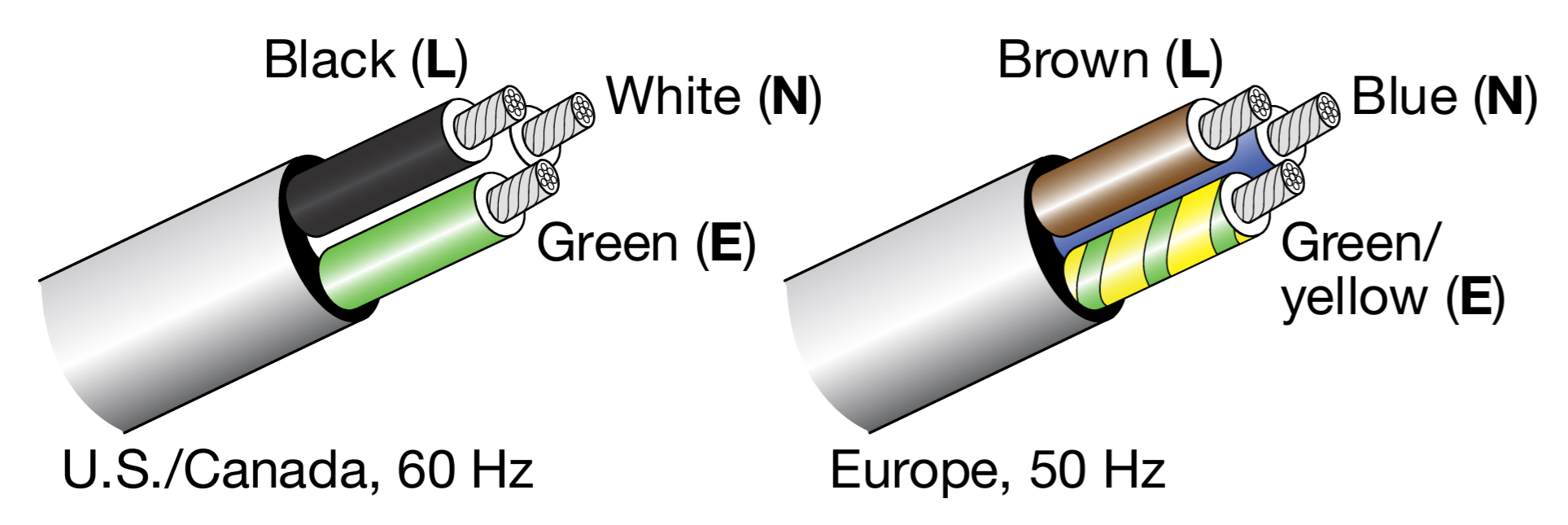

How AC power cables are wired is determined by the type of AC power distribution system used ( see AC Power Distribution). When wiring AC power cables for single-line systems, use one of the wiring schemes described in the table and illustrated in the figure below:

Wire Color | Attach to the Following Terminal | |

U.S. / Canada 60 Hz | European 50 Hz | |

Black | Brown | Hot or live (L |

White | Blue | Neutral (N) |

Green | Green or Yellow | Protective earth / ground (E or PE) |

AC Wiring Scheme, illustrated

Caution

When wiring AC power cables and distribution systems, it is important to preserve AC line polarity and connect the earth ground on both ends of the cable. LEOPARD requires a grounded connection. Always use a grounded outlet and plug. It is extremely important that the system be properly grounded to operate safely and properly. Do not ground-lift the AC cable.

LEOPARD Voltage Requirements

LEOPARD operates as intended when receiving AC voltage within the following range:

90–264 V AC, 50–60 Hz

If the voltage drops below 90 V, the loudspeaker uses stored power to continue operating temporarily; the loudspeaker powers off if the voltage does not return to its operating range.

If the voltage rises above 275 V, the power supply could become damaged.

Caution

The power source for LEOPARD should always operate within the required operating range, at least a few volts from the upper and lower limits. This ensures that AC voltage variations from the service entry—or peak voltage drops due to cable runs—will not cause the loudspeaker’s amplifier to cycle on and off or cause damage to the power supply.

LEOPARD Current Requirements

Current draw for loudspeakers is dynamic and fluctuates as operating levels change. Because different cables and circuit breakers heat up at varying rates, it is important to understand the following types of current ratings and how they affect circuit breaker and cable specifications.

Idle Current — The maximum rms current during idle periods.

Maximum Long-Term Continuous Current — The maximum rms current during a period of at least 10 seconds. The maximum long-term continuous current is used to calculate temperature increases for cables to ensure that the size and gauge of the cables conform to electrical code standards. The current rating is also used to select appropriately rated, slow-reacting thermal breakers, which are recommended for loudspeaker power distribution. In addition, the maximum long-term continuous current can be used to calculate the AC looping capability for LEOPARD loudspeakers.

Burst Current — The maximum rms current during a period of around 1 second. The burst current is used as a rating for magnetic breakers. It is also used for calcuating the peak voltage drop in long AC cable runs according to the following formula:

V pk (drop) = I pk x R (cable total)

Maximum Instantaneous Peak Current — A rating for fast-reacting magnetic breakers.

Use the information provided in the table below as a guide for selecting the gauge of cables and the circuit breaker ratings for the system’s operating voltage.

Current Draw | 115 V AC | 230 V AC | 100 V AC |

|---|---|---|---|

Idle | 0.46 A rms | 0.46 A rms | 0.49 A rms |

Maximum Long- Term Continuous | 3.0 A rms | 3.0 A rms | 3.4 A rms |

Burst | 4.4 A rms | 2.3 A rms | 5.5 A rms |

Maximum Instantaneous Peak | 12.6 A peak | 6.3 A peak | 14.5 A peak |

The minimum electrical service amperage required by a loudspeaker system is the sum of the maximum long-term continuous current for all loudspeakers. An additional 30 percent above the combined Maximum Long-Term Continuous amperages is recommended to prevent peak voltage drops at the service entry.

Note

For best performance, the AC cable voltage drop should not exceed 10 V (10 percent at 115 V and 5 percent at 230 V). This ensures that the AC voltage variations from the service entry—or peak voltage drops due to longer cable runs—do not cause the amplifier to cycle on and off.

Intelligent AC Power Supply

LEOPARD’s Intelligent AC™ power supply automatically selects the correct operating voltage (allowing the loudspeaker to be used internationally without manually setting voltage switches), eliminates high inrush currents with soft-start power up, suppresses high-voltage transients up to several kilovolts, filters common mode and differential mode radio frequencies (EMI), and sustains operation temporarily during low-voltage periods

Powering on LEOPARD

When powering on LEOPARD, the following startup events take place over several seconds.

Audio output is muted.

Voltage is detected and the power supply mode is automatically adjusted as necessary.

The power supply ramps up.

On the user panel, the Active/Status LED flashes multiple colors successively.

The Active/Status LED turns solid green, indicating the loudspeaker is unmuted and ready to output audio.

Caution

If the Active/Status LED does not turn solid green, or LEOPARD does not output audio after 10 seconds, remove AC power immediately and verify that the voltage is within the required range. If the problem persists, contact Meyer Sound Technical Support.

Electrical Safety Guidelines

Make sure to observe the following important electrical and safety guidelines.

The powerCON 20 connector should not be engaged or disengaged when under load or energized. Either de-energize- energize or disconnect the other end of the cable.

LEOPARD requires a grounded outlet. Always use a grounded outlet and plug.

Do not use a ground-lifting adapter or cut the AC cable ground pin.

Do not exceed the current capability of the 20 A AC Input connector for the loudspeaker. When looping loudspeakers, consider the total current draw for all loudspeakers on the circuit, including the first loudspeaker.

Make sure the AC power cable for the loudspeaker has the appropriate power plug (on the other end) for the area in which you will operate the loudspeaker. In addition, the AC power cable must be rated for the total current draw of all loudspeakers looped from the power source.

Do not operate the loudspeaker if the power cable is frayed or broken.

Keep all liquids away from LEOPARD loudspeakers to avoid hazards from electrical shock.

Amplification and Audio

LEOPARD’s drivers are powered by a proprietary three-channel, open-loop, class D amplifier. The audio signal is processed with an electronic crossover plus correction filters for flat phase and frequency responses, and by driver protection circuitry. Each channel has peak and rms limiters that prevent driver over-excursion and regulate voice coil temperatures.

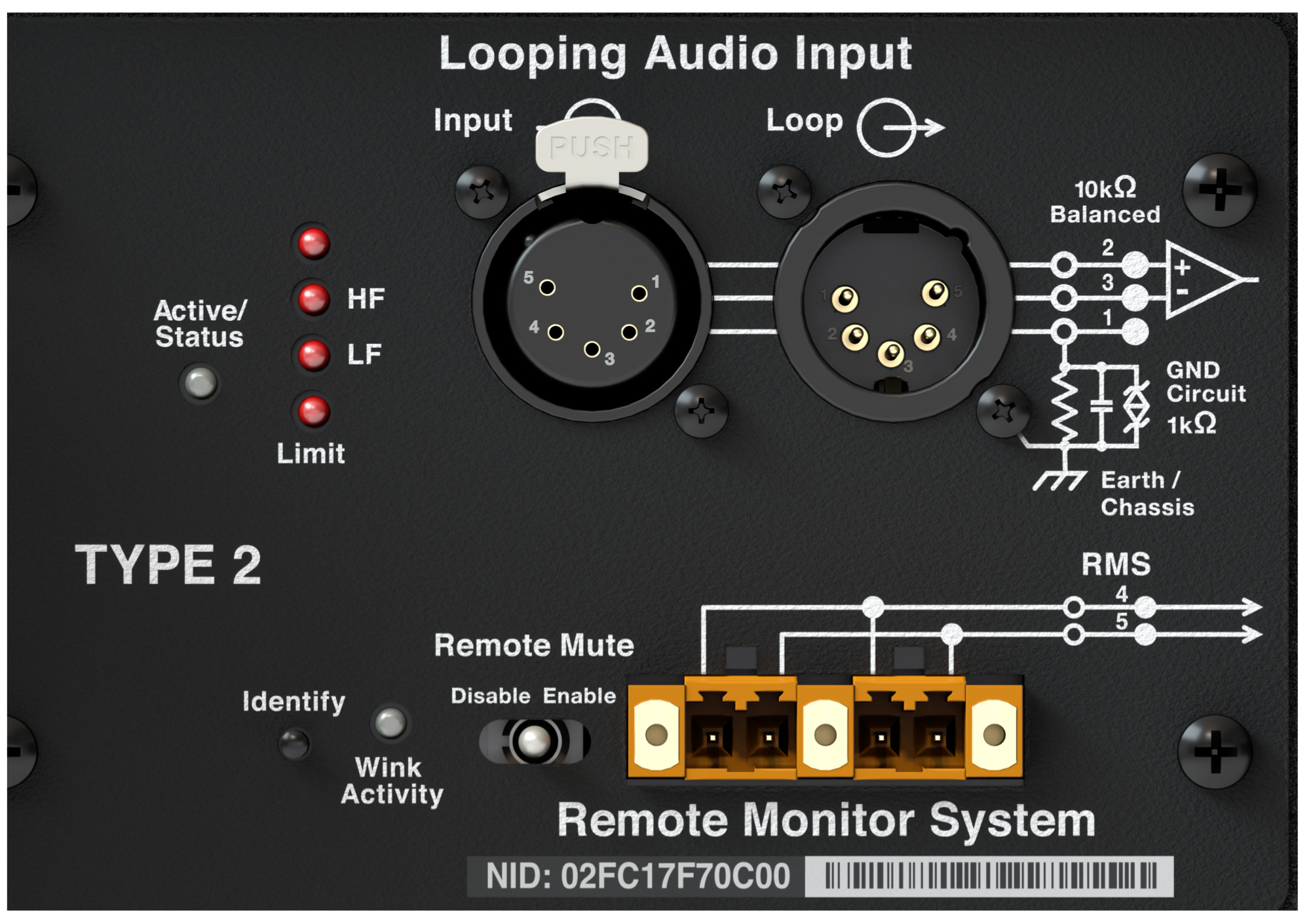

The LEOPARD user panel, shown in the figure below, includes Input and Loop output connectors for audio, Limit and Active LEDs, and RMS connectors and controls (see RMS Remote Monitoring System).

LEOPARD User Panel

Audio Connectors

LEOPARD is available with XLR 5-pin or 3-pin connectors for audio Input and audio Loop output, as shown in the figures below. XLR 5-pin connectors accommodate both balanced audio and RMS signals.

XLR 5-Pin Audio Connectors, Input and Loop Output

XLR 3-Pin Audio Connectors, Input and Loop Output

Audio Input (XLR 3-Pin or 5-Pin Female)

The XLR 3-pin or 5-pin female Input connector accepts balanced audio signals with an input impedance of

10 kOhm. The connector uses the following wiring scheme:

Pin 1 — 1 kOhm to chassis and earth ground (ESD clamped)

Pin 2 — Signal (+)

Pin 3 — Signal (–)

Pin 4 — RMS (polarity insensitive)

Pin 5 — RMS (polarity insensitive)

Case — Earth (AC) ground and chassis

Note

Pins 4 and 5 (RMS) are included only with XLR 5-pin connectors.

Pins 2 and 3 carry the input as a differential signal. Pin 1 is connected to earth through a 1 kOhm, 1000 pF, 15 V clamped network. This circuitry provides virtual ground lift for audio frequencies while allowing unwanted signals to bleed to ground. Make sure to use balanced XLR audio cables with pins 1–3 connected on both ends. Telescopic grounding is not recommended and shorting an input connector pin to the case may cause a ground loop, resulting in hum.

Tip

If unwanted noise or hiss is produced by the loudspeaker, disconnect its input cable. If the noise stops, there is most likely nothing wrong with the loudspeaker. To locate the source of the noise, check the audio cable, source audio, AC power, and electrical ground.

Audio Loop Output (XLR 3-Pin or 5-Pin Male)

The XLR 3-pin or 5-pin male Loop output connector allows multiple loudspeakers to be looped from a single audio source. The Loop output connector uses the same wiring scheme as the Input connector (see “Audio Input (XLR 3-Pin or 5-Pin Female)” on page 11). For applications that require multiple LEOPARDs, connect the Loop output of the first loudspeaker to the Input of the second loudspeaker, and so forth.

Note

The Loop output connector is wired in parallel to the Input connector and transmits the unbuffered source signal even when the loud- speaker is powered off.

Calculating Load Impedance for Looped Audio Signals

To avoid distortion when looping multiple loudspeakers, make sure the source device can drive the total load impedance of the looped loudspeakers. In addition, the source device must be capable of delivering approximately 20 dBV (10 V rms into 600 ohms) to yield the maximum SPL over the operating bandwidth of the loudspeakers.

To calculate the load impedance for the looped loudspeakers, divide 10 kOhms (the input impedance for a single loudspeaker) by the number of looped loudspeakers. For example, the load impedance for ten LEOPARDs is 1000 ohms (10 kOhms / 10). To drive this number of looped loudspeakers, the source device should have an output impedance of 100 ohms or less. This same rule applies when looping LEOPARDs with other Meyer Sound self-powered loudspeakers.

Note

Most source devices are capable of driving loads no less than 10 times their output impedance.

Tip

Audio outputs from Meyer Sound’s Galileo GALAXY Network Platform have an output impedance of 50 ohms. Each output can drive up to 20 Meyer Sound (10 kOhm) loudspeakers without distortion.

Caution

Make sure that all cabling for looped loudspeakers is wired correctly (Pin 1 to Pin 1, Pin 2 to Pin 2, and so forth) to prevent the polarity from being reversed. If one or more loudspeakers in a system have reversed polarity, frequency response and coverage will be significantly degraded.

TruPower Limiting

LEOPARD employs Meyer Sound’s advanced TruPower® limiting. Conventional limiters assume a constant loudspeaker impedance and set the limiting threshold by measuring voltage alone. This method is inaccurate because loudspeaker impedances change as frequency content in the source material changes, and as thermal values for the loudspeaker’s voice coil and magnet vary. Consequently, conventional limiters often begin limiting prematurely, which reduces system headroom and dynamic range.

In contrast, TruPower limiting anticipates varying loudspeaker impedances by measuring both current and voltage to compute the actual power dissipation in the voice coil. This approach improves performance, both before and during limiting, by allowing the driver to produce the maximum SPL across its entire frequency range, while also retaining signal peaks. TruPower limiting also eliminates power compression at high levels over lengthy periods, which helps regulate voice coil temperatures, thereby extending the life of the driver.

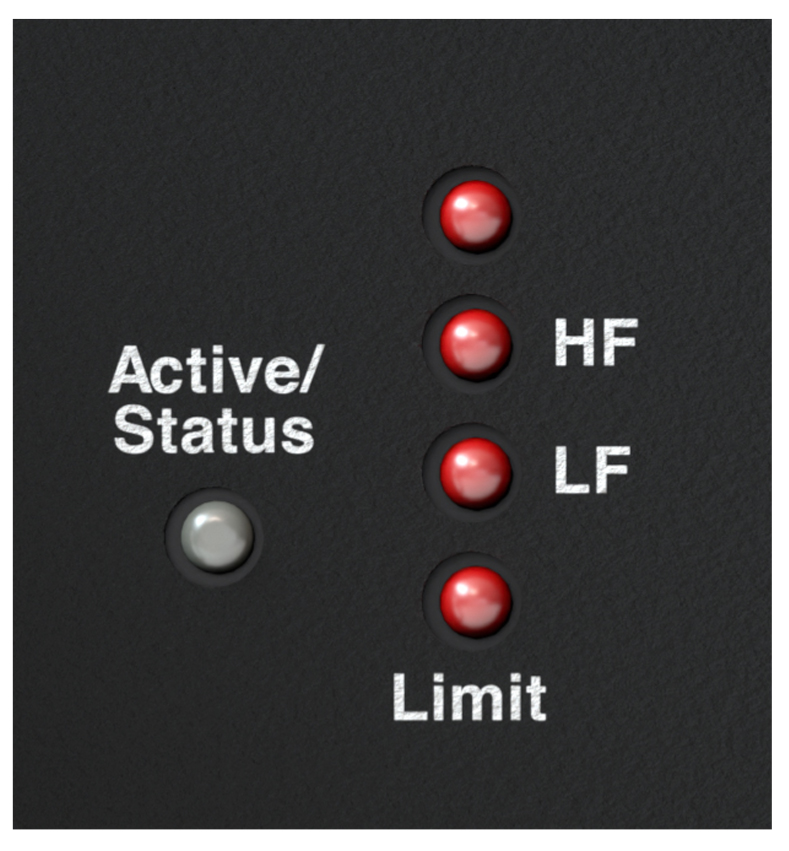

HF and LF Limit LEDs

The low- and high-frequency drivers for LEOPARD are powered by separate amplifier channels, each with their own limiter. Limiting activity is indicated with two Limit LEDs on the user panel, as shown i n the figure below. The HF Limit LED indicates limiting for the high-frequency channel and the LF Limit LED indicates limiting for the low-frequency channel.

LEOPARD Limit LEDs

When engaged, the limiters not only protect the drivers but also prevent signal peaks from causing excessive distortion in the amplifier channels, thereby preserving headroom and maintaining smooth frequency response at high levels.

When levels return to normal, below the limiter thresholds, limiting ceases.

LEOPARD performs within its acoustical specifications at normal temperatures when the Limit LEDs are unlit, or when the LEDs are lit for 2 seconds or less and then turn off for at least 1 second. If the LEDs remain lit for longer than 3 seconds, the loudspeaker enters hard limiting where:

Increases to the input level have no effect

Distortion increases due to clipping

Drivers are subjected to excessive heat and excursion, thereby compromising their lifespan

Caution

The Limit LEDs indicate when a safe, optimum level is exceeded. If a LEOPARD loudspeaker system begins to limit before reaching the desired SPL, consider adding more loudspeakers to the system.

Amplifier Cooling System

LEOPARD is convection cooled. The amplifier’s heat sink provides natural convection cooling from the air flowing near its fins. When exposed to high ambient temperatures or when driven continuously at high output levels, a variable-speed fan circulates air internally to ensure that LEOPARD remains operational.

Caution

To keep LEOPARD from overheat- ing, allow at least 6 inches behind the cabinet for proper ventilation.

LEOPARD’s heat sink can reach temperatures up to 80 °C (176 °F) during extreme operation. Wait 15 minutes for the loudspeaker to cool before touching.

Active/Status LED

During normal operation, when LEOPARD is powered on, the Active/Status LED is solid green. If the loudspeaker encounters a hardware fault, or the loudspeaker begins to overheat, the LED flashes red. In some instances, the loudspeaker will continue to output audio while the LED flashes red, though with a reduction in the limiter threshold and acoustic output to protect the loudspeaker.

If a loudspeaker is overheating (for RMS-equipped loudspeakers, you can verify this situation in Compass RMS), a reduction in SPL may be necessary. If, after a reduction in SPL and an appropriate cooling period, the Active/Status LED continues to flash red (does not return to solid green), contact Meyer Sound Technical Support.

If the Active/Status LED flashes red and the loudspeaker does not output audio, contact Meyer Sound Technical Support immediately.

Caution

If a LEOPARD loudspeaker system consistently overheats before reaching the desired SPL, consider adding more loudspeakers to the system.

Note

During startup, the Active/Status LED flashes multiple colors successively. For more information about the power on sequence, see “Intelligent AC Power Supply” on page 8.

Tip

When LEOPARD is connected to an RMS network, the Compass RMS software provides additional feedback on the loudspeaker’s hardware status and operating temperature. For more information, see RMS Remote Monitoring System.

QuickFly Rigging

Important Safety Considerations

When installing Meyer Sound loudspeakers and subwoofers, the following precautions should always be observed:

All Meyer Sound products must be used in accordance with local, state, federal, and industry regulations. It is the owner’s and user’s responsibility to evaluate the reliability of any rigging method for their application. Rigging should only be carried out by experienced professionals.

Use mounting and rigging hardware that has been rated to meet or exceed the weight being hung.

Make sure to attach mounting hardware to the building’s structural components (roof truss), and not just to the wall surface.

Make sure bolts and eyebolts are tightened securely. Meyer Sound recommends using Loctite® on all threaded fasteners.

Inspect mounting and rigging hardware regularly. Immediately replace any worn or damaged components.

LEOPARD Rigging Options

The table below summarizes the available rigging options for LEOPARD. For complete information about rigging hardware, including dimensions, weight, configuration, and load ratings, refer to the MG-LEOPARD/900 Assembly Guide (PN 05.243.080.01).

Model | Weight | Features | Required Quick-Release Pins | Required Shackles |

|---|---|---|---|---|

MG-LEOPARD/900 multipurpose grid (PN 40.243.080.01) | 60.5 lb (27.5 kg) | With some restrictions, flies up to 23 LEOPARDs at a 5:1 safety factor; supports mixed arrays of LEOPARDs and 900-LFCs without transition hardware; accommodates a variety of pickup configurations with four corner and 13 center pickup points; includes attachment points to accommodate brackets and adapters for lasers and inclinometers; can also be used for groundstacking | 5/16 in x 7/8 in (red button), PN 134.025, qty 10 included | 5/8-inch or 3/4-inch |

GROUNDSTACK DOWNTILT KIT: MG-LEOPARD/900 (PN 40.243.163.01) | 2 lb (0.9 kg) | Includes two angle feet that attach to the rear of the MG-LEOPARD/900 grid that add from 3-8 degrees of tilt to groundstacks | 5/16 in x 7/8 in (red button), PN 134.025, qty 0 included | — |

MVP motor Vee plate (PN 40.215.184.01) | 20 lb (9.1 kg) | Fine tunes the horizontal aim of arrays; compatible with MTG-LEO-M, MTG-LYON, MTG-1100, and MG-LEOPARD/900 grids | — | 3/4-inch or 7/8-inch |

MTF-LYON/LEOPARD transition frame (PN 40.232.140.01) | 71 lbs (32.2 kg) | With some restrictions, flies up to ten LEOPARDs at a 5:1 safety factor below LYON arrays for downfill; includes rear attachment points for pull-back; collapsible for easy transport on top of LEOPARD stacks | 7/16 in x 9/10 in (black button), PN 134.050, qty 0 included 5/16 in x 7/8 in, red button, PN 134.025, qty 8 included | 1/2-inch or 5/8-inch |

PBF-LEOPARD pull-back frame (PN 40.243.185.01) | 4.9 lb (2.2 kg) | Attaches to bottom of LEOPARD and 900-LFC arrays (to the bottom cabinet) and provides pull-back for extreme array downtilt; can also be used to add tilt to LEOPARDs groundstacked on the 900-LFC | 5/16 in x 5/8 in (black button), PN 134.024, qty 2 included | 1/2-inch |

MCF-LEOPARD caster frame (PN 40.243.130.01) | 37 lbs (16.8 kg) | Safely transports up to four LEOPARD cabinets, making it easy to assemble and disassemble arrays in blocks of four cabinets | 5/16 in x 5/8 in (black button), PN 134.024, qty 0 included | — |

Note

The MCF-LEOPARD caster frame does not include quick-release pins because it is secured with the quick-release pins included with the loudspeaker. The GROUNDSTACK DOWNTILT KIT: MG-LEOPARD/900 does not include quick-release pins because the angle feet are secured with the quick-release pins included with the grid.

Rigging Example, LEOPARD Array with Pull-Back

Rigging Example, Mixed Array with 900-LFCs and LEOPARDS

Rigging Example, LYON Array with LEOPARD Downfill

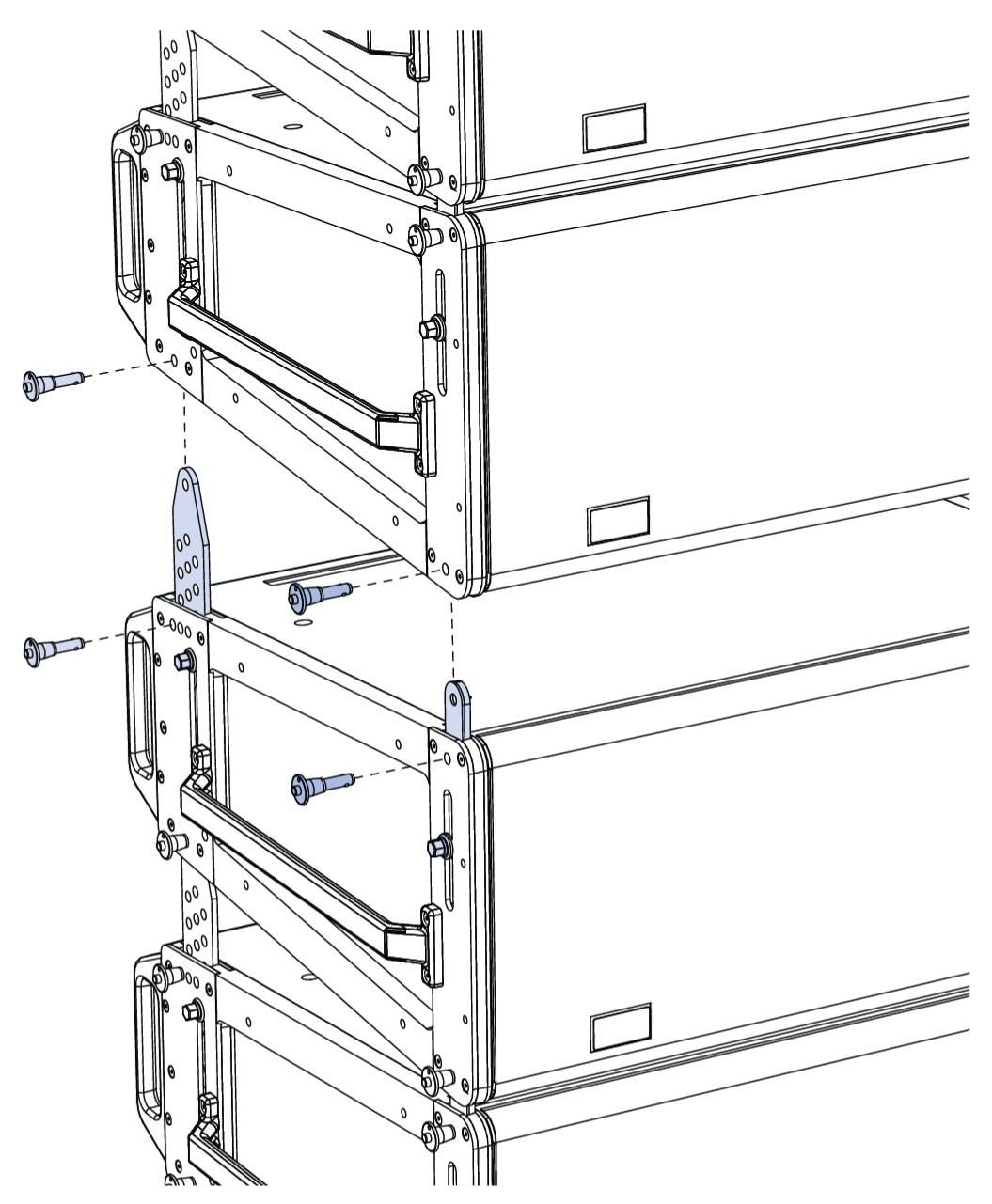

LEOPARD GuideALinks

LEOPARD is equipped with four captive GuideALinks and four mating links slots that link to adjacent LEOPARDs or 900-LFCs in flown and groundstacked arrays. Located at the top corners of the cabinet, GuideALinks extend up and into the link slots of the cabinet above it ([→ _bookmark35]Figure 16 and [→ _bookmark36]Figure 17), or into the link slots of the MG-LEOPARD/900 grid or MTF-LYON/LEOPARD transition frame. GuideALinks extend and retract with knobs and are secured with two quick-release pins: one each in the top and bottom cabinets. Each LEOPARD loudspeaker ships with eight 5/16 x 0.063-inch quick-release pins (black button) (PN 134.024).

LEOPARD GuideALinks with Quick-Release Pins, Exploded View

Caution

GuideALinks must be secured with the included quick-release pins. At no time should the weight of the loudspeaker rest on the GuideALink knobs when the links are fully extended (without the pins inserted). GuideALink knobs are for extending and retracting the links only.

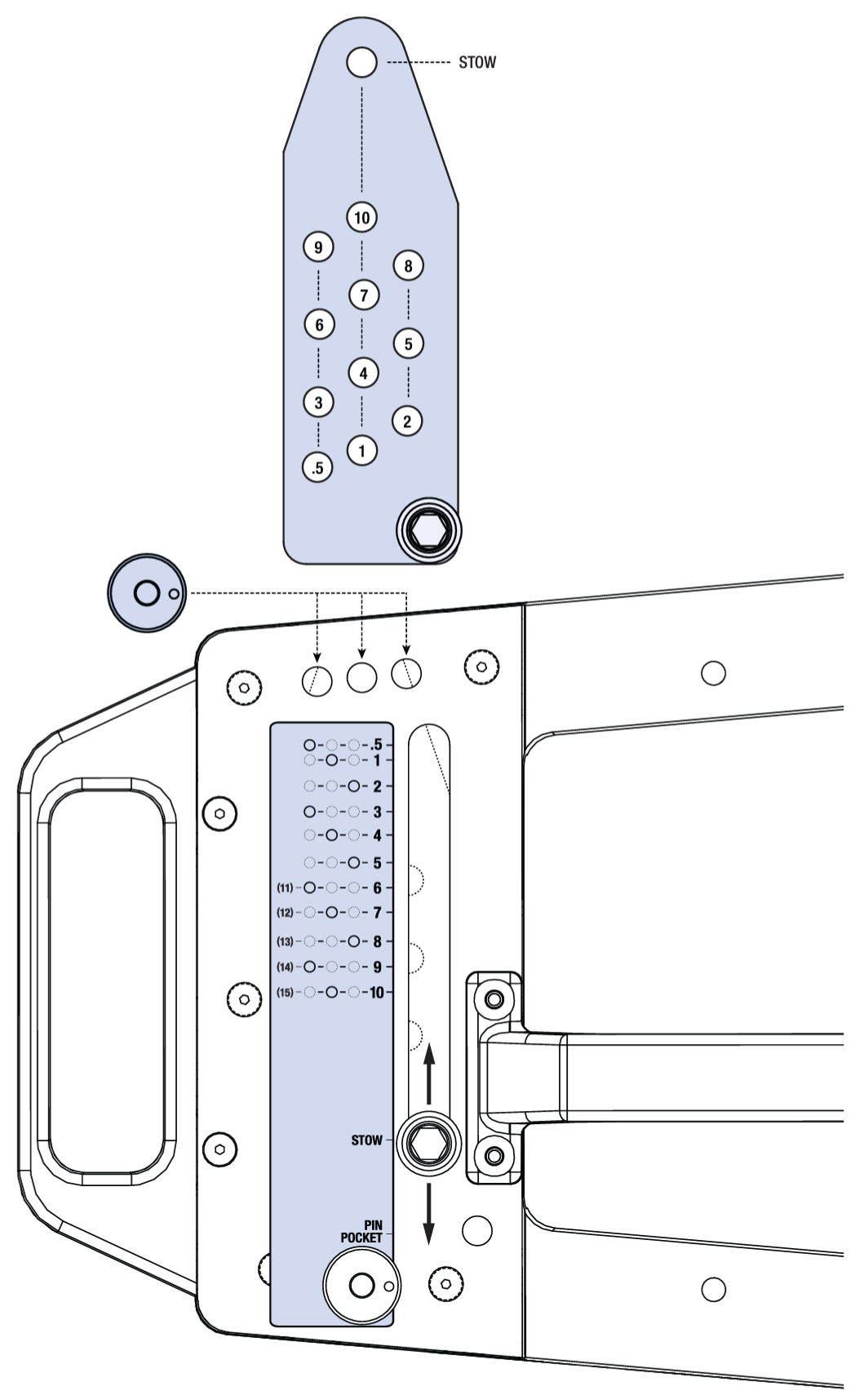

LEOPARD Splay Angles

Front GuideALinks attach at splay angles of 0 or +5 degrees. However, the front GuideALinks should almost always be attached at 0 degrees, to ensure that coverage between

linked cabinets is continuous. When attached at 0 degrees, the front GuideALinks act as a pivot point between the linked LEOPARDs, with the splay angle between the units determined by the rear GuideALink positions. When attached at +5 degrees, the front GuideALinks add 5 degrees to the splay angle configured with the rear GuideALinks, making it possible to achieve splay angles of 11 to 15 degrees. To stow the front GuideALinks, move them all the way down to STOW and pin them.

Tip

Wide splay angles of 11 to 15 degrees should only be used for downfill coverage, or for steering coverage away from structures like balconies.

LEOPARD GuideALinks (Exposed) Attached at 0.5 Degrees

Rear GuideALinks attach at splay angles of 0.5 to 10 degrees. The labels next to the rear GuideALinks indicate the splay angle between cabinets and provide a guide for which of the three pinning positions to use to secure the links, as shown in the figure below. As the links are moved down, the splay angle increases. To stow the rear GuideALinks, move them all the way down to STOW and pin them to the center pin position.

Note

The splay angles listed on the GuideALink labels are for relative angles between the center axes of the linked units. For example, setting the GuideALinks to 5 degrees yields a 5-degree downtilt of the lower unit to the upper unit. How the loudspeakers relate to the floor, stage, and seating angles in the venue depends on the orientation of the grid, the angles of the loudspeakers in the array above them, and other factors. MAPP prediction software should be used to calculate optimum splay angles for loudspeakers and to predict coverage patterns for arrays.

LEOPARD Rear GuideALinks Label

Note

For more information on GuideALink configurations, refer to the MG-LEOPARD/900 Assembly Guide (PN 05.243.080.01).

LEOPARD Splay Angles for Top Flown Cabinets

When flying LEOPARDs below the 900-LFC, MG- LEOPARD/900 grid, or MTF-LYON/LEOPARD transition frame, splay angles of –4.5 to +10 degrees are possible for the top cabinet with the GuideALink configurations listed in the table below.

Rear GuideALinks Set To | Front GuideALinks Set To | Resulting Angle of Attachment |

|---|---|---|

.5° | 0° | –4.5° |

1° | 0° | –4° |

2° | 0° | –3° |

3° | 0° | –2° |

4° | 0° | –1° |

5° | 0° | 0° |

6° | 0° | 1° |

7° | 0° | 2° |

8° | 0° | 3° |

9° | 0° | 4° |

10° | 0° | 5° |

6° | +5° | 6° |

7° | +5° | 7° |

8° | +5° | 8° |

9° | +5° | 9° |

10° | +5° | 10° |

Note

When flying LEOPARDs from the MG-LEOPARD/900 grid, a splay angle of 0 degrees is recommended for the top cabinet (rear GuideALinks set to 5, front GuideALinks set to 0) to ensure that the cabinet aligns with any lasers or inclinometers mounted on the grid. To add tilt to the top cabinet, the actual grid should instead be tilted with motors attached to the front and rear of the grid. If just one motor is available, you can attach it to one of the 13 center pickup points offset from the center of the grid to achieve the desired tilt.

System Design and Integration Tools

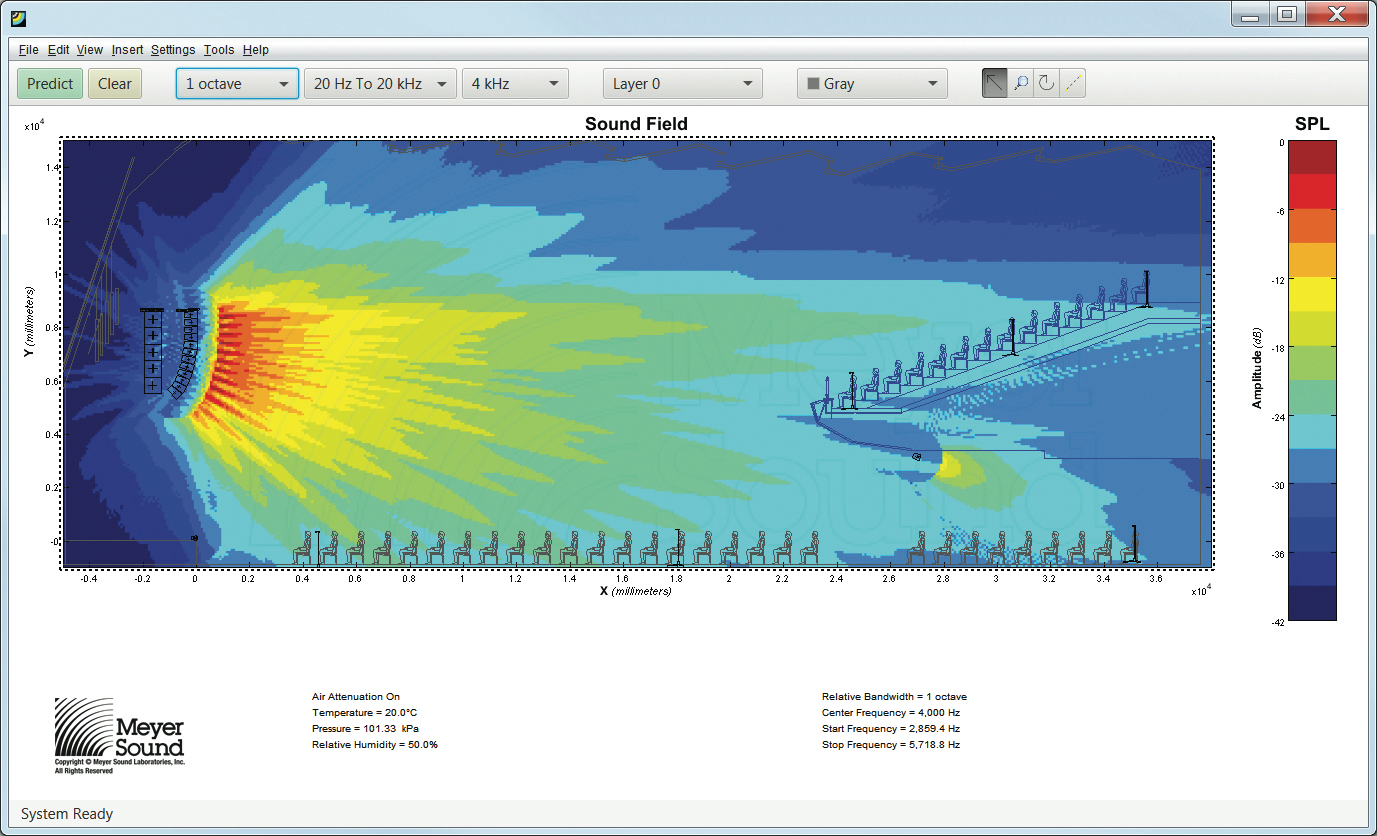

MAPP System Design Tool

MAPP is a powerful, cross-platform application for accurately predicting the coverage pattern, frequency response, phase response, impulse response, and SPL capability of single or arrayed Meyer Sound loudspeakers.

MAPP System Design Tool

Whether planning for fixed installations or for tours with multiple venues, you can use MAPP to accurately predict the appropriate loudspeaker deployment for each job, complete with coverage data, system delay and equalization settings, rigging information, and detailed design illustrations. MAPP’s accurate, high-resolution predictions ensure that systems will perform as expected, thereby eliminating unexpected coverage problems and minimizing onsite adjustments.

The key to the accuracy of MAPP’s predictions is Meyer Sound’s exhaustive database of loudspeaker measurements. Performance predictions for each loudspeaker are based on 720 1/48th-octave-band measurements taken with a SIM audio analyzer in the Meyer Sound anechoic chamber. The extraordinary consistency between Meyer Sound loudspeakers guarantees that predictions from MAPP will closely match their actual performance.

MAPP client software lets you configure Meyer Sound loudspeaker systems and define the environment in which they operate, including air temperature, pressure, humidity, and even the location and composition of surfaces. You can also import CAD (.DXF) files containing detailed venue information to act as a visual aid.

MAPP prediction requests are sent by the client software to Meyer Sound servers, where complex, high-resolution (magnitude and phase) polar data is processed with sophisticated acoustical prediction algorithms. The resulting predictions are then displayed in the MAPP client software.

With MAPP, you can:

Simulate different loudspeaker configurations to refine system design and determine the best coverage for intended audience areas

Monitor loudspeaker interactions to locate constructive and destructive interferences so that loudspeakers can be re-aimed and repositioned as necessary

Place microphones anywhere in the sound field and predict loudspeaker frequency response, phase response, and sound pressure levels as measured at each microphone position

Determine delay settings for fill loudspeakers using the Inverse Fast Fourier Transform feature

Preview the results of Galileo or Galileo Callisto processing to determine optimum settings for the best system response

Automatically calculate load information for arrays to determine rigging capacity, front-to-back weight distribution, and center of gravity location

Generate and export system images and full-system PDF reports for client presentations

MAPP Capabilities

With MAPP, the user can:

Simulate different loudspeaker configurations to refine system designs and determine the best coverage for intended audience areas

Model loudspeaker interactions to locate constructive and destructive interferences so that loudspeakers can be re-aimed and repositioned as necessary

Place microphones anywhere in the Model View space and predict loudspeaker frequency response, phase response, and sound pressure levels at each microphone position

Determine delay settings for fill loudspeakers using the Inverse Fast Fourier Transform and phase response feature

Preview the results of signal processing to determine optimum settings for the best system response

Automatically calculate load information for arrays to determine necessary minimum rigging capacity, front-to-back weight distribution, and center of gravity location

Generate and export system images and system PDF reports for client presentations

Synchronize GALAXY processor output channel settings in real-time with virtual or real GALAXY units, allowing in-the-field changes to be predicted during system alignments

Galileo GALAXY Network Platform

The Galileo GALAXY Network Platform is a sophisticated loudspeaker management tool for controlling all Meyer Sound speaker types. The GALAXY loudspeaker processor extends a high level of audio control in driving and aligning loudspeaker systems with multiple zones. It provides a powerful toolset for corrective equalization (EQ) and creative fine-tuning for a full range of applications from touring to cinema.

Users can readily program the GALAXY processor using Compass software running on a host computer or via the Compass Go application for the iPad. Connecting MAPP to the GALAXY processor will also allow the user to push output channel settings created in MAPP as a starting point. Compass Control Software includes custom-designed settings for each family of speakers, as well as to integrate families together. For example, the Product Integration feature matches the phase characteristics between Meyer speaker families to ensure the most coherent summation.

Processing tools for inputs and outputs include delay, parametric EQ, and U-Shaping EQ. Output processing also includes polarity reversal, Low-Mid Beam Control (LMBC), atmospheric correction, and All-Pass filters.

The built-in summing and delay matrices allow a user to easily assign gain and delay values, respectively, at each cross point. This capability greatly facilitates using one loudspeaker to satisfy multiple purposes.

Front panel controls let a user intuitively and quickly operate a GALAXY processor without a computer during live use.

The GALAXY 408, GALAXY 816, and GALAXY 816-AES3 processor versions have the same audio processing capability with different I/O.

Meyer Sound Weather Protection

The Weather Protection option from Meyer Sound is intended to increase the useful life of Meyer Sound loudspeakers when they are installed outdoors and exposed to different and often harsh weather conditions. Our Weather Protection includes a penetrating treatment to raw wood, use of special primers, and plating on all steel parts used (or alternatively, the use of stainless steel hardware). Weather Protection is designed to prevent malfunctions caused by harsh operating environments and slows the accelerated wear and tear that occurs in outdoor environments.

When Is Weather Protection Advisable?

Weather Protection is strongly recommended for all permanent outdoor installations where loudspeakers are directly exposed to the elements. This includes desert and semi-arid climates, where protection against dust and sand is important, and where infrequent rainstorms can contribute to deterioration of loudspeaker components.

Weather Protection is also recommended when the loudspeakers are sheltered from direct exposure to precipitation but are nevertheless exposed to prolonged high humidity, fog or mist. Examples would be installations on covered outdoor terraces or pavilions

Weather Protection is further advisable for portable or touring systems when any significant outdoor use is anticipated. Even though standard procedures may call for using external protective measures, these are often not implemented in time to prevent moisture intrusions that could lead to premature performance degradation of the loudspeaker.

Climate Variation and Owner Maintenance

The wear and tear on a loudspeaker will vary significantly with different climatic conditions. For example, a weather protected loudspeaker installed in a sunlight-exposed location on an ocean pier will experience much harsher conditions than a loudspeaker in a similar installation that is shaded by trees and exposed only to rainfall. The constant exposure to direct UV radiation and salt air environment will cause a loudspeaker to wear more quickly than one with partial UV shielding and exposed only to freshwater moisture.

Wear can eventually affect the performance of the loudspeaker. It also affects aesthetics. For example, in salt air environments, the exterior grille can quickly show signs of oxidation, causing unsightly discoloration.

Apart from selecting suitable weather protection, the progress of wear and tear on the loudspeaker can be slowed by a regular schedule of inspection and cleaning. This maintenance is particularly necessary in harsh environments. Inspection and cleaning should include routine removal of any visible oxidation or environmental particulates, as these can accelerate metal corrosion or decay of the cabinet. If installed loudspeakers are not in use for an extended period, exterior protection or temporary removal and storage of the loudspeakers should be considered.

Benefits of Weather Protection

There are several benefits to selecting the Meyer Sound Weather Protection option:

Functionality - Weather Protection prolongs the service life of the loudspeaker by preventing premature degradation of internal components.

Safety - Weather Protection lessens the chance of electrical malfunctions or structural failures.

Warning

IT IS THE RESPONSIBILITY OF PURCHASERS/USERS/OPERATORS TO SELECT WEATHER PROTECTION WHEN APPROPRIATE FOR THEIR USE AND TO PERIODICALLY INSPECT THEIR LOUDSPEAKER INSTALLATIONS FOR ANY DETERIORATION THAT MAY LEAD TO SAFETY CONCERNS.

Aesthetics - Weather Protection slows wear and tear on the exterior of the loudspeaker in harsh conditions. Early signs of wear and tear on the exterior of the loudspeaker indicate over-exposure to the elements.

Standards Compliance - Weather Protection helps in meeting IP ratings for loudspeakers. IP ratings are an internationally recognized standard often used in installations involving our products. A further explanation of IP ratings is given in the IP Ratings.

Weather Protection Components

Standard Weather Protection

Meyer Sound designs toward an IP rating of IPX4 (see IP Ratings) for Standard Weather Protection, which includes the following components:

Wood treatment — Prior to cabinet manufacturing, the raw wood receives a special treatment that penetrates and stabilizes the wood fibers to withstand a wide range of temperatures and exposure to extreme humidity.

Cabinet finishing — The assembled cabinets receive a highly impervious finish that includes a sealing primer and a finishing topcoat. The coatings are applied on both surfaces, with one coat on the interior and two on the exterior. The final step is a two-part modified acrylic urethane similar to that used in military applications.

Driver treatment — All cone drivers are coated with a water-resistant sealant.

Exterior protection — Grille frames are coated to resist corrosion, and all components that mount to the cabinet use custom gaskets and stainless steel fasteners.

Removable rain hood — The rain hood is designed to shield connectors even in wind-driven rain.

Ultra Weather Protection

For installations in extremely harsh environments, Meyer Sound offers an Ultra Weather Protection option on a limited number of loudspeaker models. (For a list of products offered with this option, please contact Meyer Sound.) Meyer Sound designs toward an IP rating of IPX5 for Ultra Weather Protection, which includes all of the components of standard Weather Protection, plus the following:

Extended cabinet finishing with extra thick proprietary coatings

Special printed circuit board treatments

Use of corrosion-resistant hardware

Ultra Weather Protection is recommended for applications where loudspeakers will experience exposure to a salt air environment or chemicals, that have no sheltering from corrosive spray or UV exposure, and that cannot be covered or removed during their service life. Examples would include cruise ship exterior areas, ocean-side visitor attractions, swimming pool areas, and themed attractions with wind-carried water spray.

Installation Practices

Meyer Sound assumes normal and accepted installation practices are used when installing Meyer Sound Loudspeakers outdoors. Deviation from such practices may cause weather protection to be ineffective and void the warranty for the loudspeaker.

Examples of unacceptable and acceptable installation practices include:

Loudspeakers installed outdoors should not face upward.

Loudspeakers with a rain hood should be installed in such a way that the rain hood opening is not facing any direction but down.

Meyer Sound-supplied rigging components should not be modified (for example, by drilling additional holes in a MUB for mounting to a wall). When an installer/integrator modifies a Meyer Sound supplied rigging component to support their installation method, it is considered compromised and out of warranty.

All loudspeaker cabling must be installed with a "drip-loop" or equivalent method to ensure that rain/ water is NOT wicked toward the loudspeaker.

If in doubt about an installation method, contact Meyer Sound Technical Support for assistance.

Always discuss the environmental conditions of your Meyer Sound installation with your Sales Manager, and verify the availability of Weather Protection for your selected loudspeaker models. The Sales Manager, together with Technical Support, will verify the appropriate level of weather protection for the loudspeakers and related rigging hardware.

IP Ratings

IP stands for "Ingress Protection." The current format for expressing an IP rating is a 2-digit code. The first digit of an IP rating represents protection from solid objects. The second digit of an IP rating represents protection from water or moisture. The table below provides a chart of IP ratings and the corresponding definitions of the rating.

Note

IP ratings only apply to the "ENCLOSURE." A loudspeaker is considered an enclosure and as such we can apply an IP rating to it. Rigging hardware is not an enclosure and therefore IP ratings do not apply. Also, cable and cable-mount connectors used to connect to the loudspeaker are NOT part of the enclosure and therefore not part of the IP rating. Only the chassis-mounted part of the connector is considered part of the enclosure.

First Digit (Protection against solid objects) | Definition | Second Digit (Protection against liquids) | Definition |

|---|---|---|---|

X | Characteristic numeral is not required to be specified. | X | Characteristic numeral is not required to be specified. |

0 | No protection | 0 | No protection |

1 | Protected against solid objects over 50mm. | 1 | Protected against vertically falling drops of water. |

2 | Protected against solid objects over 12 mm. | 2 | Protected against direct sprays up to 15° from the vertical. |

3 | Protected against solid objects over 2.5mm. | 3 | Protected against direct sprays up to 60° from the vertical |

4 | Protected against solid objects over 1 mm. | 4 | Protected against direct sprays from all directions. Limited ingress permitted |

5 | Protected against dust. Limited ingress permitted. | 5 | Protected against low-pressure jets of water from all directions. Limited ingress permitted. |

6 | Totally protected against dust. | 6 | Protected against strong jets of water from all directions. Limited ingress permitted. |

7 | Protected against the effect of temporary immersion between 15cm and 1m. | ||

8 | Protected against the effect of long-term submersion of 1m or more. |

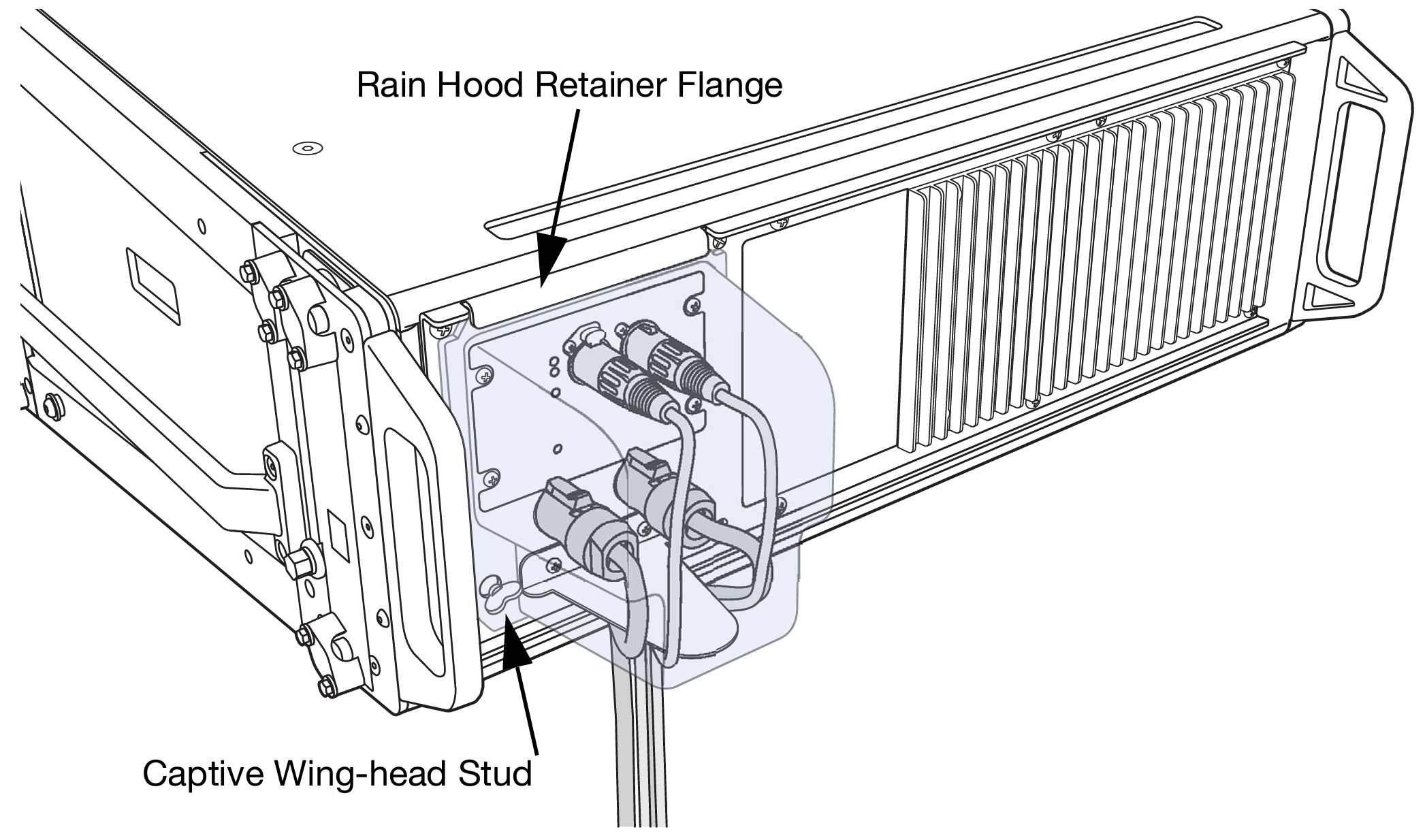

LEOPARD Rain Hoods

LEOPARD Quick-clip Rigid Rain Hood

Weather-protected LEOPARDs include a quick-clip removable rain hood for indoor/outdoor touring and sheltered outdoor installations.

The LEOPARD quick-clip removable rain hood (Figure 24) is easily attached and removed with its two winghead studs.

Connect any required cables to the LEOPARD loudspeaker

Attach the rain hood to the user panel, slipping it under the rain hood retainer flange at the top of the user panel and securing it to the center of the panel with its two winghead studs.

LEOPARD with Quick-Clip Rain Hood

Make sure to tighten the winghead studs one quarter turn so they fully lock

LEOPARD Collapsible Rain Hood

Another option for weather-protected LEOPARDs is the collapsible rain hood.

The LEOPARD collapsible rain hood (Figure 24) is easily attached and removed with its two screws

Slip the rain hood under the rain hood retainer flange at the top of the user panel.

Secure the rain hood at the bottom of the panel with the two provided 6-32 x 0.75-inch stainless steel screws.

Make sure to tighten the screws to create a good seal against the user panel. The recommended torque value for rain hood screws is

LEOPARD with Collapsible Rain Hood

Detach the Velcro straps and extend the rain hood.

Extend the lower flap for splash protection.

Attach any required cables to the LEOPARD

The clear windows let you easily locate the connectors on the user panel.

To stow the rain hood, reverse the steps.

Caution

There is only one proper loudspeaker orientation once the rainhood is installed. The loudspeaker must be oriented so that all cabling exits from the bottom of the rain hood.

The weather-protected LEOPARD must be mounted with a 0° tilt, or preferably with a slight down-tilt. This angle shields the driver from the elements and does not allow water to accumulate. Do not tilt the cabinet up, as the drivers and cabinet will accumulate water.

Note

Weather Protected units using either of the LEOPARD/900-LFC Rain Hoods are rated IP44 for water intrusion.

ULTRA Weather Protection Version

Ultra Weather Protection is recommended for applications where loudspeakers will experience exposure to a salt air environment or chemicals, that have no sheltering from corrosive spray or UV exposure, and that cannot be covered or removed during their service life. Examples would include cruise ship exterior areas, ocean-side visitor attractions, swimming pool areas, and themed attractions with wind-carried water spray.

For installations in extremely harsh environments, Meyer Sound offers an IPX5-rated, Ultra Weather Protection version of the LEOPARD loudspeaker, which includes all of the components of standard Weather Protection, plus the following:

Extended cabinet finishing with extra thick proprietary coatings

Special printed circuit board treatments

Improved corrosion-resistant coatings and materials on select metallic components

Rigging changes for improved corrosion resistance

Rain hood splash guard for improved water resistance

The table bekow provides a list of the accessories and user-accessible hardware component differences for LEOPARD loudspeakers that ship from the factory as Ultra Weather Protection versions.

LEOPARD Accessory/Part | UW LEOPARD Accessory/Part | Comment |

|---|---|---|

MG-LEOPARD/900-LFC Grid (PN 40.243.080.01) | MG-LEOPARD/900-LFC UW Grid, white (PN 40.243.180.05) or MG-LEOPARD/900-LFC UW Grid, black (PN 40.243.180.06) | See entries on “Grid to Loudspeaker Fasteners” and “Blanking Screws” in the UW LEOPARD Accessory/Part Column. NoteUW grids require the GROUNDSTACK KIT UW (40.243.163.05 or 40.243.163.06) in order to be usable for ground-stacking. |

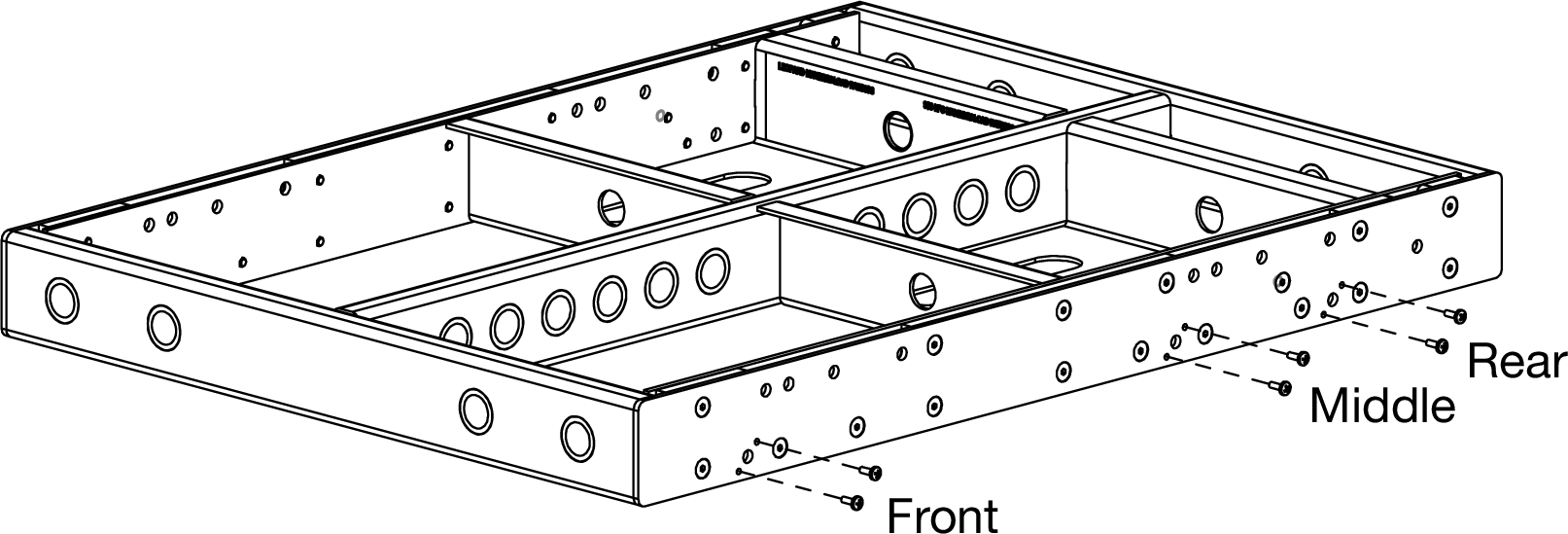

Not applicable | MG-LEOPARD/900-LFC Blanking Screws 8-32 x 0.5-inch pan head Phillips stainless steel screw (PN 101.167), qty 12 | Two of these “blanking screws” are inserted around each grid pinhole location to prevent corrosion at unused pin locations. Those at locations where the speaker links will be attached must be removed before attaching a speaker to the grid. See the first figure below the table. NoteFor the LEOPARD loudspeaker, the front and middle blanking screws must be removed. For the 900-LFC loudspeaker, the front and rear blanking screws must be removed. |

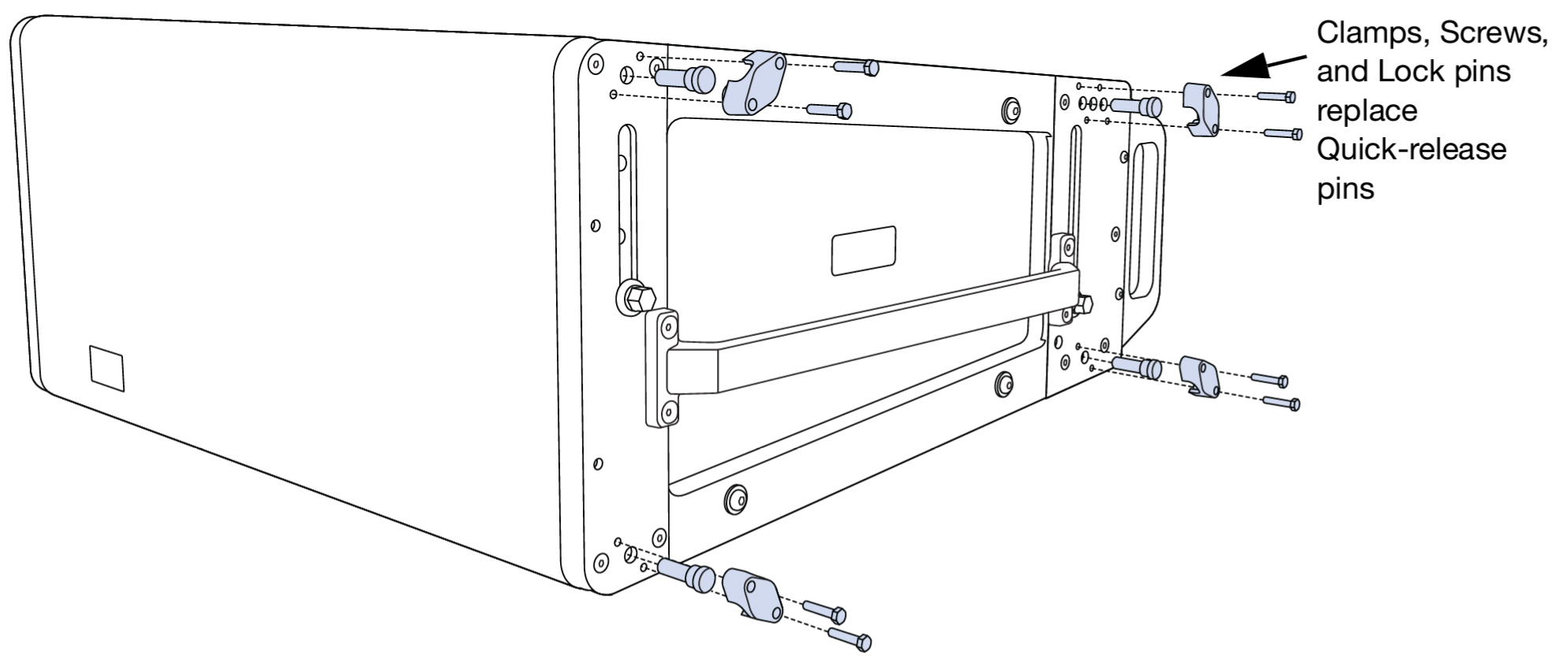

MG-LEOPARD/900-LFC Grid to Loudspeaker Quick-release pins (with lanyard) Red 5/16 in x 0.875 in with 6-inch lanyard (PN 134.025), qty 10 | MG-LEOPARD/900-LFC Grid to Loudspeaker Fasteners UW lock pin clamp, 5/16-inch with gasket, qty 4 (PN 45.010.506.05), white OR (PN 45.010.506.06), black Hex head screw with washer 8-32 x 3/4-inch, qty 12 (PN 45.010.934.05), white OR (PN 45.010.934.06), black CautionThese screws have a ! pre-applied thread-locking patch and cannot be reused. UW lock pin 5/16-in x 0.63-inch (PN 61.010.504.01), qty 4 | The clamps, screws, and lock pin replace the quick-release pins (with lanyard). Torque screws to 12 in-lb (1.36 N·m). |

LEOPARD Loudspeaker to Loudspeaker quick-release pins Black 5/16 in x 0.63 in (PN 134.024), qty 8 | LEOPARD Loudspeaker to Loudspeaker Fasteners UW lock pin clamp, 5/16-inch with gasket, qty 8 (PN 45.010.506.05), white OR (PN 45.010.506.06), black Hex head screw with washer 8-32 x 3/4-inch, qty 20 (PN 45.010.934.05), white OR (PN 45.010.934.06), black UW lock pin 5/16-in x 0.63-inch (PN 61.010.504.01), qty 8 | The clamps, screws, and lock pin replace the quick-release pins (with lanyard). See the second figure below the table. Torque screws to 12 in-lb (1.36 N·m). |

GROUNDSTACK KIT: MG- LEOPARD/900-LFC (PN 40.243.163.01) (Kit does not include quick-release pins because the angle feet are secured with the quick-release pins included with the grid.) | GROUNDSTACK KIT: MG-LEOPARD/900-LFC UW, white (PN 40.243.163.05) or MG-LEOPARD/900-LFC UW, black (PN 40.243.163.06) | These UW kits include: MG-LEOPARD/900-LFC Grid Tilt Assembly (PN 45.243.163.05 or 45.243.163.06), qty 2 LEOPARD UW/900-LFC UW Grid Links, (PN 61.243.191.05 OR 61.243.191.06), qty 4. Shoulder bolts 5/16x1-inch with 1/4-20 thread (PN 101.529), qty 10 Hex Nut, 1/4-20 thread, self-locking (PN 109.107), qty 10. The shoulder bolts and hex nuts replace the grid quick-release pins. |

Blanking Screws (6 per side) to Prevent Corrosion at Unused Pin Locations for Ultra Weather Protection Grid

Ultra Weather Protection LEOPARD Loudspeaker Version has Clamps, Screws, and Lock pins that replace standard version quick-release pins

Caution

The use of corrosion-resistant material reduces the strength of the LEOPARD UW loudspeaker compared to the standard or weather-protected versions. LEOPARD UW loudspeaker versions should not be rigged together with LEOPARD standard or weather-protected loudspeaker versions. Contact Meyer Sound for guidance on loading limitations.

Ultra LEOPARD/900-LFC Rain Hood Kit

The ULTRA-weather-protected LEOPARD/900-LFC kit includes a quick-clip removable rain hood. The Ultra Weather Protection LEOPARD/900-LFC Rain Hood Kit includes the following parts:

LEOPARD/900-LFC Quick Clip Rain Hood with Splash Shield Assembly (PN 45.243.241.01)

LEOPARD Rain Hood Baffle (PN 64.243.104.01)

2 pan head Phillips 6-32 x 0.25-inch 316 stainless-steel screws (PN 101.405)

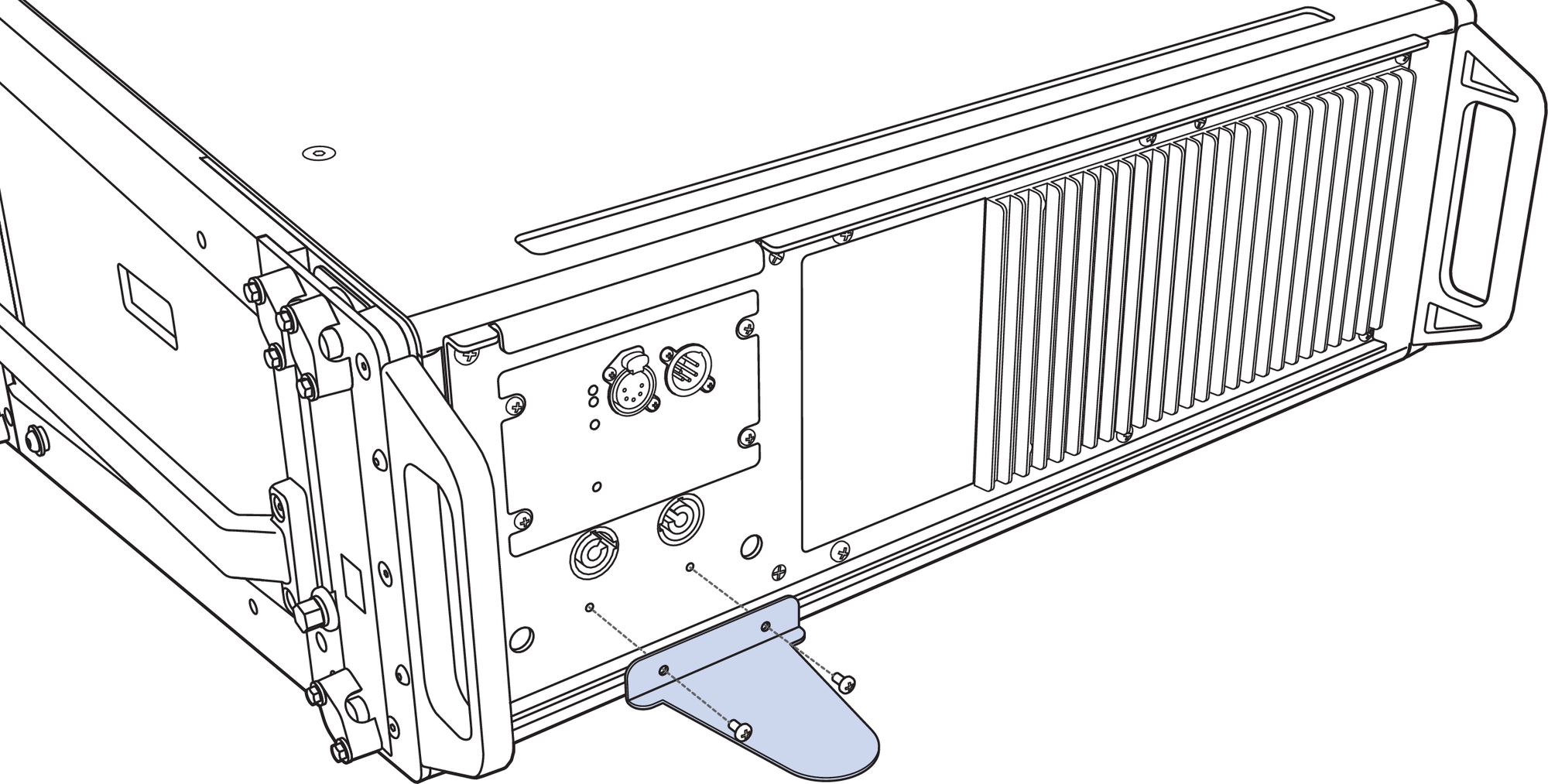

Rain Hood Baffle Installation

Gather the LEOPARD/900-LFC Rain Hood Baffle (PN 64.243.104.01) and the two pan head Phillips 6-32 x 0.25-inch stainless steel screws (PN 101.405).

Turn the loudspeaker so that the rear is accessible.

Locate the two screw holes beneath the powerCON connectors on the user panel (left side of the loudspeaker).

Attach the Baffle in the orientation shown in Figure 27 using the two provided screws. The recommended torque value for both screws is 10–12 in-lbs (1.1–1.4 N·m).

Attaching Rain Hood Baffle to LEOPARD Loudspeaker User Panel

Routing Cables and Attaching Rain hood

After installing the baffle, install the necessary audio and power cables.

Attach the rain hood to the user panel, slipping it under the rain hood retainer flange at the top of the user panel.

Route the cables through the rain hood on either side of the baffle and through the bottom of the rain hood.

Push the rain hood flush against the loudspeaker.

Secure it to the loudspeaker by giving the two captive wing-head stud fasteners on either side of the rain hood a quarter turn, so they fully lock.

Routing Signal and Power Cables Through Rain Hood and Around Baffle

Note

Ultra Weather Protected units using the LEOPARD/900-LFC UW Rain Hood are rated IPX5 for water intrusion.

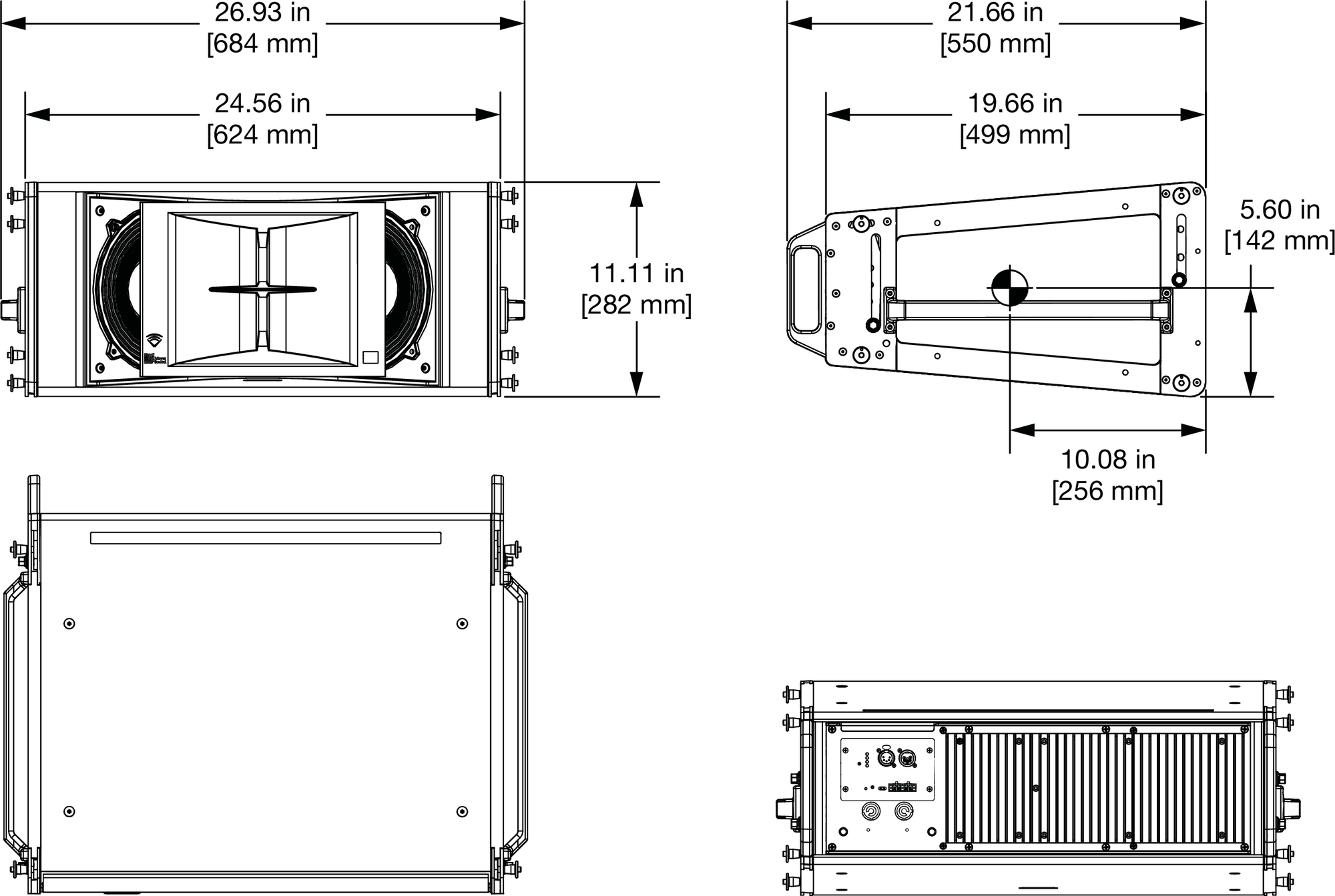

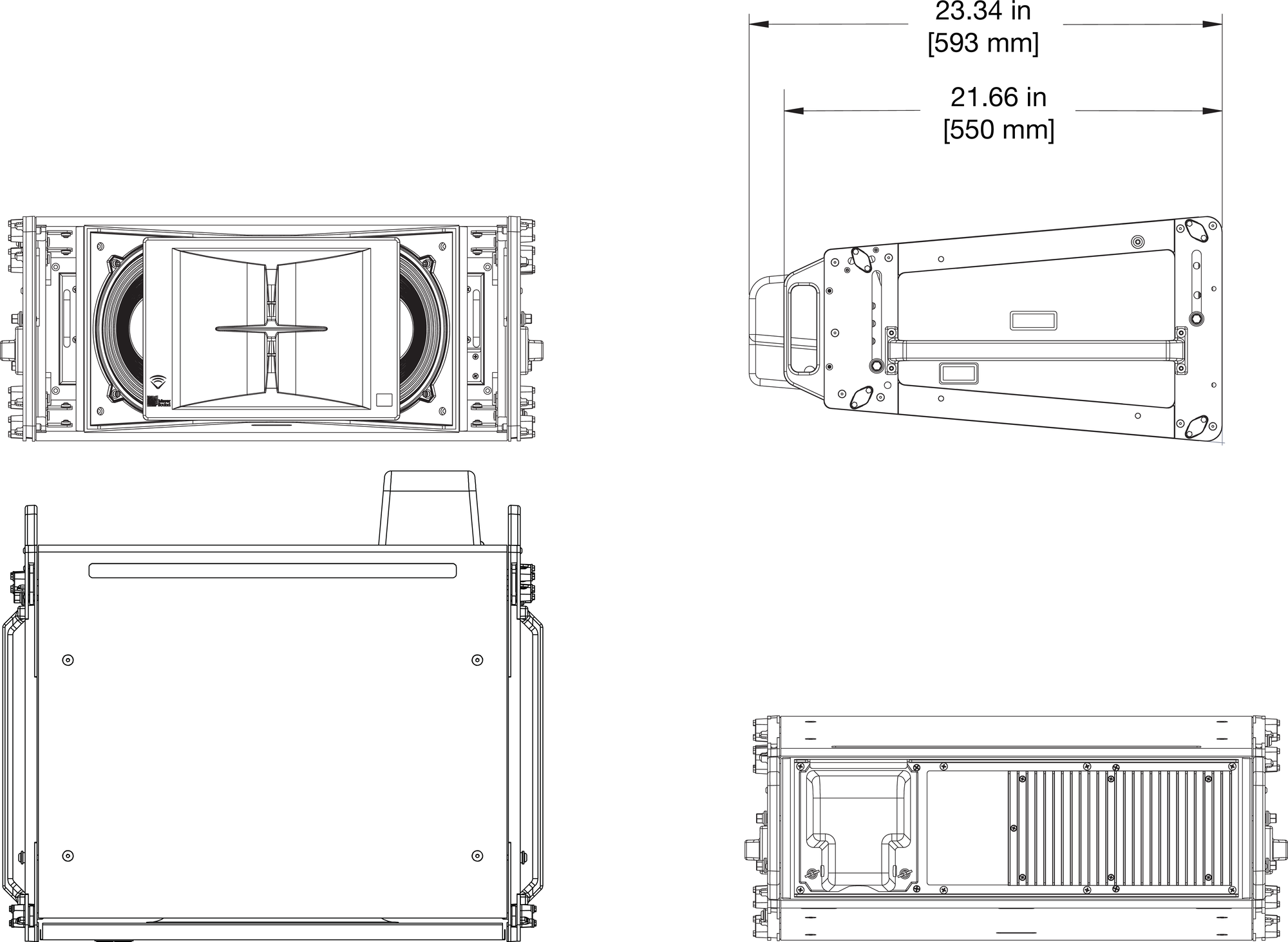

LEOPARD Dimensions

LEOPARD and LEOPARD-M80 Horn Visual Differences

ULTRA Weather Protection LEOPARD with Rain Hood Dimensions

Federal Communications Commission (FCC) Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at their own expense.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Industry Canada Compliance Statement

This Class A digital apparatus complies with Canadian ICES-003.

Avis De Conformité à La Réglementation D'Industrie Canada

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

EN 55032 (CISPR 32) Statement

Warning

This equipment is compliant with Class A of CISPR 32. In a residential environment, this equipment may cause radio interference.